At midnight, a high value shipment enters a regional logistics hub.

By morning, the factory waited for those parts to halt production.

The system shows the shipment as “received.”

The yard team insists it was unloaded.

The transporter says it left in perfect condition.

No one is lying. No one can prove anything either.

This is how blind spots quietly drain money, time and trust. And why visual recordkeeping is necessary.

Blind Spots in Supply Chain Tracking

Blind spots rarely show up as a single failure. They ripple through operations and quietly inflate costs. Production waits for parts that are “somewhere.” Customer commitments get pushed. Teams get stuck reconciling data for hours. And the actual movement of goods slows down.

With time, supply chain visibility fades. Daily work becomes reactive instead of planned.

Common outcomes include:

- Delayed production due to unverified arrivals

- Disputes between vendors and transporters and warehouses

- Increased claims without clear proof

- Higher exposure to operational and compliance risks

This is where supply chain risk management begins to break down.

Tracking Methods that do not Work anymore

Paper logs, spreadsheets and ERP updates depend on people. They only work if someone remembers to update them. When things move quickly, even small delays matter. They create gaps between actual events and the records that follow.

Advanced systems are not enough on their own. Visibility breaks down with delayed or missing data. Subjective reporting widens the gap further.

What’s missing is not technology. It is a visibility you can trust.

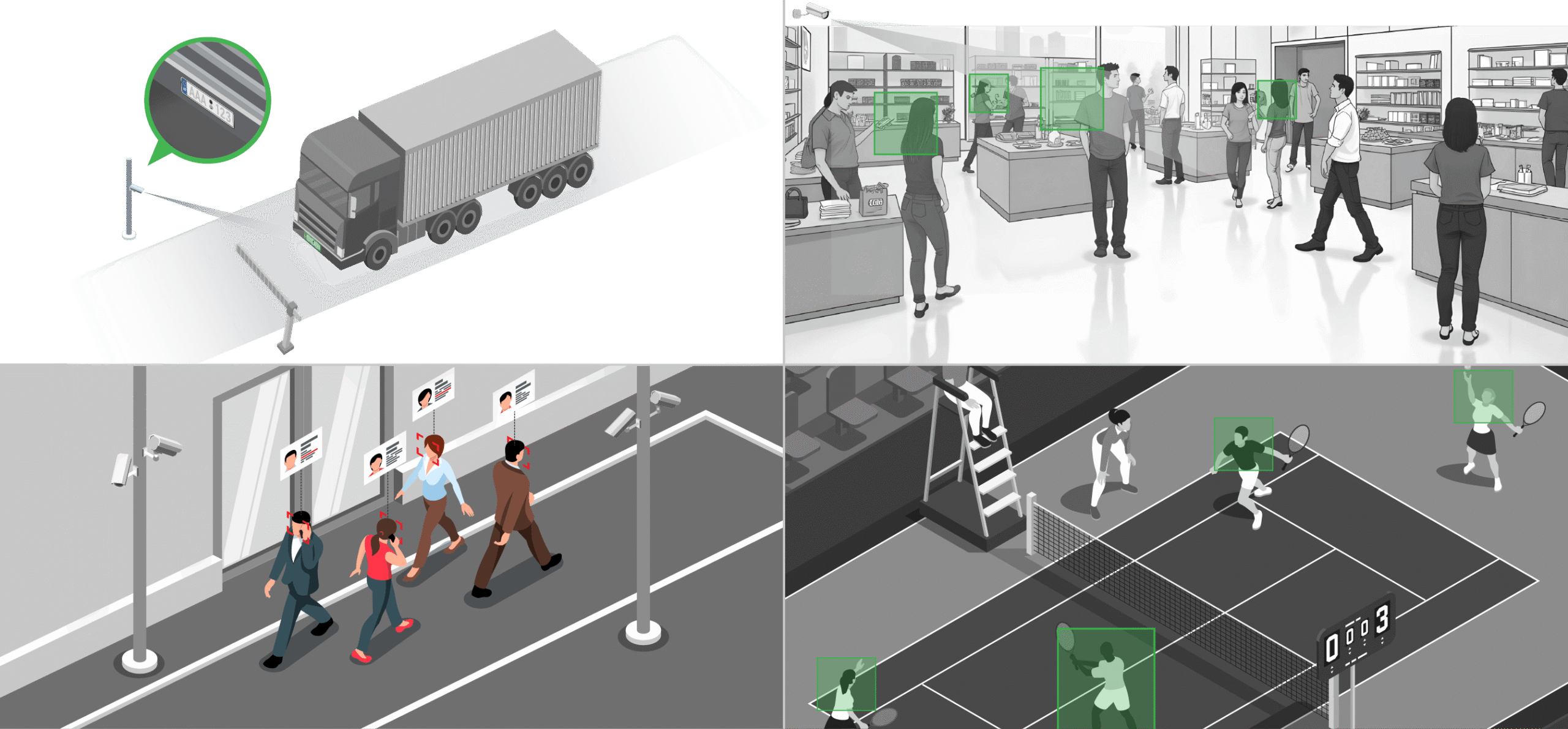

Evidence over Assumptions

Visual recordkeeping uses cameras and vision systems. They capture physical events as they happen. No more waiting for manual entries. The system records visual evidence instantly, with time and context.

