Surface Defect Detection

Detect micro-defects, ensure quality, and reduce wastage with precision AI vision.

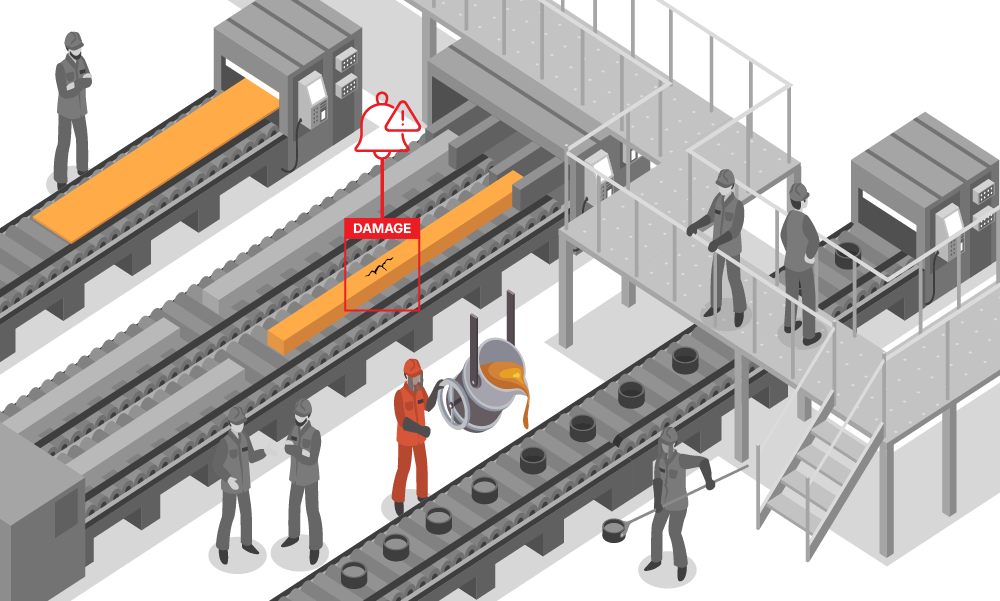

Surface Defect Detection powered by AI computer vision transforms quality control in the steel industry. It automatically scans hot and cold rolled surfaces to identify cracks, scale, pinholes, laminations, dents, or scratches in real time, well before they move further in the process.

Surface flaws like pinholes, cracks, or inclusions often go unnoticed during visual inspections, leading to high rejection rates later.

Human-led surface checks are inconsistent, prone to fatigue, and may vary across shifts or lighting conditions.

Defects are often caught too late, after finishing or packaging, wasting time, effort, and material.

Manual checks or re-inspections cause bottlenecks, slowing down continuous steel production.

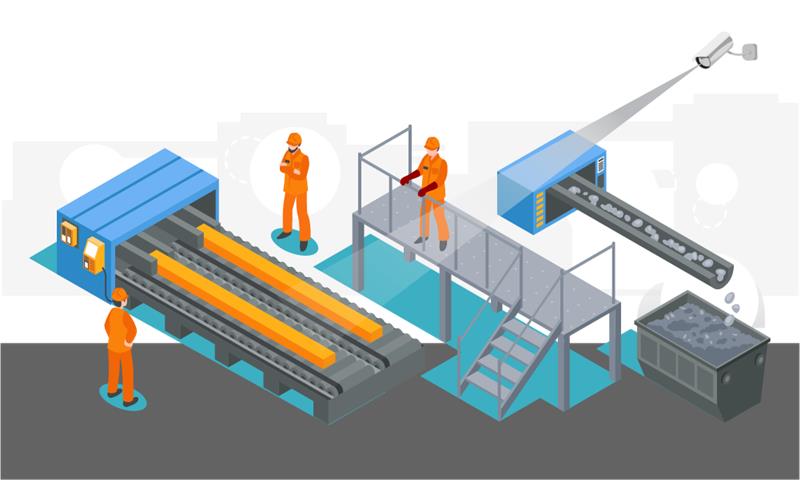

Captures ultra-clear visuals of steel surfaces to detect even the smallest of irregularities in real time.

