Semiconductor fabrication plants, commonly called fabs, are some of the most complex and expensive factories ever built. Inside cleanrooms that are thousands of times cleaner than a hospital operating room, wafers of silicon are transformed into chips that power the world’s smartphones, cars, medical devices, and satellites.

Every wafer goes through hundreds of steps, lithography, deposition, etching, polishing, packaging, and at each step, there is zero tolerance for mistakes. A single defect invisible to the human eye can multiply across millions of transistors and render an entire batch of chips useless. With advanced fabs costing billions of dollars to build and wafers worth thousands each, failure is not an option.

For decades, engineers relied on human inspection, microscopes, and rule-based automation to monitor wafers. But as technology nodes have shrunk from 90nm to 7nm, 5nm, and now 3nm, and with 2nm on the horizon, the old methods are no longer enough. Patterns are too complex, tolerances are too small, and the stakes are too high.

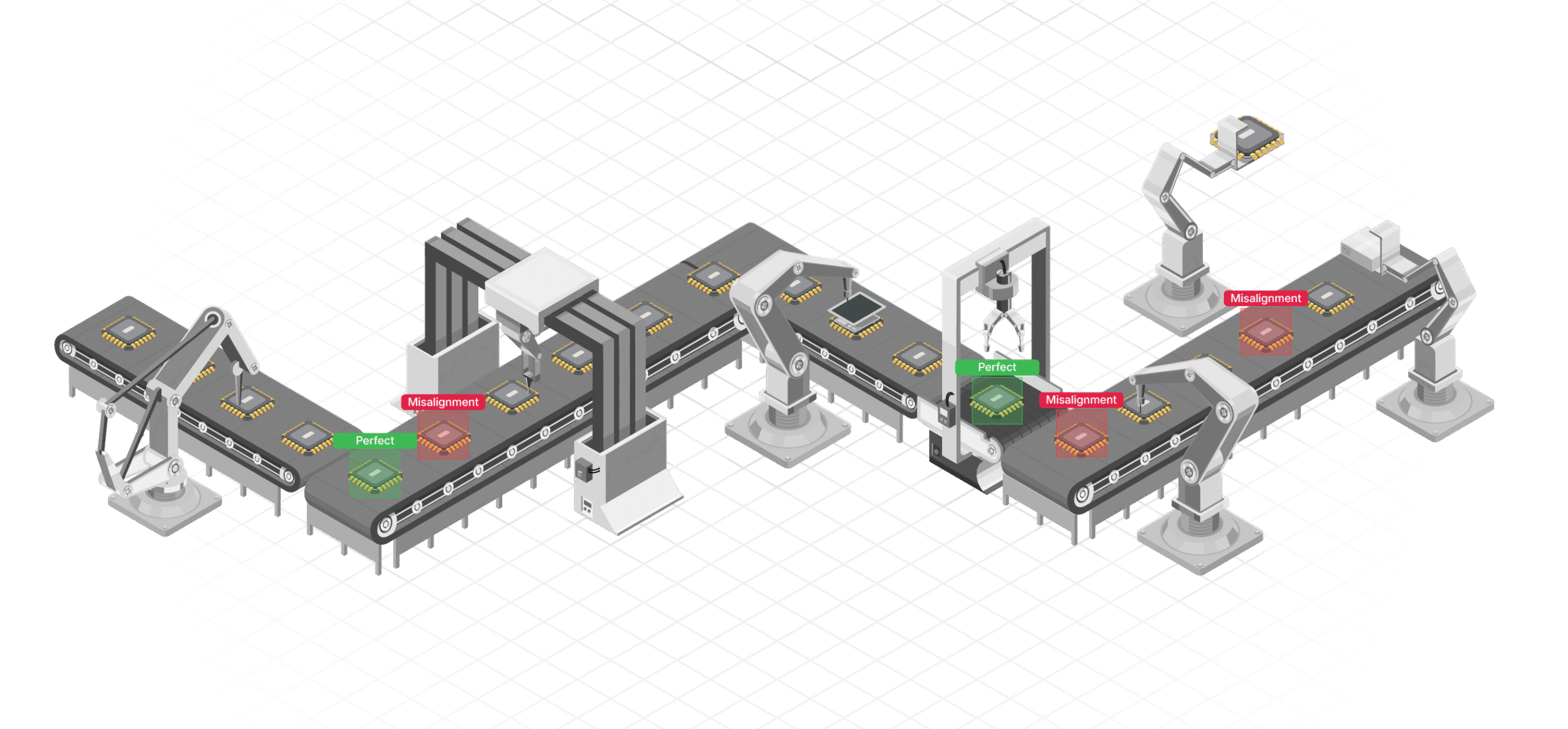