Visual recordkeeping builds reliable documentation. Movements are supported by evidence instead of guesswork. Events are logged at a single time. And can be revisited whenever required.

A Supply Chain Story from the Field

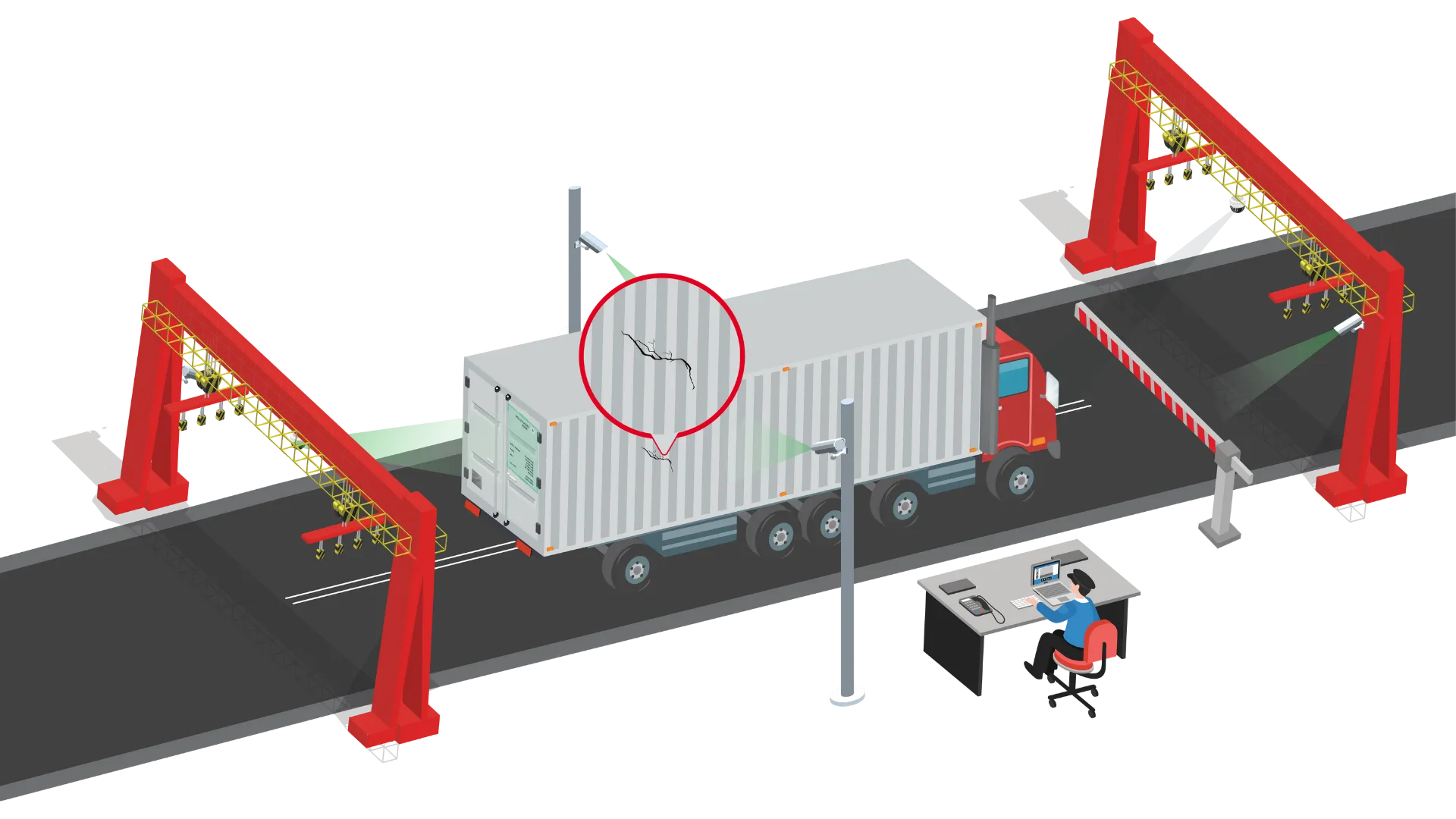

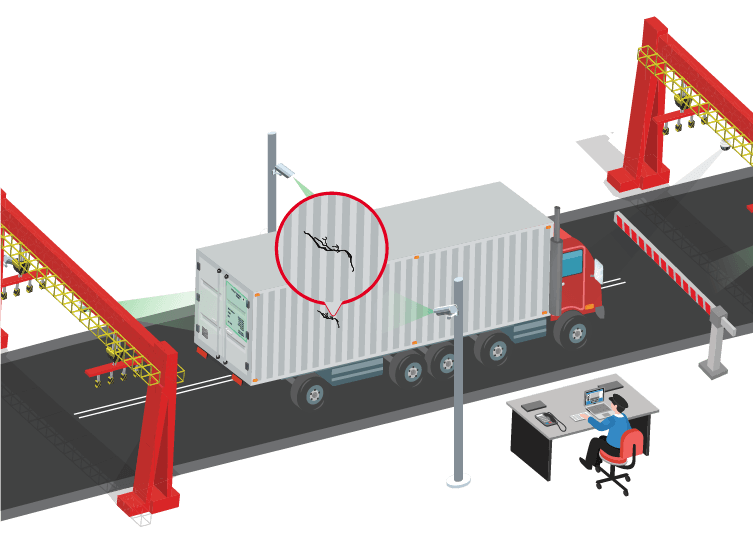

A consumer electronics distributor handling thousands of inbound containers each month struggled with recurring damage claims. Containers were logged as “received.” But damage was often discovered during unloading.

