Real-time Inventory Tracking

Simplified inventory management with real-time visibility.

Incorrect or outdated inventory data can cost both money and efficiency. We use AI computer vision inventory management to optimize operations. It is done through Automated Inventory Management. This ensures real-time stock tracking by reducing waste. It provides full transparency across the supply chain.

Traditional methods lack responsiveness. Our Inventory Visibility Solutions provide live updates. It improves inventory accuracy and decision-making.

Traditional methods lack responsiveness. Our Inventory Visibility Solutions provide live updates. It improves inventory accuracy and decision-making.

Manual methods often result in errors like overstocking or understocking. Our Warehouse inventory tracking eliminates these issues through automation.

Real-time tracking by AI ensures inventory accuracy. It even improves efficiency at every level.

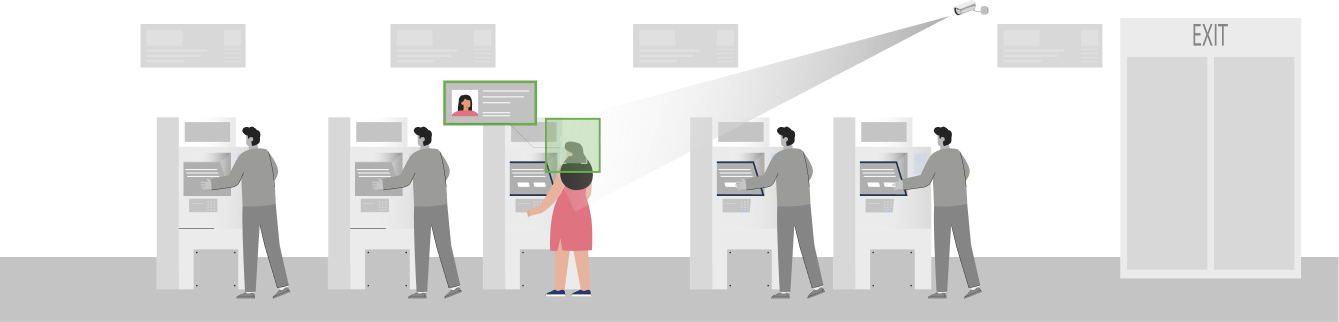

Limited data flow slows operations. We ensure continuous visibility into stock movement with CCTV Monitoring Systems.

Gain smart warehouse management capabilities with end-to-end inventory status tracking across all touchpoints.

Inefficiencies in traditional methods inflate operational expenses.

You maintain the right stock levels, reduce waste, and avoid missed sales by using AI for inventory management.

Real-time inventory tracking is used by a variety of stakeholders as it boosts operational efficiency and inventory level accuracy.

CCTVs and IoT sensors are deployed to monitor inventory status in real time.

Inventory data is captured continuously and processed for insights and alerts.

AI models are trained to recognize items, optimize storage, and predict demand.

Our solution integrates seamlessly with your ERP/WMS for full automation.

Stay updated with the trending and most impactful tech insights. Check out the expert analyses, real-world applications, and forward-thinking ideas that shape the future of AI Computer Vision and innovation.

7:45AM at a busy automotive parts manufacturer. A delivery truck arrived at the dock. Usually, supervisors would take 10 minutes to scan paperwork. They’d also be keying in data. Instead, a camera quietly recorded the container ID, logged upon its arrival. And it tagged the shipment to a specific production line. All without a single […]

CEO & Co-founder

It’s 2:14 PM at a busy CFS gate. A trailer rolls in. The container is old, dusty and sun faded. The number is readable, but only if you look closely. The driver wants to move fast. The queue behind him is growing. The gate operator does what they have always done. Reads the container number. […]

CEO & Co-founder

Modern logistics depend on speed. Accuracy and visibility keep logistics moving. Across container yards and CFS hubs… teams still face blind spots. They rely on manual checks and delayed data. This leads to missed damages and inefficient movement of assets. Logistics teams can see clearly by combining cameras with computer vision. They can understand and […]

CEO & Co-founder