Introduction

The logistics industry is one of those sectors that have seen few technological advancements lately. It’s a paper-intensive industry that relies on manual entry of data by humans. But with manual entries comes errors. Thus, the industry seeks technological solutions that can help improve accuracy and efficiency in operations.

Optical Character Recognition (OCR) is a technology that converts different types of documents into text formats that can be read and interpreted by software. OCR is primarily used to automate data entry and minimize the human-made errors in doing so. It typically achieves an accuracy level of 99% or higher.

The logistics industry has traditionally been paper-intensive for storing data. With the use of OCR, the logistics sector can automate data capturing and extraction from various objects and vehicles. This data is directly stored in the inventory management system. The entire process improves accuracy and expedites processing times.

In this blog, we’ll get to know what OCR exactly is and how companies are unlocking new levels of efficiency with it.

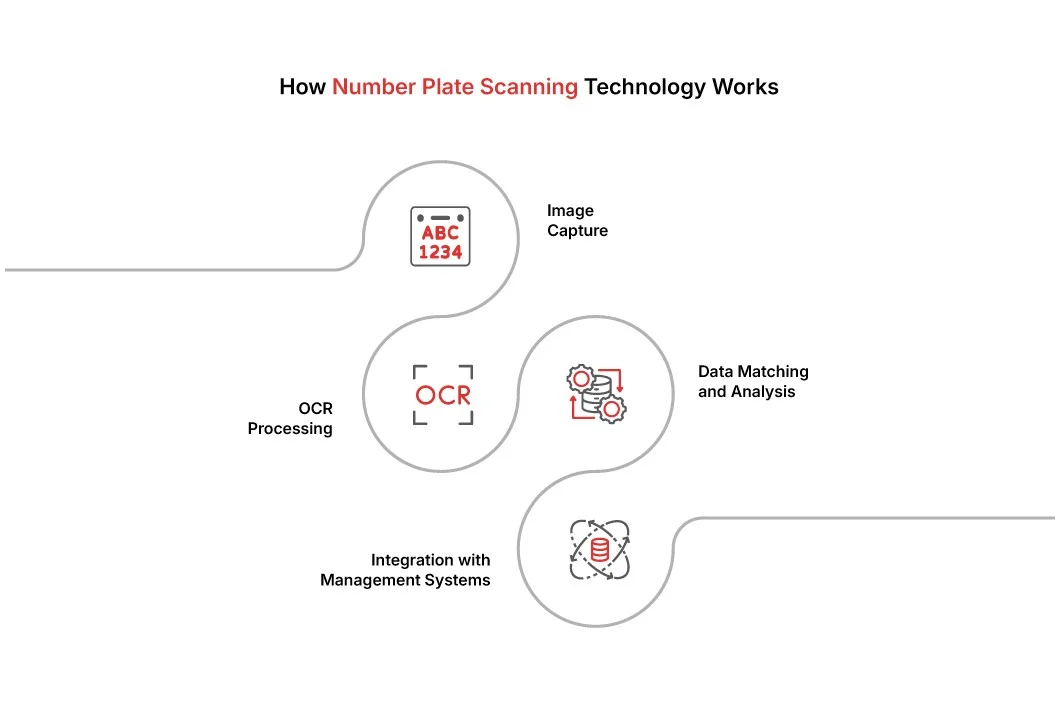

How OCR Works in Logistics

The OCR process consists of several key components. Let’s go through each one of them to understand how it can transform industries like logistics.

1. Text capture

Firstly, the physical documents are scanned using cameras. With the advancements in hardware, today even smartphones can capture images for the OCR software. Meaning, logistics personnel can easily digitize important records using their smartphones.

2. Text recognition

The scanned images are analyzed by algorithms to identify characters and symbols. Advanced OCRs are very versatile, they can recognize multiple languages and fonts.

3. Data extraction

Data extraction uses customized rules to guide the system around pulling relevant information only from the text.

