Logistics businesses are increasingly using automated number plate recognition systems (ANPR) in their business. And the global ANPR market is expected to grow to $6 billion by 2030 given the number of benefits that you get with the ANPR. Be it improving security or reducing losses, ANPR helps logistics businesses to grow and expand efficiently.

But before implementing the right number plate scanner, it is important to consider some factors.

And that is exactly what we are going to discuss. Well discuss the key factors to consider before choosing the right number plate system for your business.

Considerations When Choosing a Number Plate Scanner

Accuracy and Reliability

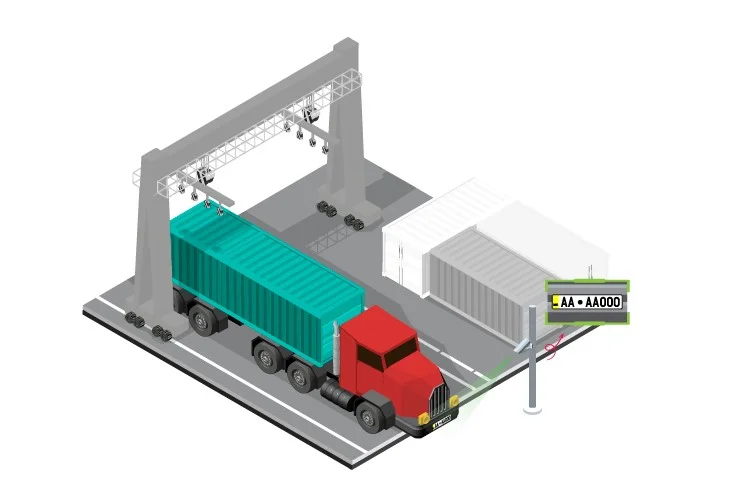

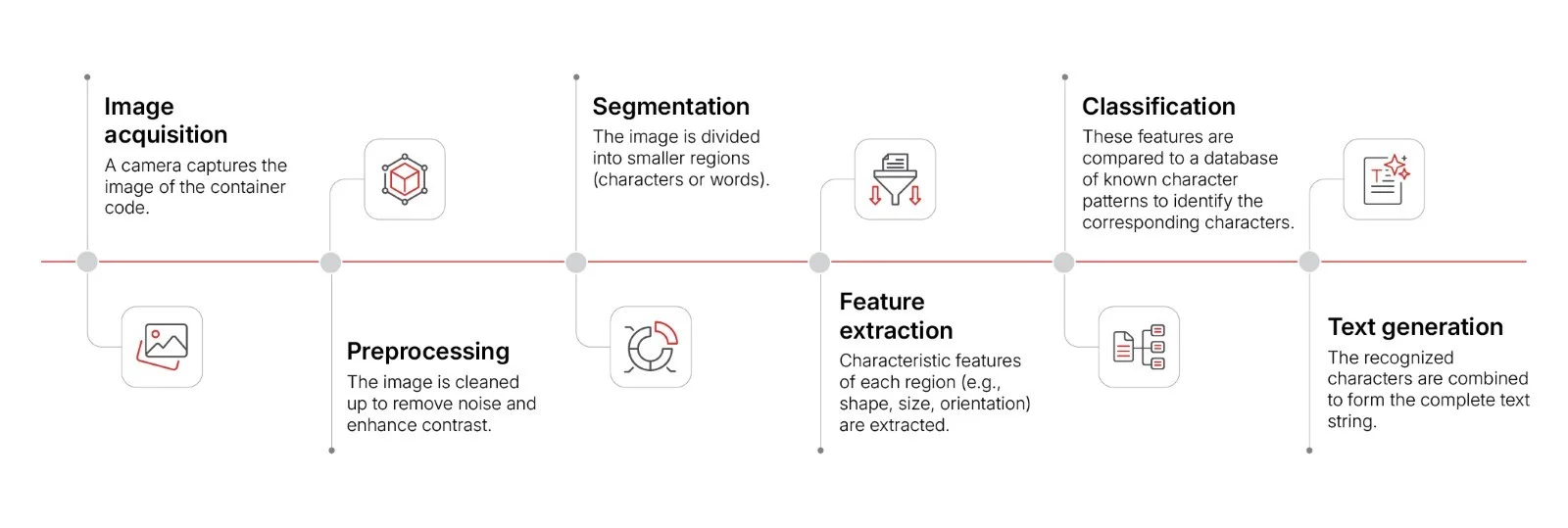

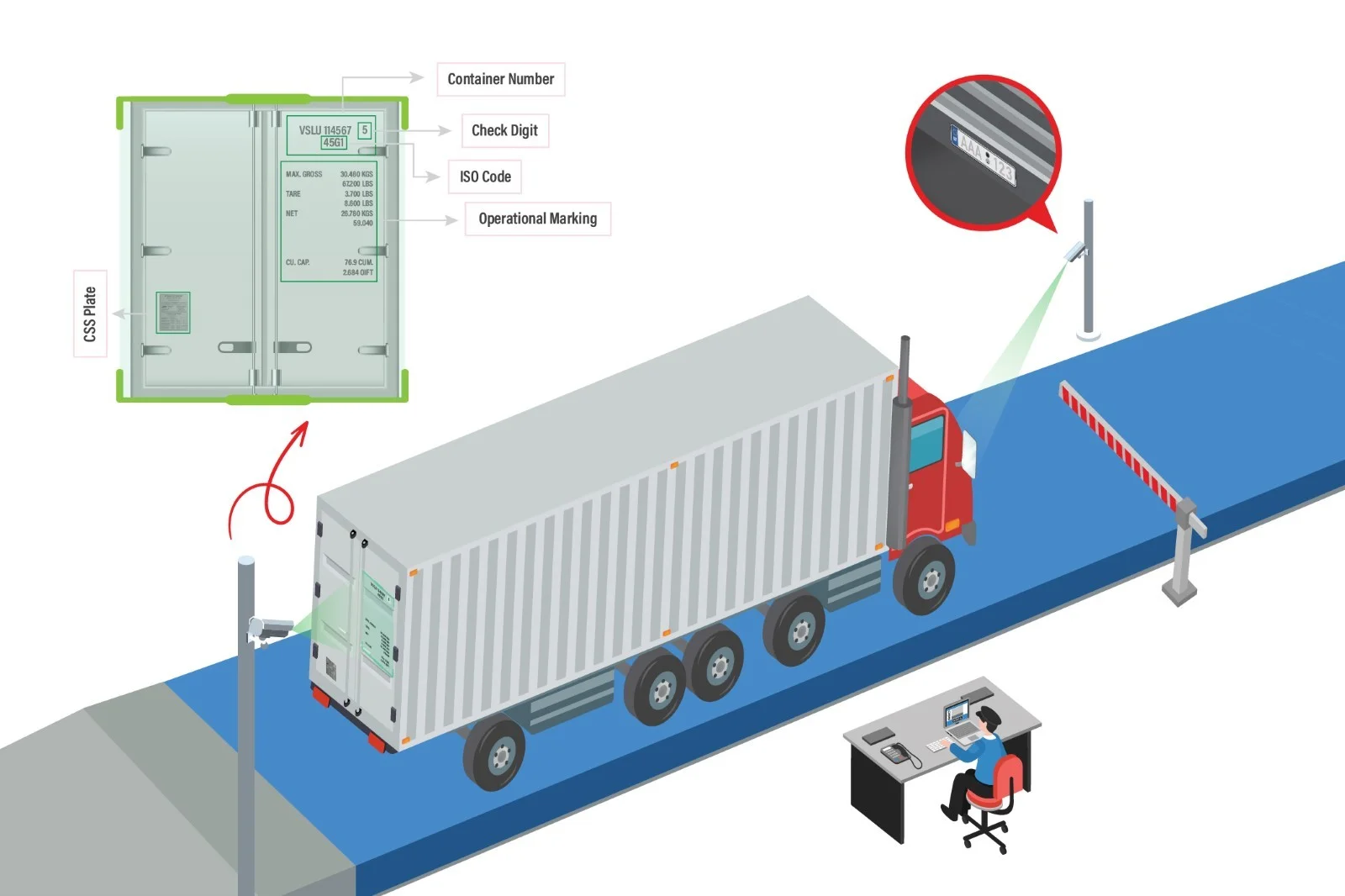

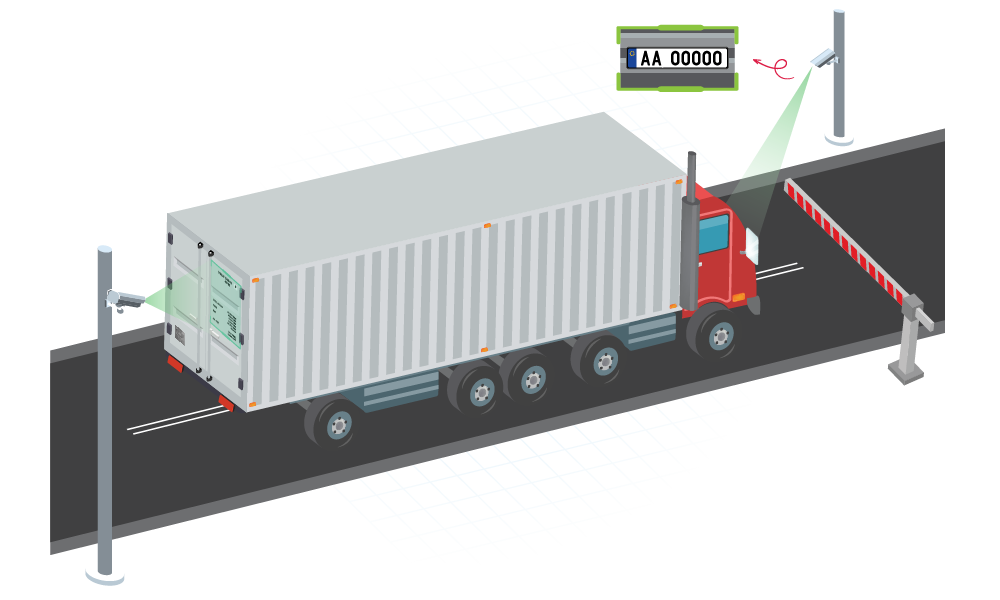

OCR Accuracy: Optical Character Recognition (OCR) technology is the core of every ANPR system. Accurate OCR is important for reading the license plates correctly. So, the OCR technology should be able to do it in different conditions like low light, change in weather conditions and even when the number plates are damaged. Choosing the number plate system with high OCR accuracy helps you avoid errors and maintain smooth operations.

Recognition Speed: Speed is very important in high traffic logistics hubs. So, if your system is able to recognize the number plates faster, the vehicles are processed quickly. It minimizes the delays and helps you manage the large volume of vehicles during peak times.

Error Reduction: False positives and frequent manual checks can be disruptive and time-consuming. A dependable system reduces these errors, ensuring that your operations remain smooth and efficient. With fewer mistakes, your logistics hub can maintain a steady flow of vehicles, improving overall productivity.

Environmental Adaptability

Weather and Lighting Conditions: An effective ANPR system should operate flawlessly regardless of environmental challenges. It should be designed to capture clear images in low light, adjust to glare from headlights, and function reliably in adverse weather conditions like rain or snow. These capabilities are critical for maintaining system accuracy and operational continuity.