After implementing vision-based recording at entry points, every container’s condition was visually captured on arrival.

Within weeks:

- Disputes reduced sharply

- Claims were resolved faster

- Accountability became clear

This kind of shipment tracking and verification changed conversations from “who’s at fault” to “here’s what happened.”

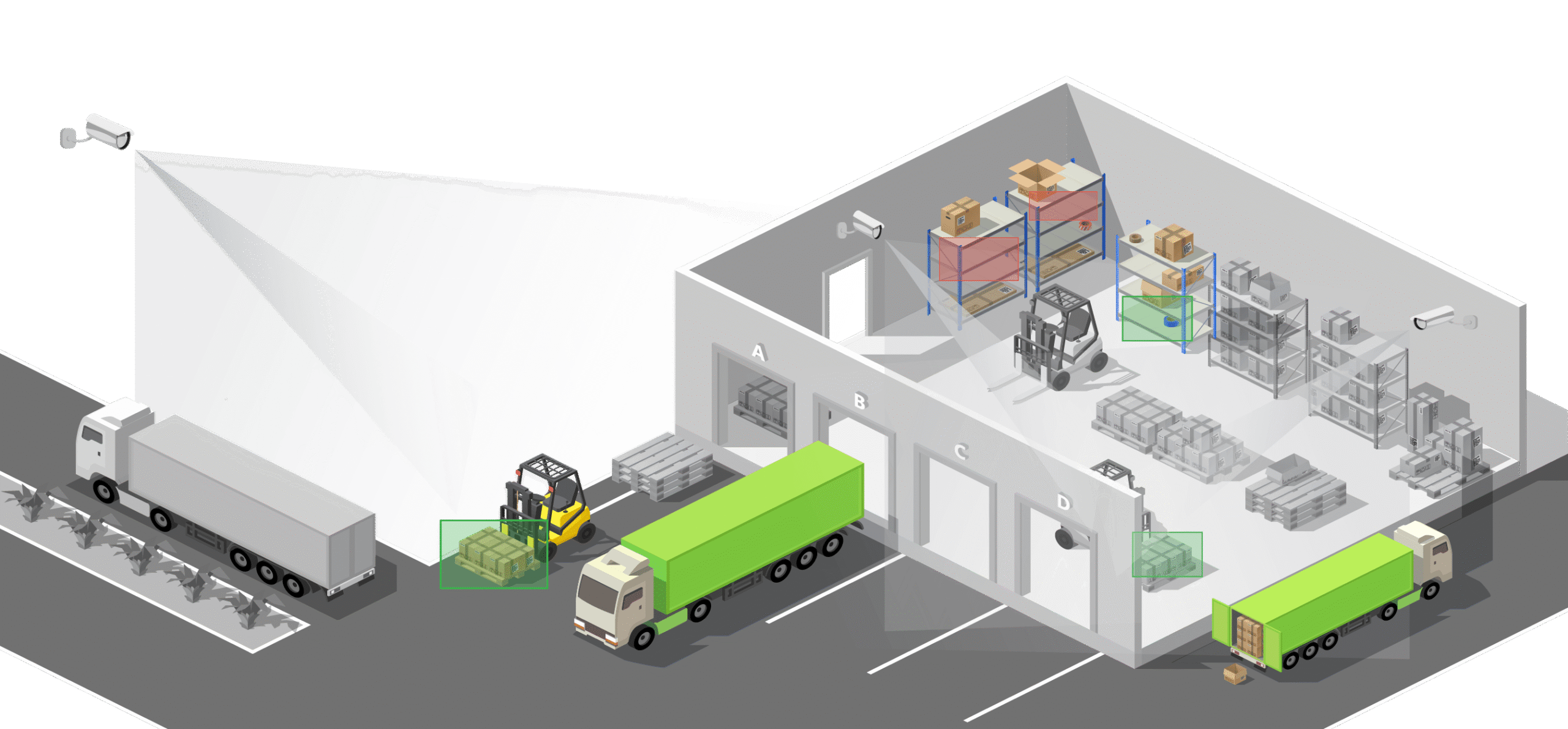

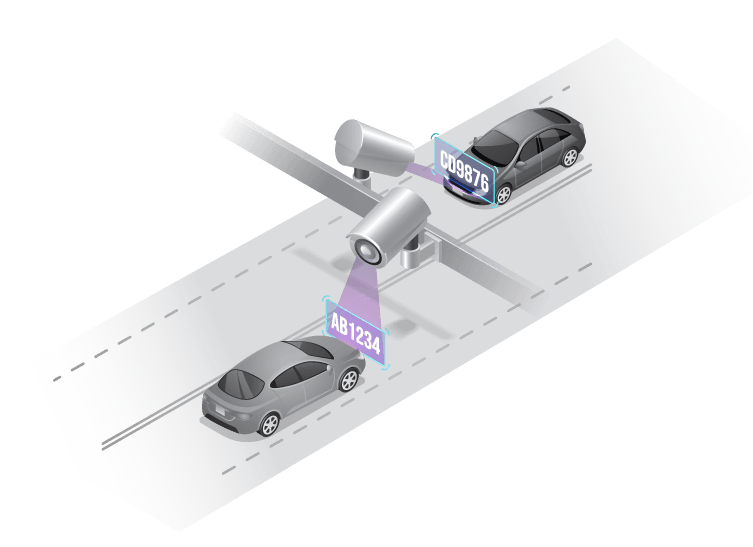