4. Data integration

Lastly, the extracted information is fed into logistics management systems like WMS and ERP. Modern OCRs are equipped with APIs for easy integration to facilitate the integration. The automation here reduces manual work and in turn, eliminates the errors that come along.

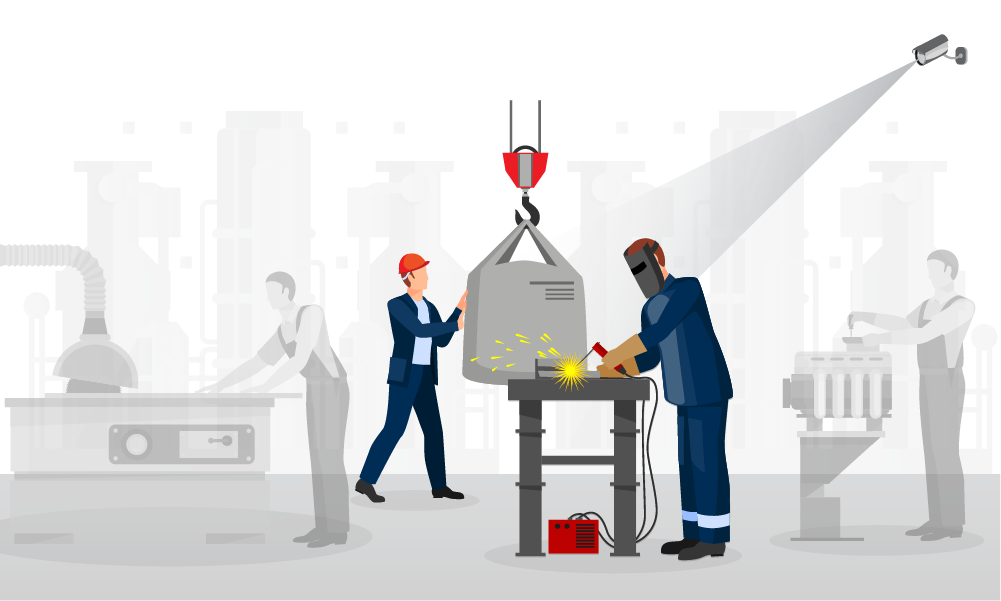

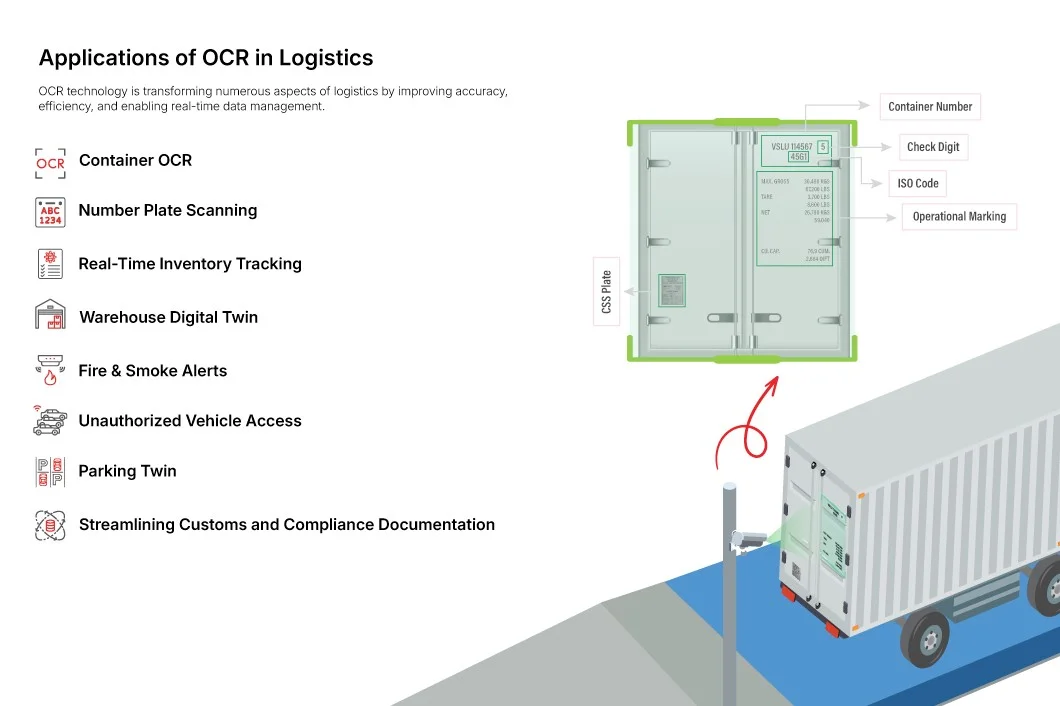

Applications of OCR in Logistics

OCR technology is transforming numerous aspects of logistics by improving accuracy, efficiency, and enabling real-time data management.

