Warehouse Digital Twin

See your warehouse and parking like never before.

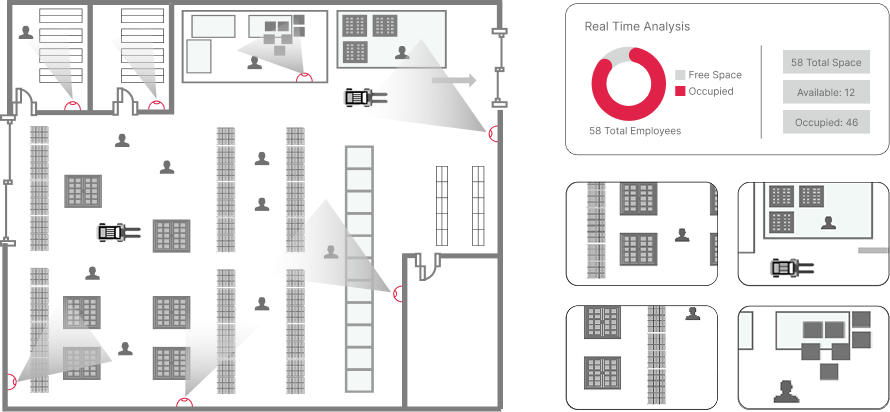

Warehouse Digital Twin is a Smart Warehouse Solutions for Warehouse Monitoring. Plus, analyzes and optimizes occupancy and operations. It creates a virtual replica of your warehouse and parking areas. It is for creating real-time insights into space utilization and performance. It allows for informed decision-making.

Bottlenecks, delays, and reduced efficiency in Warehouse Management are caused due to overcrowded or underutilized warehouse and parking spaces.

Get a live view of space utilization for balancing occupancy and enhancing Warehouse Space Optimization.

Management becomes difficult with limited insights into picker locations, automated vehicle paths, product flow, and parking areas.

You can monitor pickers, vehicles, products, and parking spaces in real time. with a detailed 2D visualization through Warehouse Simulation Software.

Traditional systems cannot anticipate occupancy trends by making proactive decisions difficult.

Our system uses Digital Twin for Supply Chain optimization by forecasting occupancy patterns. So, you can plan and adapt operations effectively.

Static layouts fail to adapt. This increases travel time and reduces efficiency.

Refine your warehouse and parking layout using Warehouse Layout Optimization tools. It is to simplify goods’ flow and minimize travel time.

A virtual replica of the warehouse is beneficial to many stakeholders as it simplifies monitoring and management.

Collect data from CCTVs, sensors, and ERP systems. It is to build the digital twin using Automated Warehouse Management techniques.

Run simulations of workflows and material movement to identify gaps and opportunities for improvement using Smart Warehouse Management.

Integrate the model with live feeds. It is to deliver actionable insights and performance tracking.

Use the insights generated by the system to refine layout, optimize occupancy and scale operations across the warehouse and parking.

Stay updated with the trending and most impactful tech insights. Check out the expert analyses, real-world applications, and forward-thinking ideas that shape the future of AI Computer Vision and innovation.

7:45AM at a busy automotive parts manufacturer. A delivery truck arrived at the dock. Usually, supervisors would take 10 minutes to scan paperwork. They’d also be keying in data. Instead, a camera quietly recorded the container ID, logged upon its arrival. And it tagged the shipment to a specific production line. All without a single […]

CEO & Co-founder

It’s 2:14 PM at a busy CFS gate. A trailer rolls in. The container is old, dusty and sun faded. The number is readable, but only if you look closely. The driver wants to move fast. The queue behind him is growing. The gate operator does what they have always done. Reads the container number. […]

CEO & Co-founder

Modern logistics depend on speed. Accuracy and visibility keep logistics moving. Across container yards and CFS hubs… teams still face blind spots. They rely on manual checks and delayed data. This leads to missed damages and inefficient movement of assets. Logistics teams can see clearly by combining cameras with computer vision. They can understand and […]

CEO & Co-founder