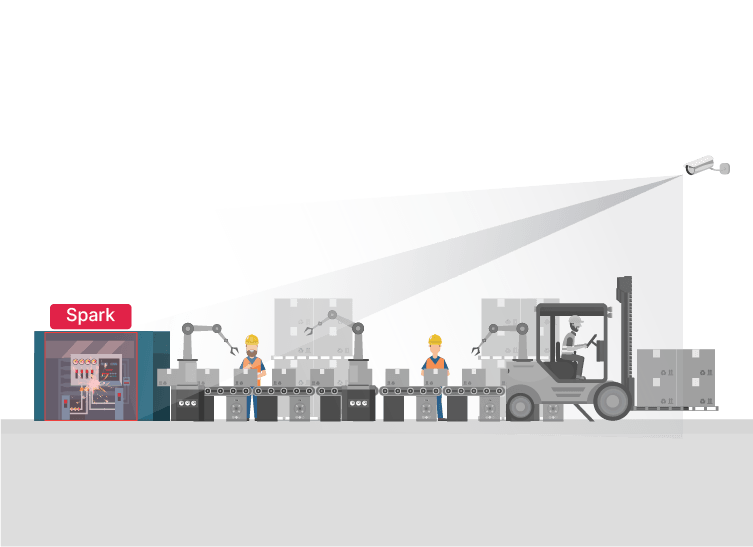

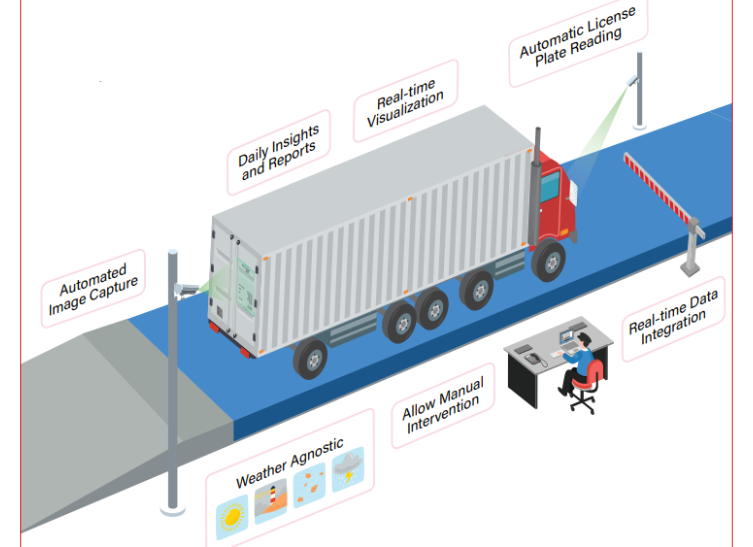

Seeing what happens from Entry to Exit

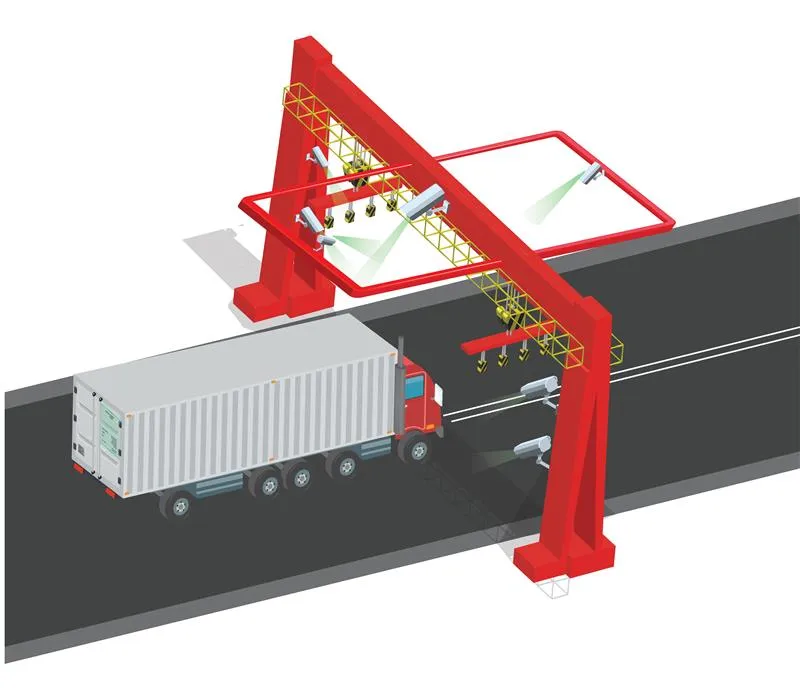

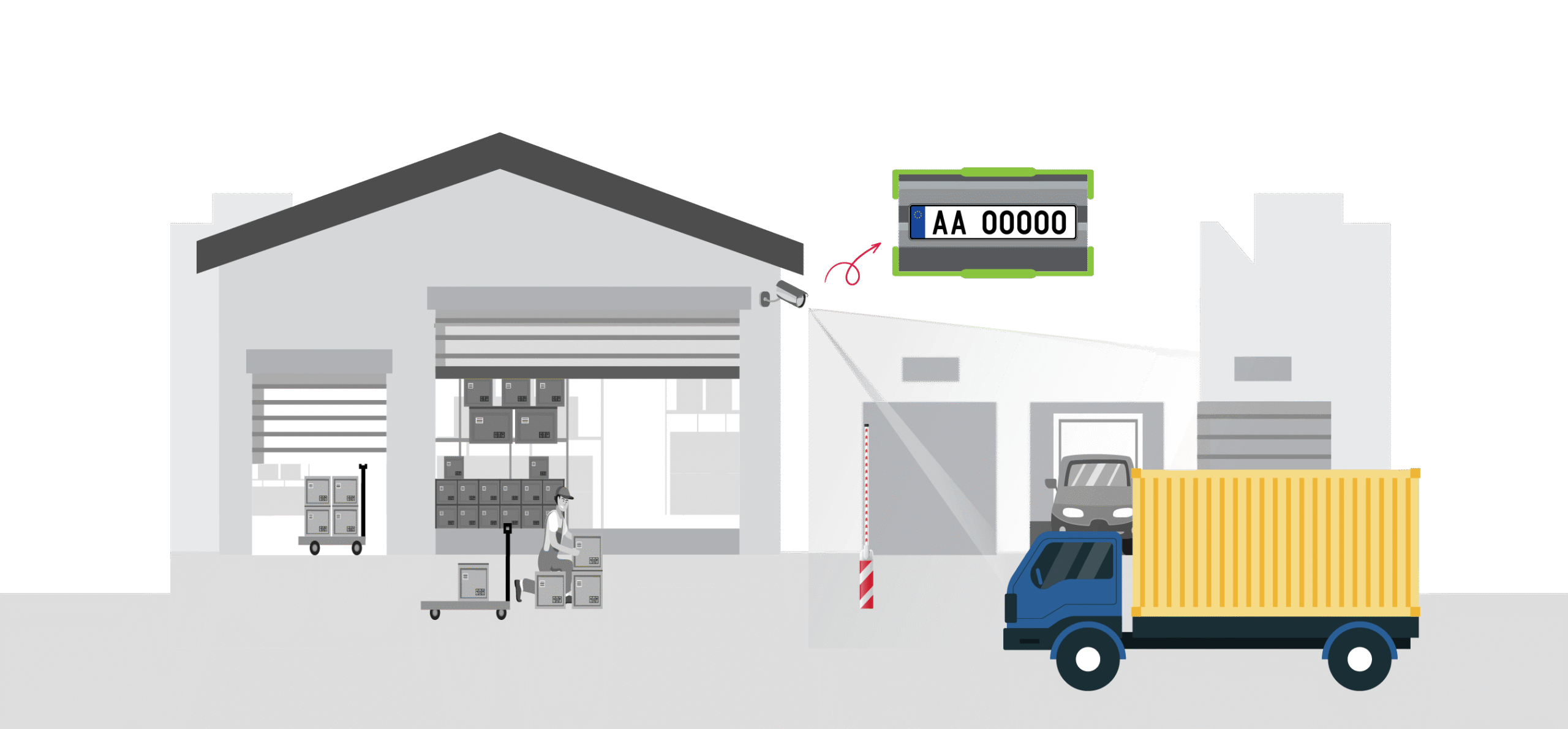

Visual systems monitor gates and yards. Each container’s number, seal and condition are captured instantly. This strengthens logistics visibility solutions by removing manual dependency.

Key benefits include:

- Accurate gate-in and gate-out records