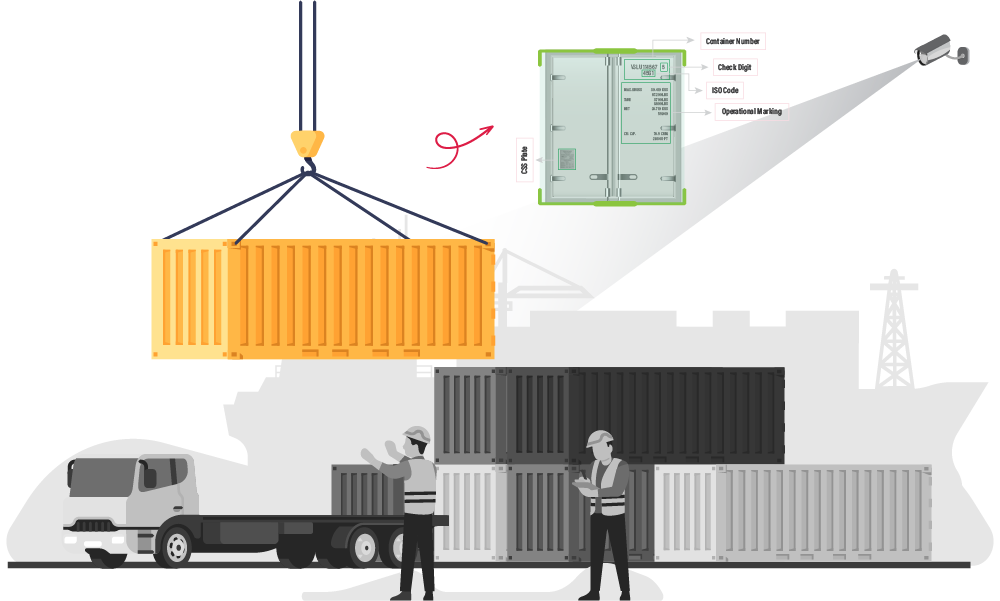

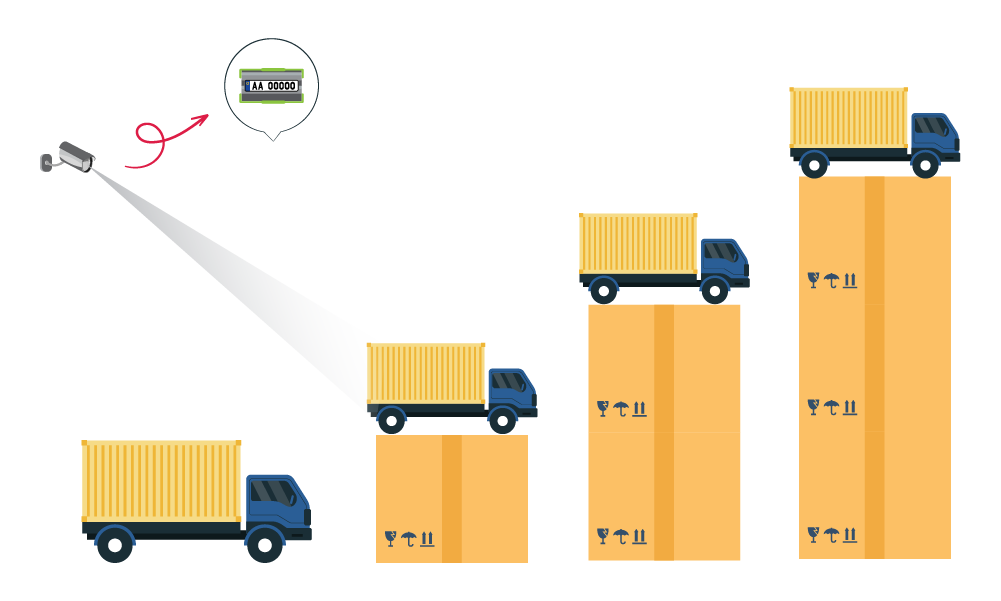

Container OCR

Container OCR systems are used to identify and track shipping containers by reading their unique identification numbers. It requires cameras at the port entry or mounted on cranes for scanning the containers as they move. It reduces manual errors and boosts port operations.