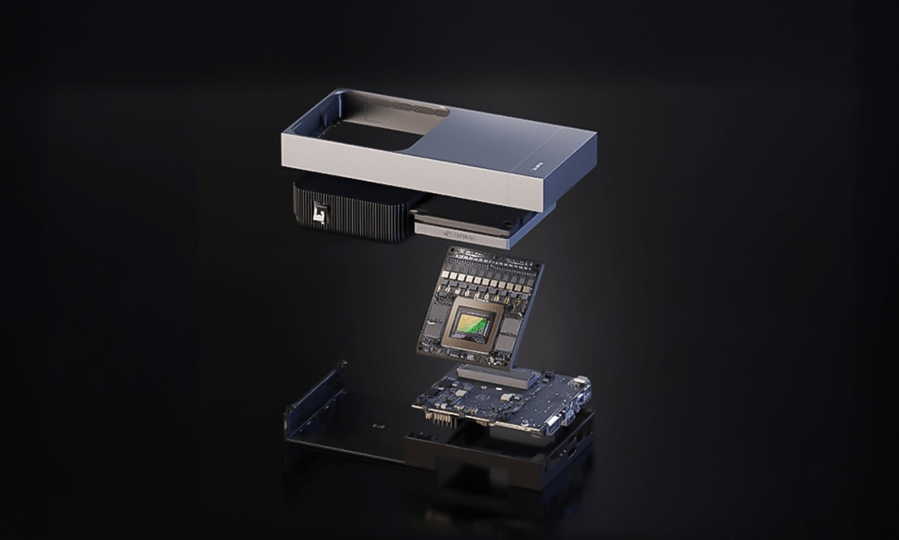

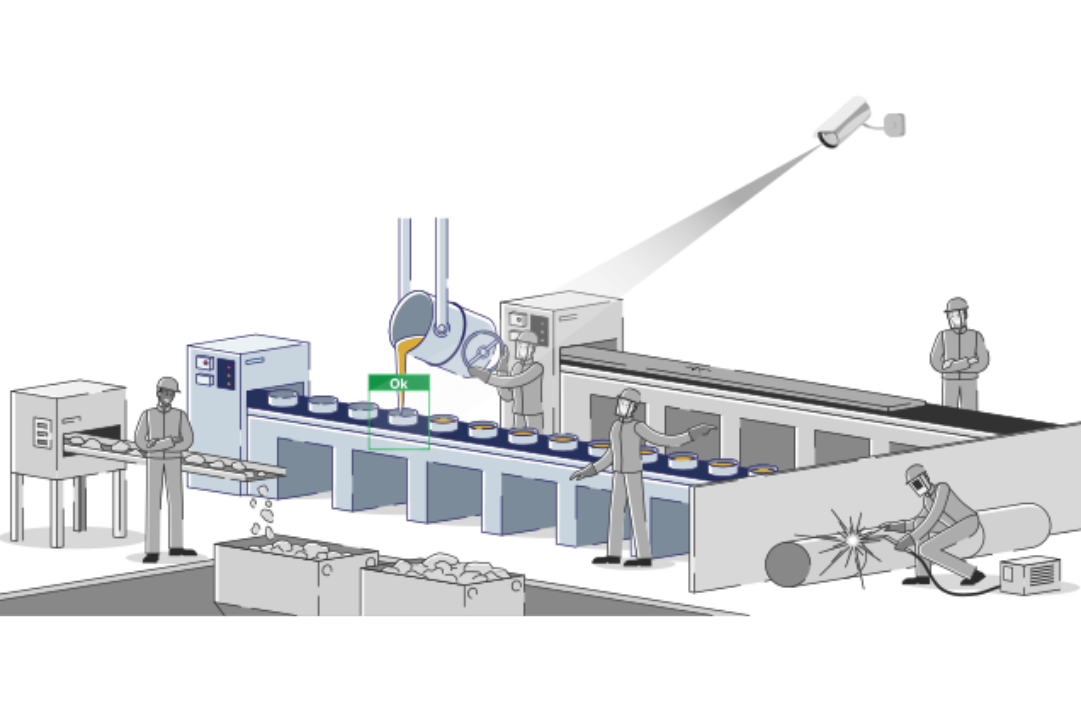

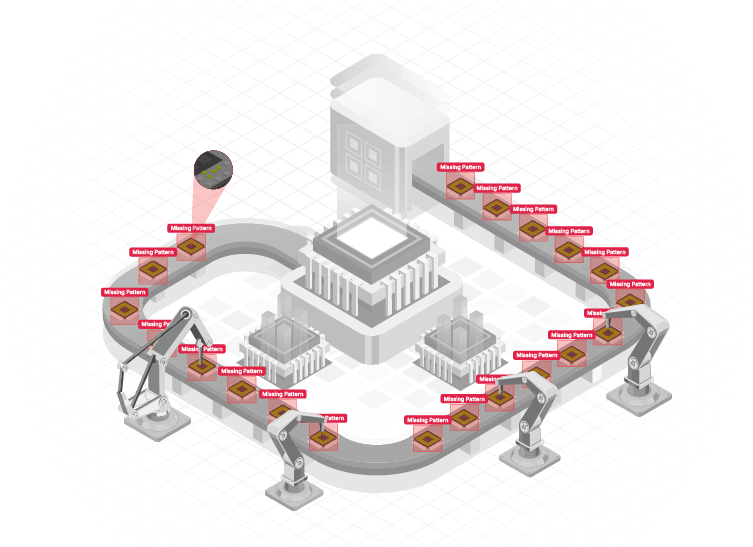

This is where computer vision in semiconductor manufacturing is changing the game. By combining ultra-high-resolution cameras with deep learning and automation, computer vision has become the new eyes of the fab. It enables real-time monitoring, faster decision-making, and higher accuracy than humans or legacy tools can achieve. From AI wafer inspection and overlay accuracy to CMP monitoring and packaging validation, vision based inspection is now at the heart of semiconductor automation.

Together, these technologies are giving rise to a new generation of smart fabs, factories that are not only faster and cleaner but also intelligent and adaptive.

Why Precision Matters in Semiconductor Manufacturing

To understand why fabs are embracing computer vision, we need to appreciate just how unforgiving semiconductor manufacturing is.

Each chip contains billions of transistors packed into a space smaller than a fingernail. A single defect, such as a scratch, a particle of dust, or a misaligned pattern, can cause a chip to fail. And because wafers are processed in lots, one defect can spread across hundreds of chips, costing millions of dollars in losses.

Photomasks, for example, act as the stencils for circuit patterns. If a photomask has a defect, that flaw is repeated across every wafer it prints. Similarly, if CMP polishing leaves a wafer slightly uneven, every subsequent layer is affected. If plasma etching goes too deep or too shallow, entire circuits may be ruined.

In short, precision is everything. And the smaller the node, the less room there is for error. This is why fabs are now investing heavily in semiconductor fabrication AI, to ensure that even the tiniest issues are caught and corrected before they cause large-scale yield loss.

Where Computer Vision Makes an Impact

Computer vision is no longer limited to a single inspection step. It is now present across almost every stage of semiconductor manufacturing. Let’s explore the key areas where it makes the biggest difference.

