Safety Monitoring

Enhance worker safety in the industrial environment with AI.

Large vehicles, heavy equipment and hazardous environment make industrial facilities and sites a risky place to work if the workers are negligent. Yet, given the nature of these workplaces, its not possible to ensure safety for all just by human supervision. But with AI computer vision, the scenario changes with 24×7 monitoring and instant safety alerts.

It is not possible to detect every safety violation by every worker by simply relying on manual monitoring.

Computer vision tracks safety gear usage like PPE and adherence to other protocols, alerting in real time.

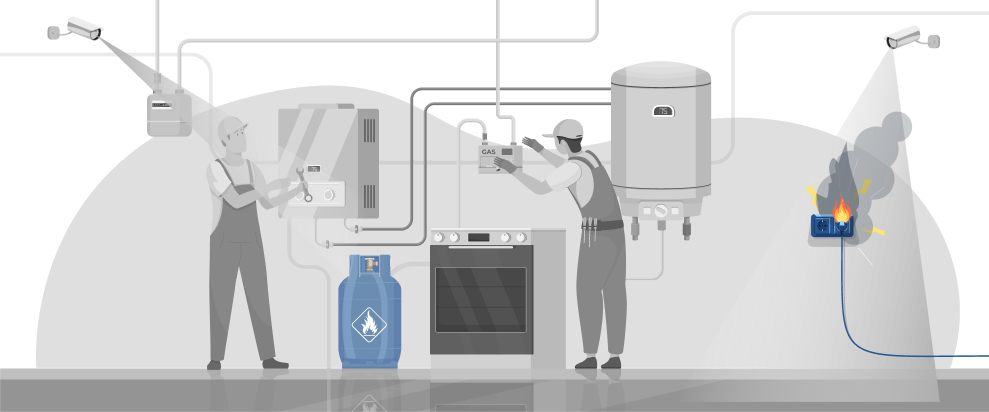

Unauthorized personnel or vehicles entering high-risk zones can cause accidents and safety risks.

AI processes real-time surveillance identifies unauthorized movements and triggers instant alerts.

Unable to detect an accident in timely manner leads to further escalation and increased risk.

AI can rapidly identify incidents and send alerts to safety teams, enabling swift mitigation activity.

Manual safety logs lack real-time accuracy and insights which can help improve the processes and operations.

Automatically generated real-time safety reports can help strengthen risk management activities and process improvements.

Safety monitoring is critical for every industry, but industries with high safety risks benefit more from it. It helps them enhance the safety of workers and daily operations.

We analyze the existing setup to ensure safety protocols and integrate AI-powered monitoring solutions.

The system learns risk patterns, unsafe activities and behavior, compliance checks, etc.

AI system monitors the environment to detect violations and prevent accidents by sending real-time alerts.

AI generated insights help in enhancing safety adherence and regulatory compliance, and plan future course of actions.

Stay updated with the trending and most impactful tech insights. Check out the expert analyses, real-world applications, and forward-thinking ideas that shape the future of AI Computer Vision and innovation.

7:45AM at a busy automotive parts manufacturer. A delivery truck arrived at the dock. Usually, supervisors would take 10 minutes to scan paperwork. They’d also be keying in data. Instead, a camera quietly recorded the container ID, logged upon its arrival. And it tagged the shipment to a specific production line. All without a single […]

CEO & Co-founder

It’s 2:14 PM at a busy CFS gate. A trailer rolls in. The container is old, dusty and sun faded. The number is readable, but only if you look closely. The driver wants to move fast. The queue behind him is growing. The gate operator does what they have always done. Reads the container number. […]

CEO & Co-founder

Modern logistics depend on speed. Accuracy and visibility keep logistics moving. Across container yards and CFS hubs… teams still face blind spots. They rely on manual checks and delayed data. This leads to missed damages and inefficient movement of assets. Logistics teams can see clearly by combining cameras with computer vision. They can understand and […]

CEO & Co-founder