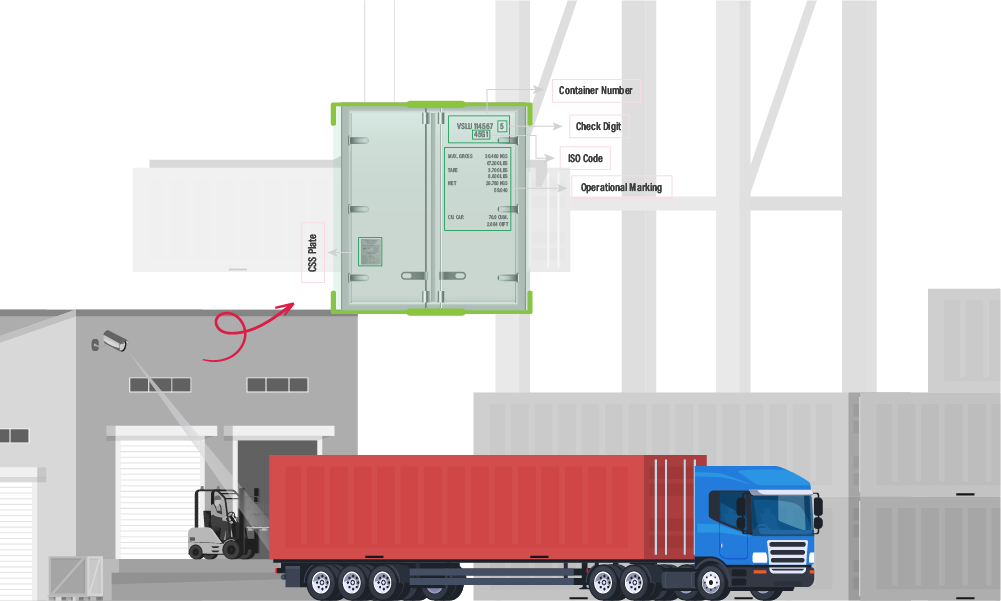

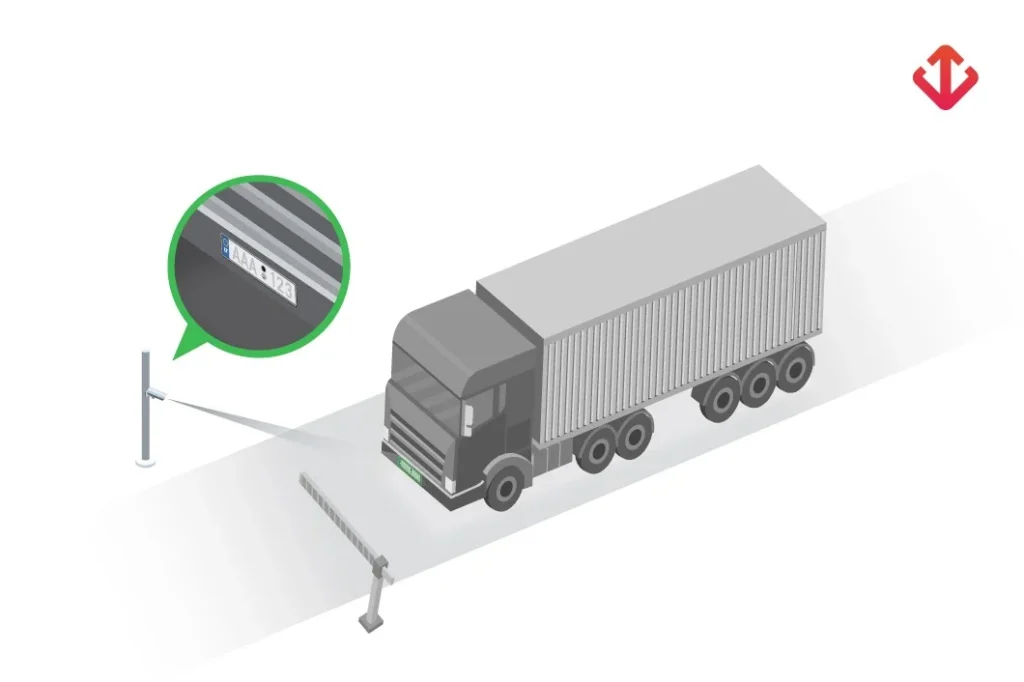

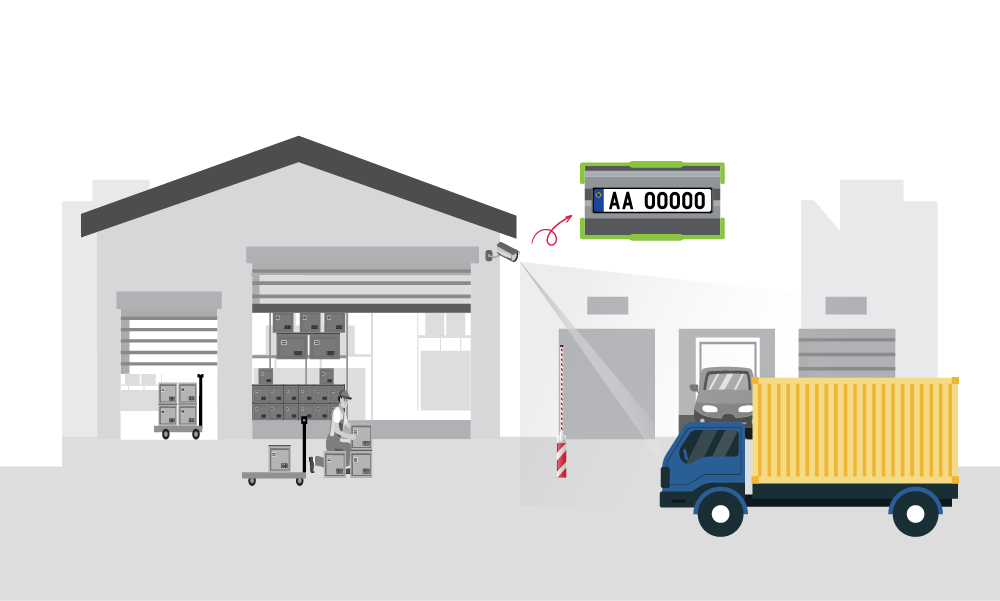

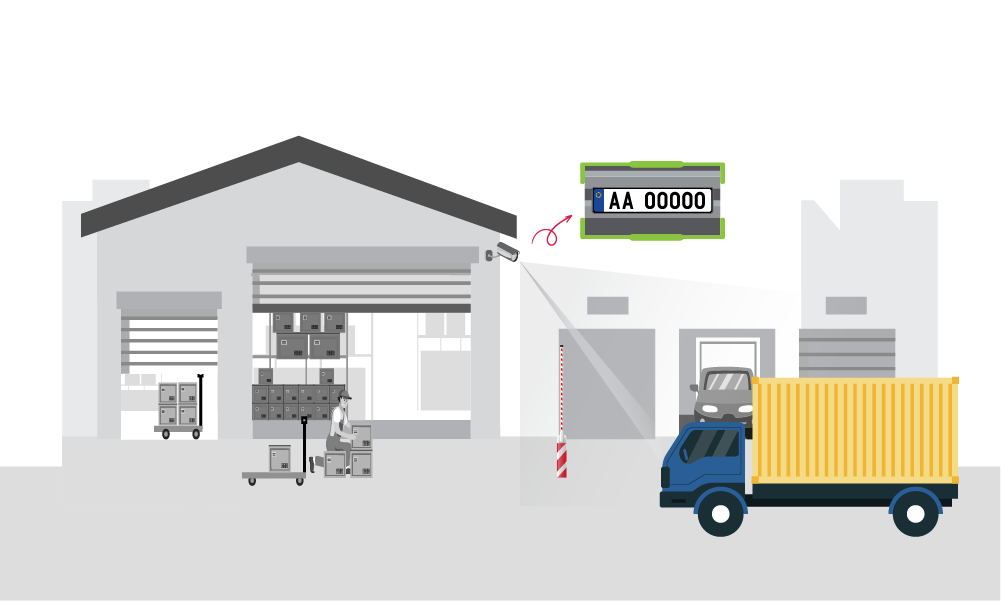

Number Plate Scanning

OCR is used for scanning the vehicle license plates at the entries of warehouses and ports. It is used to automate entry and exit logs, track delivery trucks and improve security.

Real-Time Inventory Tracking

Logistics companies can combine OCR with barcode scanners (or RFID tags) to track their inventory in real-time. As a shipment arrives or departs, OCR scans the label and updates its information in the inventory management system. It eradicates the possibility of human-led manual errors.

Warehouse Digital Twin

A warehouse digital twin gives the virtual representation of the warehouse, showing real-time data of stock, equipment and space usage. OCR can be used to feed data to the digital twin by scanning data from documents and objects. It helps the logistics managers optimize their space utilization and predict future demands.