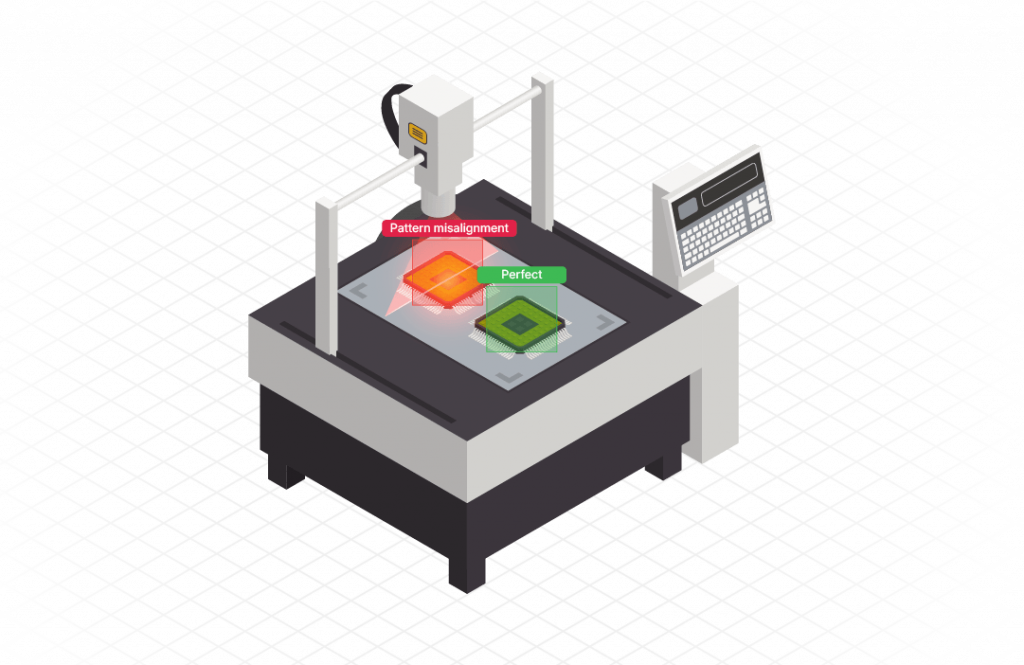

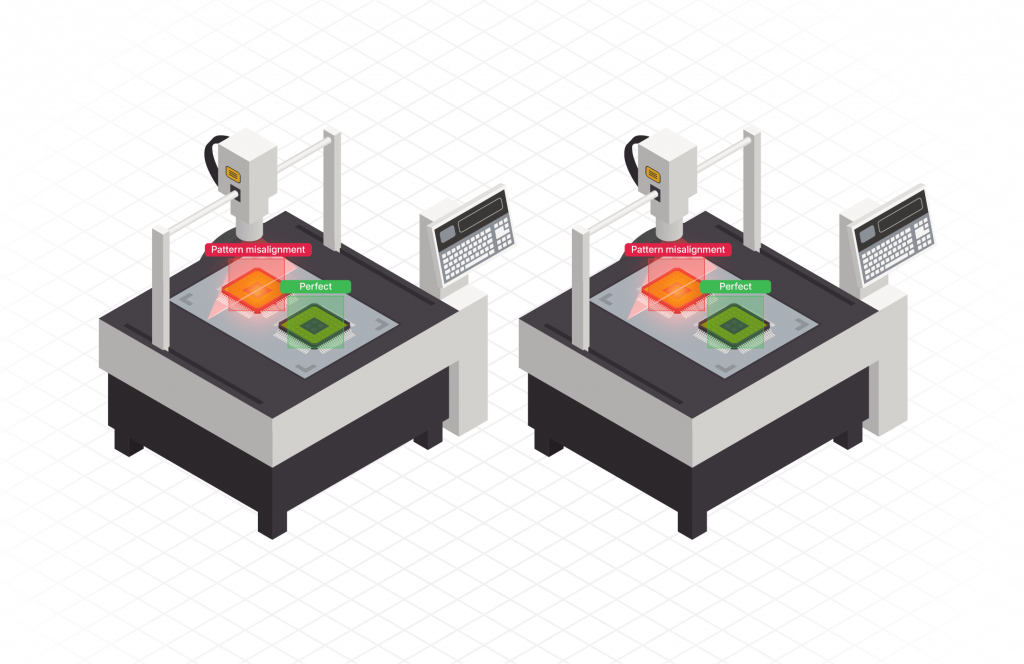

1. Photomask Defect Inspection

Photomasks are the master blueprints for chips. Traditional inspections often missed defects at the sub-30nm scale. Now, AI-driven vision systems can scan masks at extreme resolution, catching defects like pinholes, scratches, or contamination before they spread to wafers. This improves yield and prevents costly rework.

2. Alignment and Overlay Accuracy

As layers are stacked on top of one another, even a nanometer misalignment can cause electrical failures. Vision systems constantly monitor overlay accuracy, ensuring patterns line up perfectly. This is critical as fabs move to EUV (Extreme Ultraviolet) lithography, where tolerances are razor-thin.

3. CMP (Chemical Mechanical Planarization) Monitoring

CMP polishes wafers flat between layers, but it can also introduce dishing, erosion, and scratches. Vision systems analyze wafer surfaces post-CMP, detecting non-uniformity in real-time. This prevents defects from compounding across dozens of layers.