Durability and IP Rating: Industrial logistics environment is often harsh and needs to be durable hardware. So, always look for number plate scanners with high IP rating certification. It ensures that your hardware can work under conditions like high dust, moisture, and extreme temperatures. This durability helps your system remain efficient without requiring much maintenance.

Integration with Existing Systems

Warehouse Management and Security Systems: It is a must that your number plate system should integrate with your existing systems. An integrated system can help you automate workflows, such as automatically logging vehicle entries and exits or triggering access gates. It improves efficiency and security.

API and Data Compatibility: Choose a scanning system that is compatible with different software platforms and has robust API support. So you can get real time updates and exchange data smoothly across your systems. It ensures better coordination and visibility for logistics managers.

Scalability and Flexibility

Adaptability to Growing Operations: As your logistics operations expand, so too should your number plate scanning system. A scalable system can accommodate increased vehicle traffic and new locations, helping your technology infrastructure grow with your business needs.

Modular Options: Opting for a modular system provides flexibility to start with a basic setup and add new features or checkpoints as your needs evolve. This approach makes it easier to customize and scale your investment based on operational requirements.

Data Security and Privacy Compliance

Data Encryption: With the sensitive nature of vehicle information, robust data security measures are important. So, encryptions helps you protect the stored data from unauthorized access and potential data breaches.

Compliance with Privacy Regulations: Depending on your location, data privacy laws like GDPR may require you to store and manage license plate data. So, always ensure that your system complies with these regulations to avoid legal complications and hefty fines.