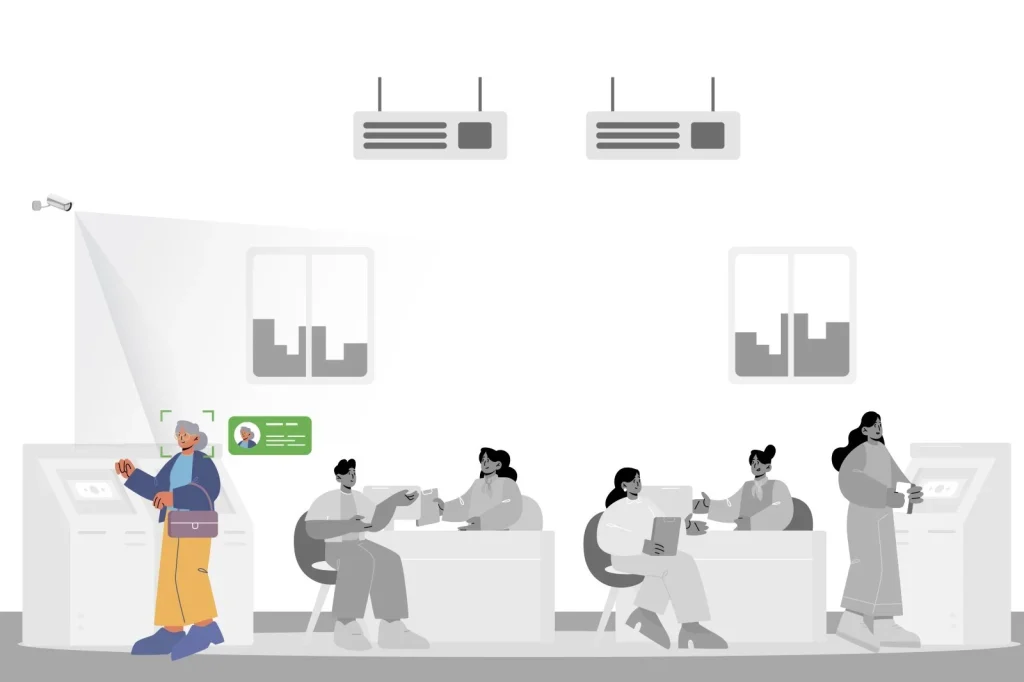

Unauthorized Vehicle Access

OCR can be used to monitor and control the access of unauthorized vehicles at the logistics hub. By scanning the license plates and comparing them with the records, the system can restrict the entry of non-registered vehicles.

Parking Twin

Just like the warehouse twin, parking twin is also a digital model which can track the movement of vehicles and check availability of parking space. The model uses OCR and IoT to ease parking management at large logistics hubs.

Streamlining Customs and Compliance Documentation

OCR can also be used at custom departments to automate the processing of legal and customs forms. It will ensure compliance and faster clearance at the borders.

Benefits of OCR in Logistics

Talking specifically about the logistics sector, integration of OCR technology gives some noteworthy benefits.

Improved efficiency

When the time-consuming manual entries processes are replaced by automation, efficiency dramatically increases. With the fast process, lead time goes down and workflow gets accelerated.

Cost savings

Automating data extraction and storage directly reduces the cost of labor. It also prevents costs associated with errors in manual entries and delays in shipment processing.

Enhanced accuracy

By eliminating the transcription errors as a result of manual processes, OCR enhances data capture accuracy. It benefits inventory management, processing, delivery schedules and makes the operations smoother.

Integration with AI and Other Technologies

OCR as a standalone technology has numerous benefits in logistics operations. Combining it with other technologies like AI unlocks a new world of possibilities.

AI and Machine Learning

The use of AI and machine learning along with OCR improves its accuracy and gives it predictive capabilities too. Learning from the previous entries, the system can analyze the extracted data to minimize errors and improve overall performance.