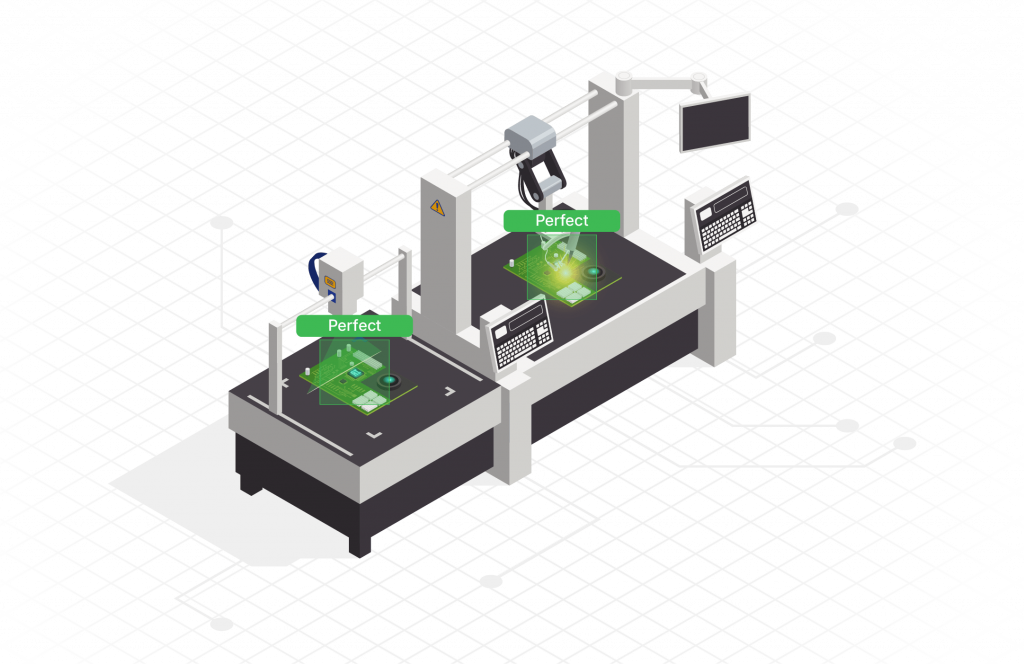

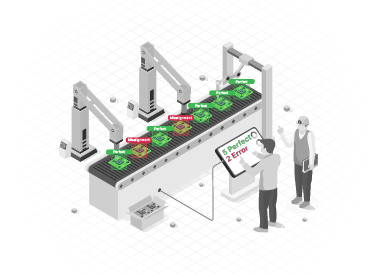

4. AOI (Automated Optical Inspection) for PCBs and Modules

Once wafers are processed into modules or PCBs, vision systems check for open circuits, soldering faults, and missing components. AI wafer inspection at this stage ensures that packaging errors don’t undo the precision of earlier steps.

5. Plasma Etching Endpoint Detection

Etching defines the fine features of a chip, but stopping too early or too late can ruin circuits. Computer vision systems analyze plasma glow patterns in real time, ensuring etching ends exactly when it should.

6. Resist Coating and Film Uniformity

Photoresist coating must be perfectly even. Vision-based inspection detects film thickness variations or surface contamination during coating, ensuring lithography accuracy.

7. Packaging and Assembly Validation

In advanced packaging like Package-on-Package (PoP), vision systems ensure vertical alignment and connection integrity before reflow. This prevents latent defects that may only appear later in use.