Deep learning models trained to identify, categorize, and prioritize various surface defects instantly.

Operators receive instant notifications with defect type, location, and severity, enabling fast action.

Easily deployable on existing production lines without disrupting the process or requiring infrastructure overhaul.

Before cameras are placed, our team works closely with your QA and production heads to identify key defect-prone zones in your process, from roughing to finishing stages.

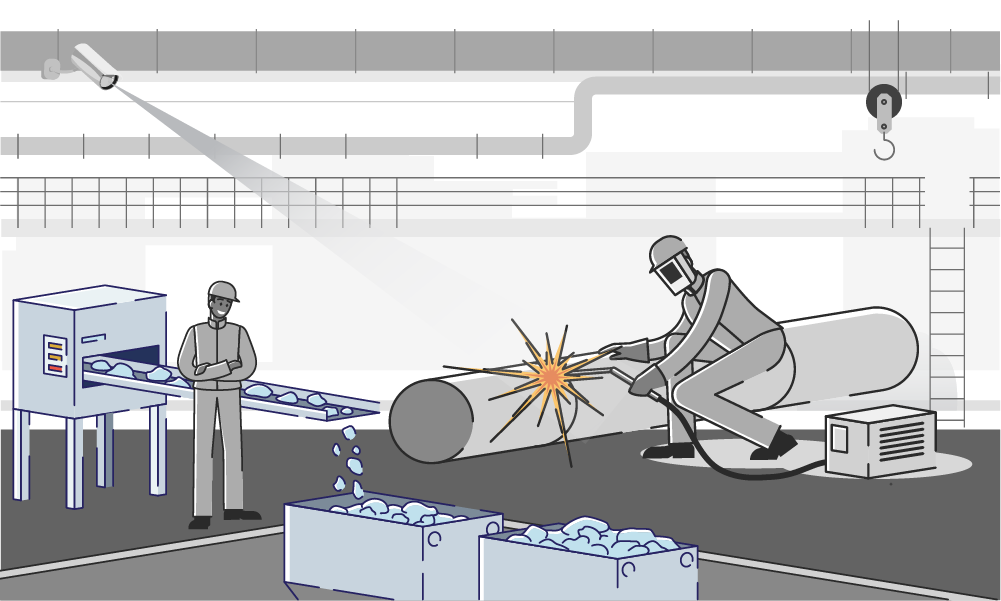

Unlike container OCR or standard object detection, steel surfaces require adaptive camera calibration to handle hot metal glare, scale, and high-speed movement. We tune exposure, frame rate, and sensor placement accordingly.

Using your past defect data (images, logs), we build a steel-grade-specific model that understands localized terminology and defect variations, whether its centerline cracks or transverse marks.

The model is installed alongside your HMI or MES systems. We enable shift-level visibility, automatic tagging for rework, and live dashboards. Testing is done under real heat-load, ambient light, and line-speed conditions.

Stay updated with the trending and most impactful tech insights. Check out the expert analyses, real-world applications, and forward-thinking ideas that shape the future of AI Computer Vision and innovation.

7:45AM at a busy automotive parts manufacturer. A delivery truck arrived at the dock. Usually, supervisors would take 10 minutes to scan paperwork. They’d also be keying in data. Instead, a camera quietly recorded the container ID, logged upon its arrival. And it tagged the shipment to a specific production line. All without a single […]

CEO & Co-founder

It’s 2:14 PM at a busy CFS gate. A trailer rolls in. The container is old, dusty and sun faded. The number is readable, but only if you look closely. The driver wants to move fast. The queue behind him is growing. The gate operator does what they have always done. Reads the container number. […]

CEO & Co-founder

Modern logistics depend on speed. Accuracy and visibility keep logistics moving. Across container yards and CFS hubs… teams still face blind spots. They rely on manual checks and delayed data. This leads to missed damages and inefficient movement of assets. Logistics teams can see clearly by combining cameras with computer vision. They can understand and […]

CEO & Co-founder