Cloud-Based and Mobile-Friendly Solutions

Cloud-based OCR means users can add and access data from anywhere. It allows logistic professionals to scan documents from anywhere and update the system in real-time. It makes the operations more agile and responsive.

Future Trends in OCR for Logistics

The usage of OCR is fast expanding to other industries. Businesses are exploring endless possibilities of using OCR along with other advanced technologies to create distinct use cases for them. That said, the future of OCR is poised for exciting advancements. Let’s see what the logistics sector can expect from this.

Mobile OCR

The growth of mobile technology has also helped the development of mobile-based OCR applications. Capturing images from smartphones and using it for OCR has become so easy.

Autonomous Vehicles

Equipping the self-driving trucks with OCR would mean their data collection will get automated, and their route can be optimized automatically. This would enhance freight transport by reducing human errors.

Globalization and Language Processing

With enhanced processing of multi-language documents, OCRs will facilitate smoother international transactions and compliance as per diverse regulatory requirements.

Conclusion

OCR is transforming the way logistics companies manage their documents and optimize their supply chains. It enhances efficiency, accuracy and expedites operations by automating their data entry and processing.

With the logistics industry becoming more digital by the day, the rate of OCR adoption by the companies is also on the rise. Logistics companies are incorporating OCR in their operations to stay competitive, respond swiftly to demands of the market and customers and streamline their operations.

Are you in for it too? Contact us to know how our OCR solutions can help your logistics operations.