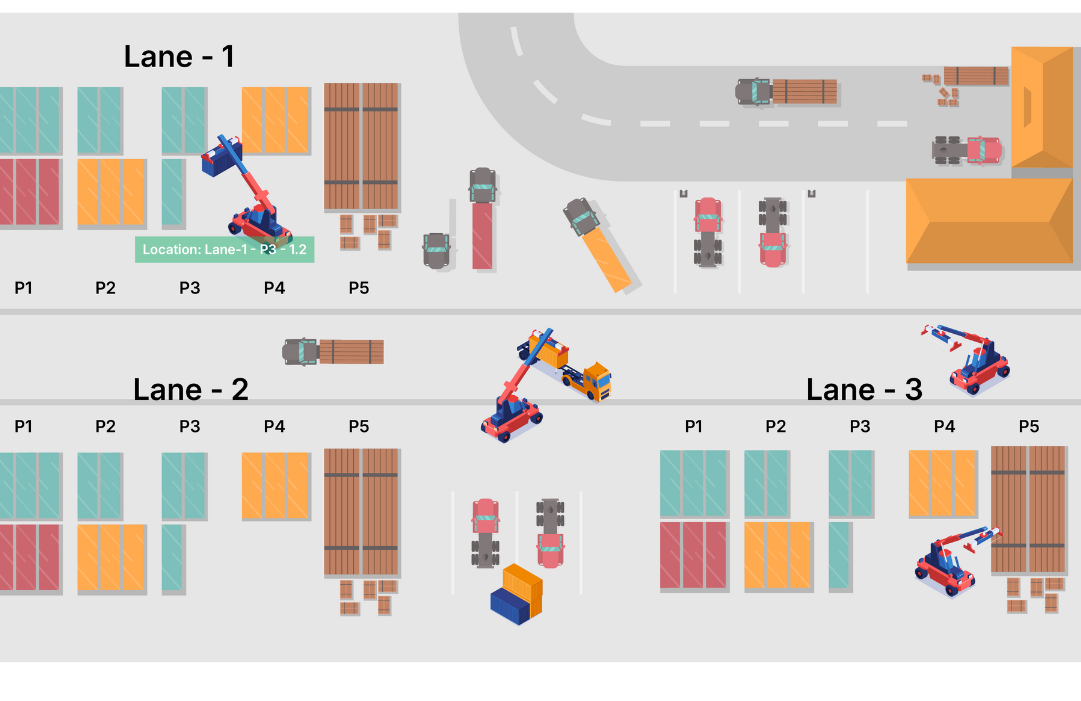

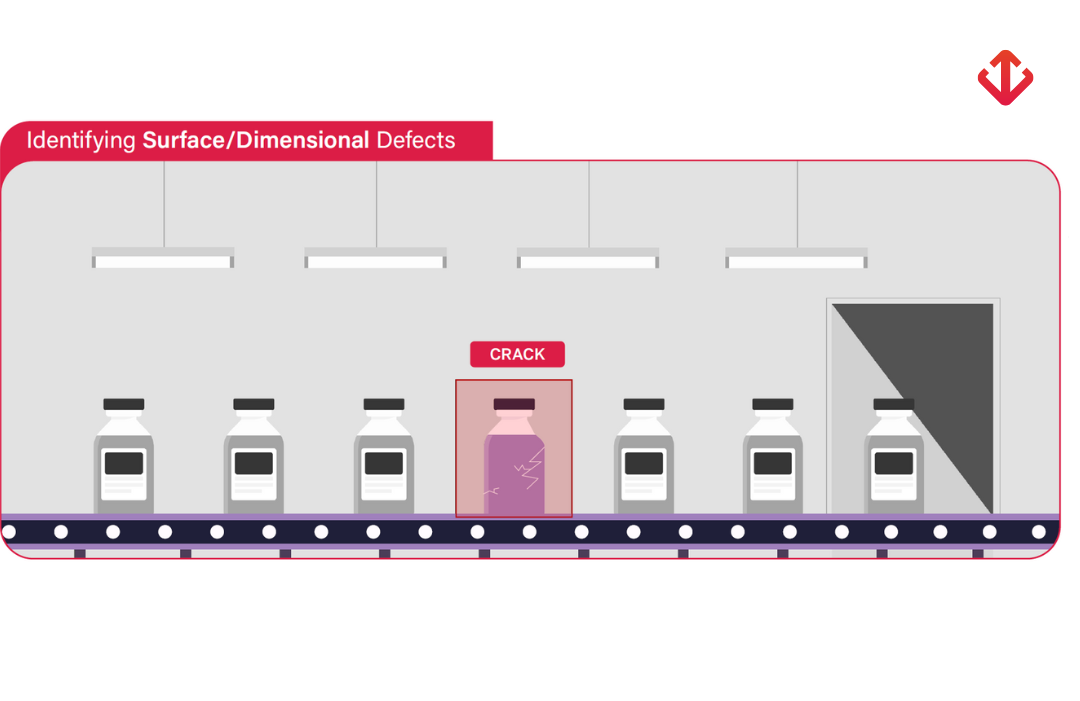

8. Defect Classification and Sorting

Instead of just flagging problems, modern vision systems categorize them, scratches, voids, pits, bubbles, so fabs can find root causes faster. This accelerates problem-solving and improves long-term yields.

Together, these use cases show how vision systems act as the silent guardians of fabs, watching every process, every wafer, every layer.