Maintenance and Support

Ongoing Maintenance: Regular software updates and hardware maintenance are important. It minimizes the risk of system downtime and ensures that your ANPR technology remains updated.

Vendor Support and Training: Getting access to reliable vendor support can significantly improve system performance. Additionally, providing training on how to use the system effectively can help you maximize its benefit.

Cost and Return on Investment (ROI)

Initial Investment vs. Operational Savings: The upfront cost of ANPR systems can be high depending on the size of your operations. But they often pay for themselves over time with operational savings. It helps cut the cost of labor, improves efficiency, and delivers better ROI over a course of time.

Total Cost of Ownership: Initial investment is not the only cost involved with ANPR systems. You need software licenses, hardware and future upgrades and it will also add up to your cost. So, a clear understanding of the total cost of ownership will help you make a better decision.

Future-Ready Features

AI and Machine Learning Integration: AI and ML is changing how ANPR is implemented for modern businesses. Be it security, analytics or accuracy, it is helping businesses get better systems. Since they can learn and adapt over time, it really helps modern businesses to keep up with the changing demands.

Cloud and Mobile Compatibility: We are seeing increased use of cloud based and mobile ANPR systems. It helps businesses remotely access and monitor their operations. It offers convenience and is making it more flexible for logistic managers to manage their operations.

Conclusion

It is important to choose a system that meets your current needs. But also consider the flexibility so you can scale and adapt based on future demands.

Need the right ANPR solution for your logistics? Lets connect! Our experts can guide you through system demos and tailor recommendations to optimize your vehicle management and security.