- Clear turnaround time tracking

- Verified container movements without delay

Each event leaves behind visual proof instead of a checkbox.

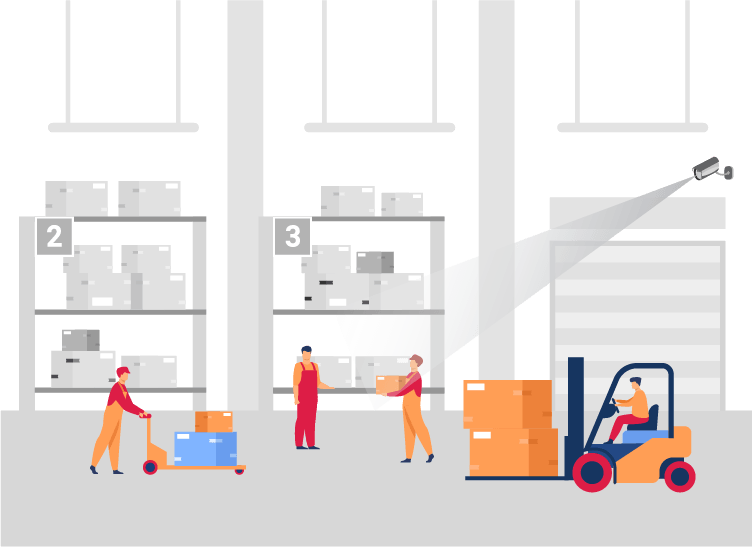

Warehousing without Inventory Surprises

Inside warehouses, blind spots often come from delayed inventory updates. Movements are tracked instantly through visual recordkeeping. Arrival and movement are documented with proof. Exits are captured at the moment they happen.