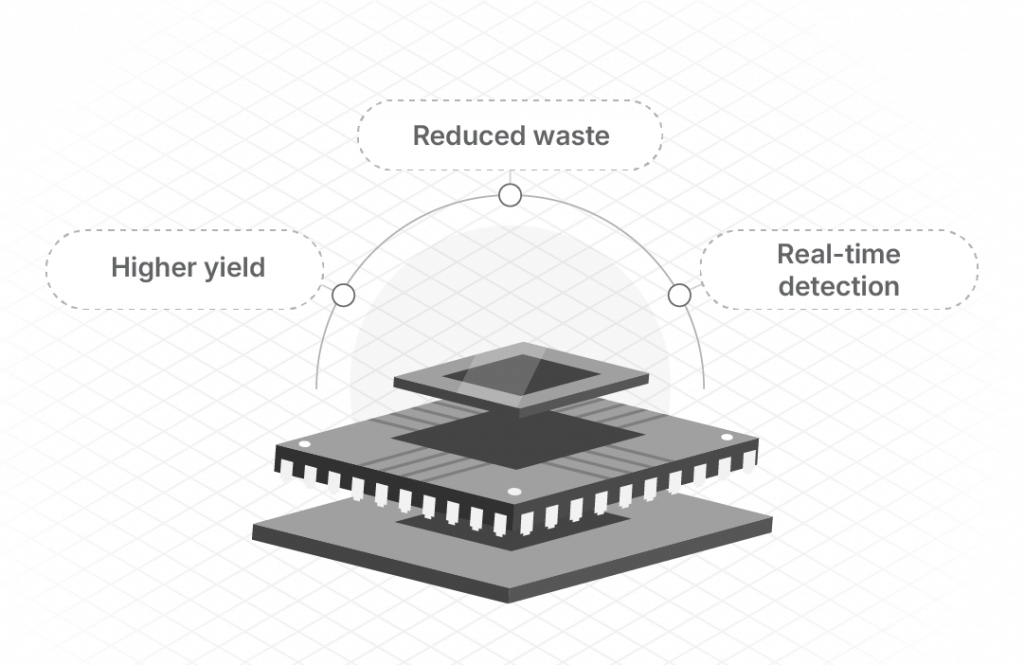

The Benefits of Computer Vision in Fabs

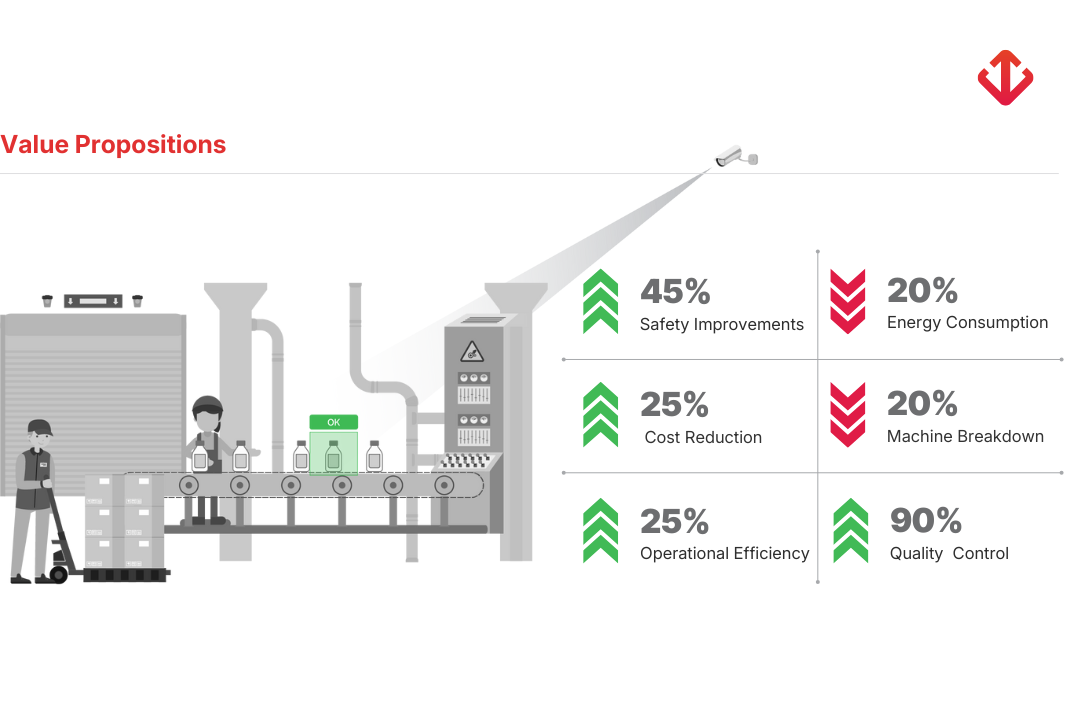

The impact of computer vision is more than just catching defects. It changes the economics and efficiency of semiconductor manufacturing.

- Nanometer Accuracy: Detects defects invisible to traditional tools.

- Real-Time Monitoring: Prevents cascading failures before they spread.

- Higher Yield: More wafers pass final tests, boosting profitability.

- Consistency: Removes human subjectivity and fatigue.

- Cost Savings: Avoids multi-million-dollar losses per defect lot.

- Scalability: Adapts to 28nm, 7nm, 3nm, and future 2nm nodes without reprogramming.

One report suggests that fabs using vision based inspection and semiconductor fabrication AI have seen yield improvements of 20–30%, translating to hundreds of millions of dollars in savings each year.

Real-World Examples & Industry Trends

The world’s leading fabs are already adopting these technologies.

- TSMC uses AI inspection to manage the complexities of EUV lithography.

- Samsung has integrated AI monitoring in its 3nm Gate-All-Around processes.

- Intel has deployed deep learning for faster defect classification, cutting manual review times significantly.

In one case study, a fab that piloted AI-based CMP monitoring reported a 25% reduction in defect escapes and a 40% faster inspection cycle time. Another fab saw false positives drop by over 30%, freeing engineers to focus on real problems.

The analogy is clear: traditional inspection is like using a magnifying glass; AI-driven computer vision is like running an MRI scan. It sees deeper, faster, and with more context.

Challenges and Considerations

Adopting computer vision across fabs isn’t without hurdles.

- Data Volume: High-resolution imaging produces massive data streams. Processing them requires edge computing near tools, often combined with cloud analytics.

- Integration: AI outputs must connect smoothly with lithography machines, MES systems, and yield management platforms.

- Security: Wafer designs and defect libraries are highly valuable IP. Systems must ensure confidentiality.

- Continuous Learning: As fabs introduce new materials and nodes, AI models need retraining.

Despite these challenges, the momentum is clear. The benefits far outweigh the barriers, and fabs are finding ways to integrate vision systems at scale.

