Relief Effort Coordination

Effective disaster response with the efficiency of AI.

Our relief effort coordination solution uses AI and computer vision to analyze disaster-affected areas. It helps in assessing damage levels and optimizing resource allocation. It’s a great aid for emergency responders and helps organizations streamline operations and maximize impact

Human-led manual assessment of disaster zones slows down aid distribution.

Our solution rapidly evaluates affected areas and prioritizes resource deployment based on real-time needs.

Lack of proper coordination and insights often lead to resource wastage or shortages.

AI analyzes supply chains and suggests efficient routes for aid distribution where needed, on time.

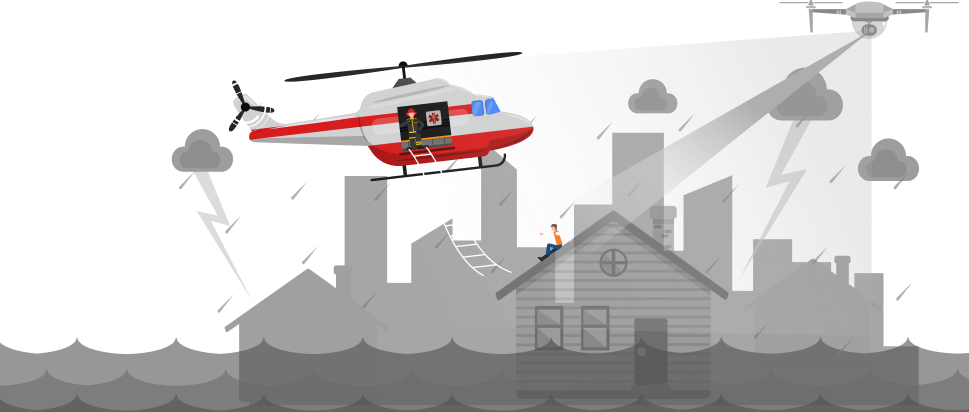

Its difficult to find stranded individuals in large disaster zones with any real-time knowledge.

Improve rescue operations as our system uses drone and satellite imagery to identify and locate survivors.

Communication becomes difficult in disaster struck areas due to damaged infrastructure.

Guidance by AI can help set up other communication networks and optimize response efforts.

This solution is crucial for organizations and agencies who are involved in disaster management.

Using drones, satellite imagery and on-ground reports, real-time data is gathered.

Affected area is analyzed and the severity of destruction is determined through it.

Delivery routes are prioritized with the help of AI and resources are distributed effectively.

Live tracking is enabled for relief efforts with real-time data and insights, helping in streamlining operations.

Stay updated with the trending and most impactful tech insights. Check out the expert analyses, real-world applications, and forward-thinking ideas that shape the future of AI Computer Vision and innovation.

7:45AM at a busy automotive parts manufacturer. A delivery truck arrived at the dock. Usually, supervisors would take 10 minutes to scan paperwork. They’d also be keying in data. Instead, a camera quietly recorded the container ID, logged upon its arrival. And it tagged the shipment to a specific production line. All without a single […]

CEO & Co-founder

It’s 2:14 PM at a busy CFS gate. A trailer rolls in. The container is old, dusty and sun faded. The number is readable, but only if you look closely. The driver wants to move fast. The queue behind him is growing. The gate operator does what they have always done. Reads the container number. […]

CEO & Co-founder

Modern logistics depend on speed. Accuracy and visibility keep logistics moving. Across container yards and CFS hubs… teams still face blind spots. They rely on manual checks and delayed data. This leads to missed damages and inefficient movement of assets. Logistics teams can see clearly by combining cameras with computer vision. They can understand and […]

CEO & Co-founder