Visual proof builds confidence in inventory. It sharpens planning and forecasting. And it removes the need for emergency recounts or production stoppages.

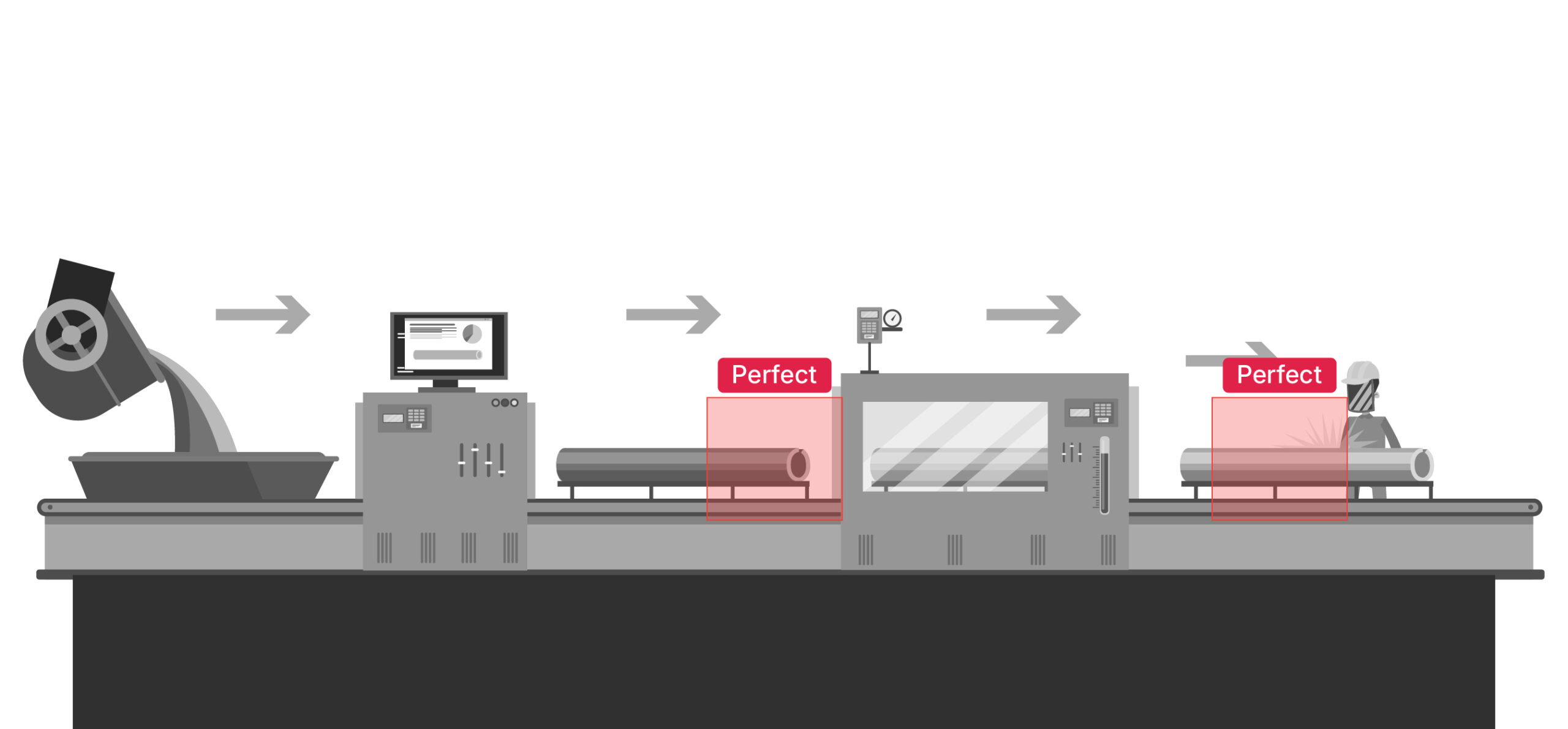

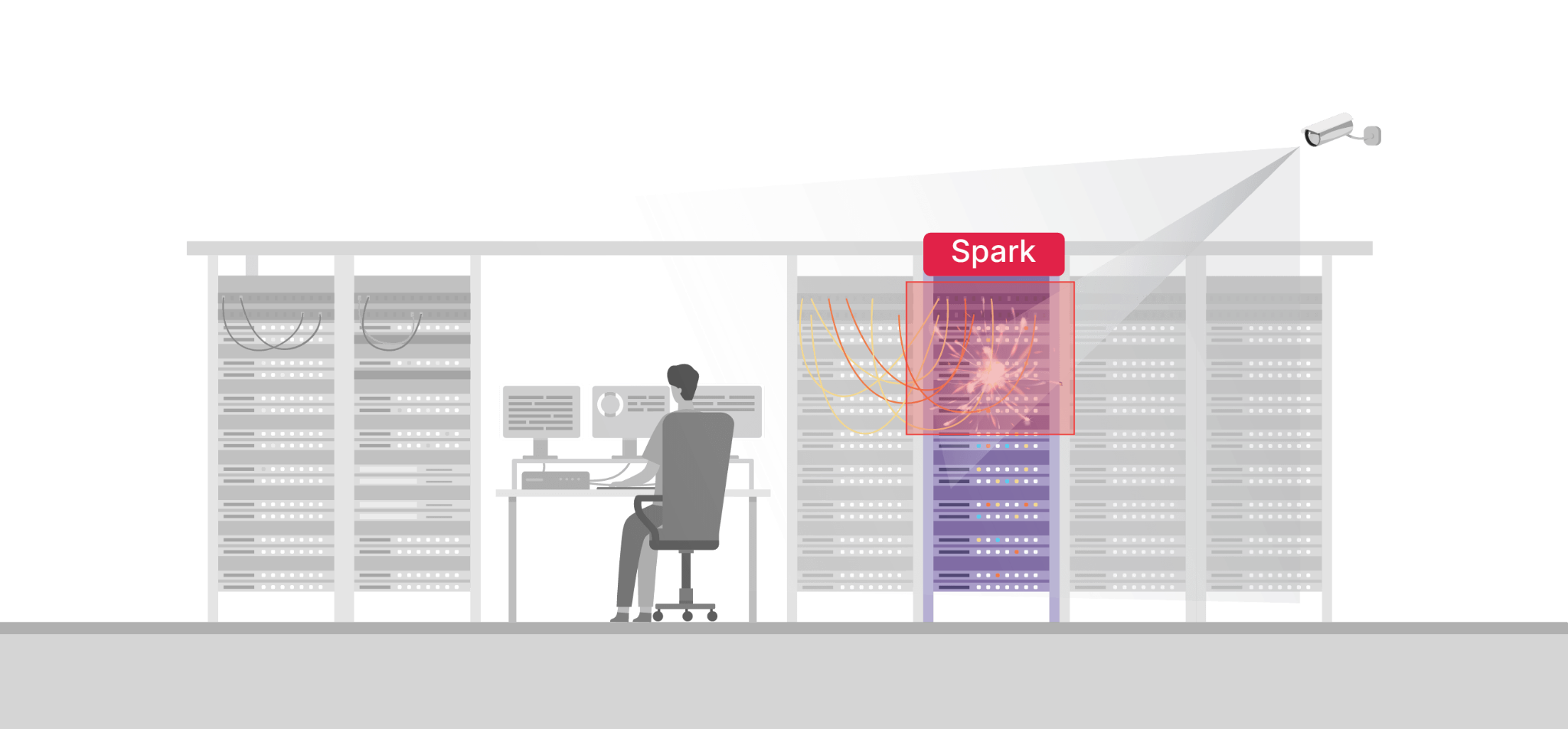

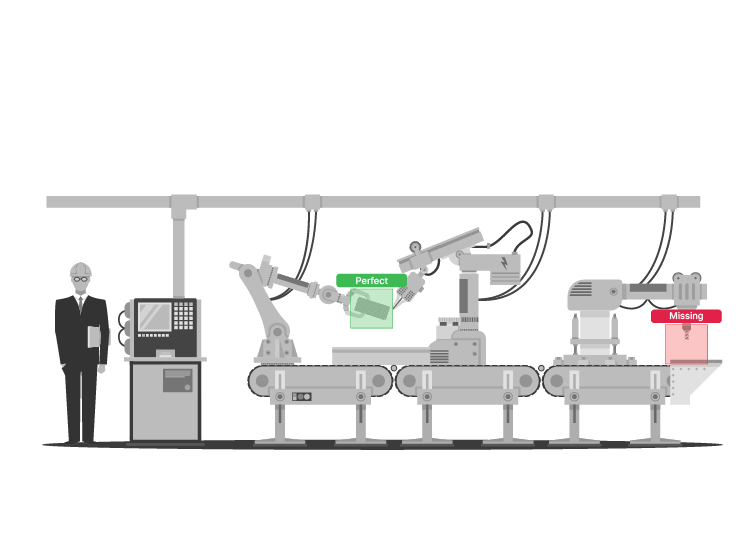

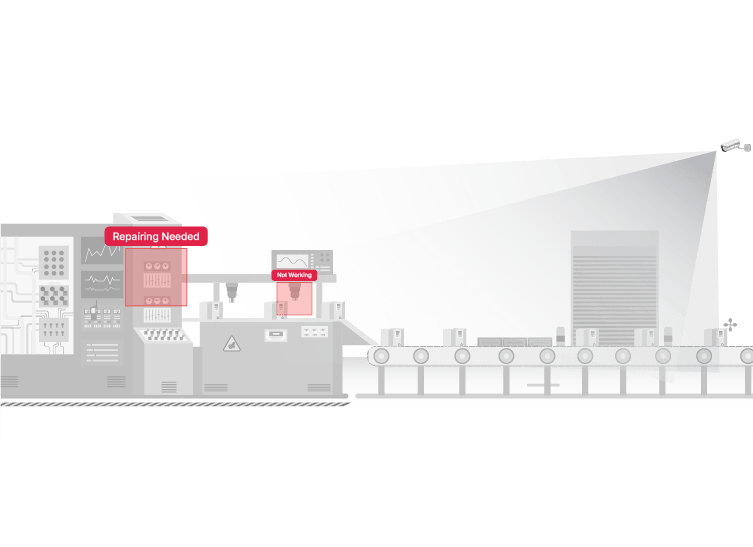

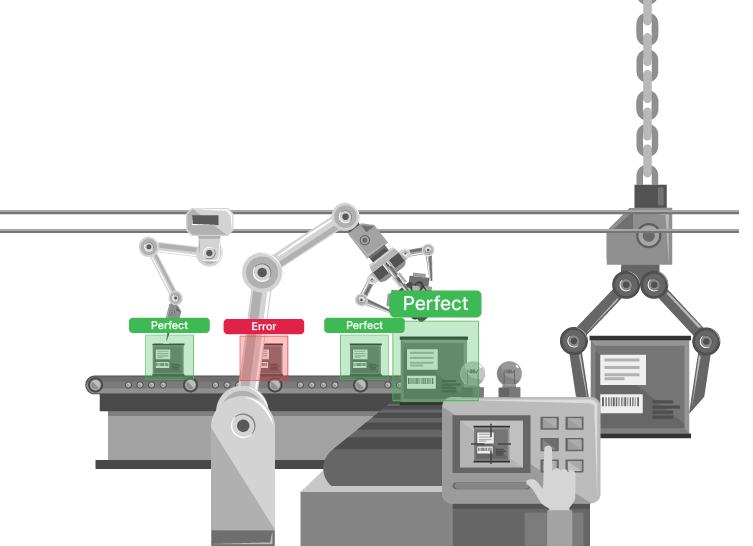

Real‑Time Visibility on the Factory Floor

In manufacturing environments, this level of visibility is a must-have. Modern plants rely on visual recordkeeping built for manufacturing operations. It is to maintain quality, uptime and safety in real time.

On the factory floor, even small delays or defects have large consequences. Visual systems monitor production flow continuously. Bottlenecks or stoppages or quality deviations occur. They are captured by visual systems. And become visible the moment they happen.

Real‑time visibility drives quicker decisions. Teams do not have to wait for end‑of‑shift reports. The result is stronger and more reliable operations.