The Future of Computer Vision in Semiconductor Fabs

The future lies in smart fabs, factories where vision systems not only detect defects but also correct processes automatically.

- Closed-Loop Manufacturing: Vision systems detect an issue and adjust polishing, etching, or coating in real time.

- Predictive Maintenance: AI predicts when tools need servicing before defects occur.

- 3D ICs and Chiplets: As designs move toward stacked chips, vision will be critical for ensuring perfect alignment.

- Zero-Defect Ambition: With continuous monitoring, fabs are moving toward defect-free manufacturing.

In short, computer vision is turning fabs from reactive factories into intelligent, semiconductor automation ecosystems.

WebOccult’s Role in Fab Transformation

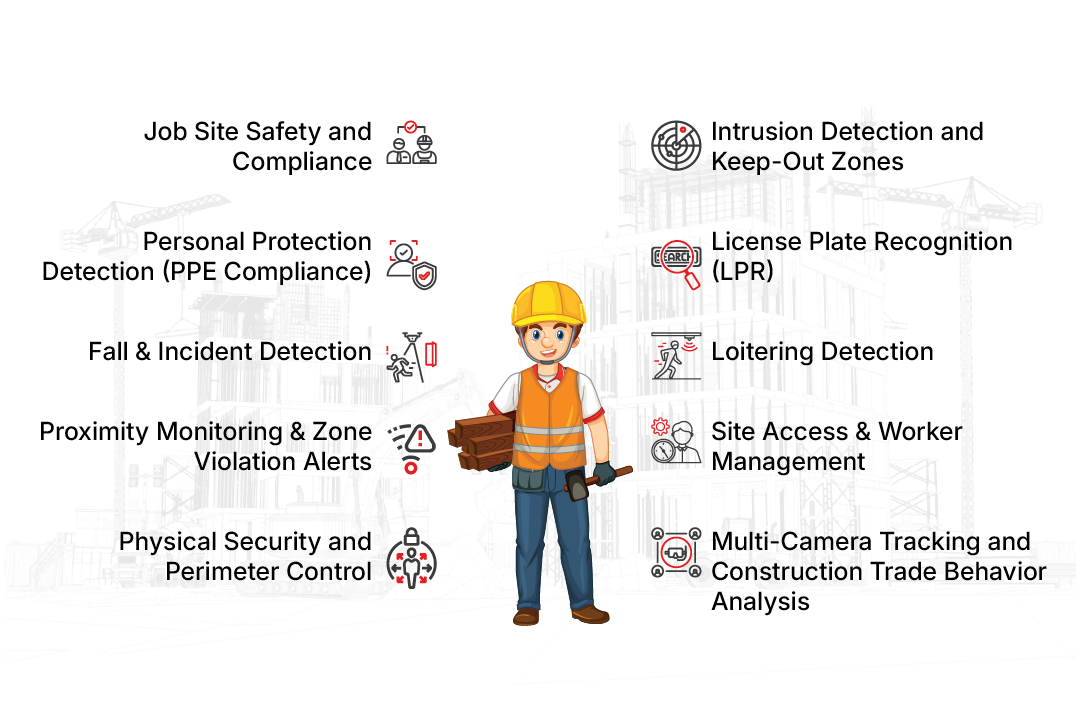

At WebOccult, we understand that semiconductor fabs are under pressure like never before, shrinking nodes, tighter tolerances, higher costs, and massive demand. Our AI Vision solutions are built to help fabs navigate this challenge.

- We provide AI wafer inspection tools that catch the smallest defects.

- Our systems are designed for real-time, vision based inspection, ensuring immediate feedback.

- We build platforms that integrate seamlessly into fab workflows, supporting semiconductor automation without disruption.

By combining expertise in computer vision in semiconductor manufacturing with deep industry knowledge, WebOccult delivers not just technology but a path to higher yield, lower costs, and smarter fabs.

Conclusion

The semiconductor industry has always balanced ambition and precision. As ambition drives us to smaller, faster, more powerful chips, precision becomes more unforgiving. At this level, a dust particle can be a villain, a scratch can be a disaster, and a single defect can cost millions.

Computer vision has become the watchtower of fabs. It ensures that defects are caught early, surfaces remain flat, patterns align perfectly, and packaging is precise. It turns fabs into smart fabs, intelligent, adaptive, and resilient.

In the race to advance Moore’s Law, computer vision in semiconductor manufacturing is not just a tool. It is the shield protecting yields, the compass guiding defect detection in chips, and the foundation of semiconductor automation.

At WebOccult, we are proud to help fabs take this leap. With AI-driven vision, we help manufacturers move closer to defect-free production, ensuring that every chip, every wafer, and every layer meets the standards of the future.