Resist Coating Uniformity & Defect Monitoring

Perfect the Coat. Eliminate Contamination. Ensure Photolithography Precision.

Photoresist coating is the first critical step in wafer patterning, any variation in film thickness, streaks, or contamination can cause pattern distortion or complete lithography failure. Yet, traditional inline checks or manual inspections often miss these subtle but fatal errors.

AI-powered Resist Coating Uniformity & Defect Monitoring uses computer vision to continuously inspect resist film application in real-time. It tracks film consistency, detects defects like bubbles, streaks, and particles, and identifies non-uniform thickness across the wafer, before the wafer reaches the exposure tool.

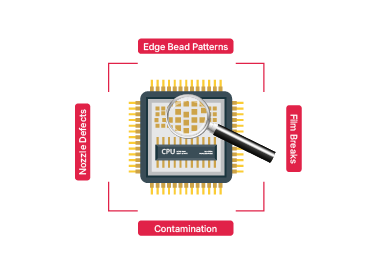

Variations across wafer radius or from batch-to-batch can result in uneven exposure or resist development.

Bubbles, streaks, or particles are difficult to catch without consistent high-resolution inspection.

Poor edge bead removal (EBR) or aging resist causes contamination at the wafer edge, reducing usable area.

Defects are often discovered only after exposure or development, too late for correction.

High-speed cameras scan coated wafers for surface anomalies and coating consistency before exposure.

Visual data is processed to detect microns of variation across wafer zones and flag abnormal patterns.

Identifies EBR failures, air bubble entrapments, and inconsistent spin profiles that can compromise quality.

Automatically stops defective wafers from progressing and recommends rework, saving exposure tool cycles.

We begin by identifying the optimal inspection point, typically between the spin coater and EBR or before bake, to ensure full visual access before exposure.

Camera and lighting systems are tuned to work across multiple resist chemistries and coating speeds, with configurable profiles for each product line.

Our models are trained using historical coated wafer data, including edge bead patterns, film breaks, nozzle defects, and particulate contamination.

The inspection system sends “pass,” “hold,” or “re-coat” commands directly to your MES system, while simultaneously logging heatmaps and coating stats per wafer ID for traceability.

Stay updated with the trending and most impactful tech insights. Check out the expert analyses, real-world applications, and forward-thinking ideas that shape the future of AI Computer Vision and innovation.

7:45AM at a busy automotive parts manufacturer. A delivery truck arrived at the dock. Usually, supervisors would take 10 minutes to scan paperwork. They’d also be keying in data. Instead, a camera quietly recorded the container ID, logged upon its arrival. And it tagged the shipment to a specific production line. All without a single […]

CEO & Co-founder

It’s 2:14 PM at a busy CFS gate. A trailer rolls in. The container is old, dusty and sun faded. The number is readable, but only if you look closely. The driver wants to move fast. The queue behind him is growing. The gate operator does what they have always done. Reads the container number. […]

CEO & Co-founder

Modern logistics depend on speed. Accuracy and visibility keep logistics moving. Across container yards and CFS hubs… teams still face blind spots. They rely on manual checks and delayed data. This leads to missed damages and inefficient movement of assets. Logistics teams can see clearly by combining cameras with computer vision. They can understand and […]

CEO & Co-founder