Proof of Condition Documentation changes Everything

Damage disputes thrive in the absence of evidence. Visual systems document condition at each stage. They capture arrivals, internal moves and dispatches in real time.

Instead of opinions, teams rely on images and timestamps. Claims close faster. Trust improves across partners.

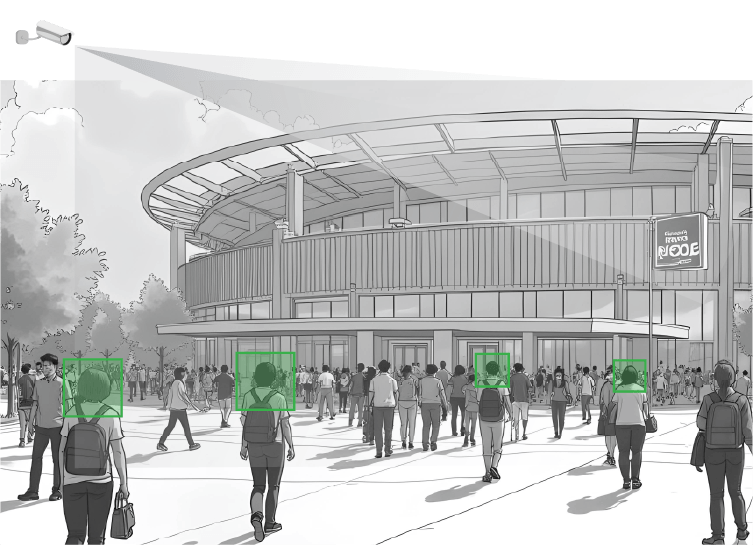

One Continuous Chain of Truth

Logistics, warehousing and manufacturing align on one visual record. That alignment removes blind spots. The result is clear and trusted visibility everywhere. Data flows as a single narrative and not fragmented reports.

This is what end-to-end supply chain visibility looks like.

Why Transparency cannot Wait

Supply chains face tighter deadlines and tougher compliance. There is zero tolerance for errors. Manual systems simply cannot keep pace.

Visual recordkeeping strengthens supply chain transparency while reducing risk and operational friction. Teams stop chasing explanations and start preventing issues.

When nothing is Invisible, everything Works

Supply chains do not fail because people do not care. They fail because too much happens without being seen.

Visual recordkeeping turns physical movement into reliable knowledge. Every shipment, every container, every step is accounted for.

When nothing is invisible, everything works better.

Learn more about Visual Recordkeeping

To explore how visual systems change the game across logistics and manufacturing… do not miss our detailed Visual Recordkeeping in Logistics and Manufacturing blog. T his is the one you need to read.

Ready to See what your Supply Chain is missing?

Visual recordkeeping brings clarity across logistics and manufacturing. So, decisions are faster, disputes are fewer and operations stay in control.

See your supply chain as it is. And start operating without blind spots. Contact us today!