Quality Control

Achieve superior product quality with intelligent defect detection.

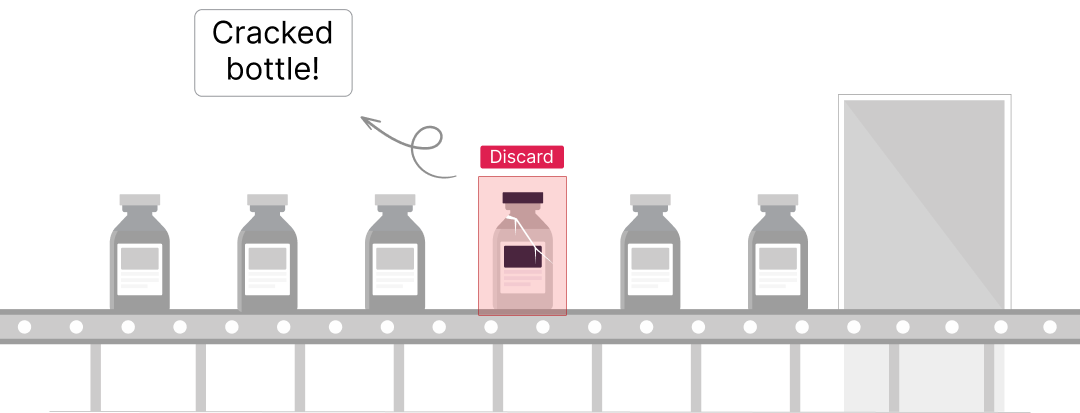

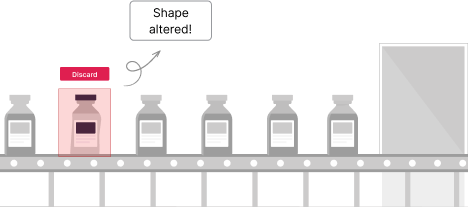

AI computer vision detects defects in the production that human inspection might miss. Computer vision for quality control helps automate quality checks to help manufacturers get better quality output. Plus, consistency in product standards and reduction in product waste.

Manual inspections are prone to human errors. It is due to a number of reasons like fatigue.

AI systems scan products with high accuracy. It identifies even the smallest defects in real time. It ensures manufacturing quality assurance.

Traditional quality control processes slow down production lines and increase operational costs. This is where automated quality inspection offers a faster and more reliable alternative.

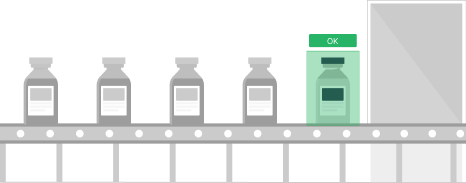

AI enables instant quality checks, without any interruptions. This ensures seamless production and supports quality control automation.

Detecting defects too late in the process? This leads to material wastage and increased costs. Implementing automated defect detection helps address this problem.

Our AI system identifies flaws at the earliest stage in real time. This reduces rework and waste. This is a key part of an automated quality control inspection process.

There is variation in inspection which leads to quality deviation with different product inspectors. A smart inspection system provides consistency and reduces variation.

AI ensures uniform quality checks across all production batches by maintaining quality standards. It is done with the help of computer vision for quality control.

Ensuring the products meet the set quality standards. This is an absolute must for all manufacturers. Thus, the use case is beneficial to many stakeholders.

We evaluate your existing camera infrastructure to integrate the solution seamlessly.

Capture high-resolution images of the product and from production lines to train the AI model.

We integrate AI inspections into existing manufacturing workflows. It is for continuous inspection using automated quality control integration techniques.

Real-time insights and detailed reports are generated for continuous improvement in quality control.

Stay updated with the trending and most impactful tech insights. Check out the expert analyses, real-world applications, and forward-thinking ideas that shape the future of AI Computer Vision and innovation.

7:45AM at a busy automotive parts manufacturer. A delivery truck arrived at the dock. Usually, supervisors would take 10 minutes to scan paperwork. They’d also be keying in data. Instead, a camera quietly recorded the container ID, logged upon its arrival. And it tagged the shipment to a specific production line. All without a single […]

CEO & Co-founder

It’s 2:14 PM at a busy CFS gate. A trailer rolls in. The container is old, dusty and sun faded. The number is readable, but only if you look closely. The driver wants to move fast. The queue behind him is growing. The gate operator does what they have always done. Reads the container number. […]

CEO & Co-founder

Modern logistics depend on speed. Accuracy and visibility keep logistics moving. Across container yards and CFS hubs… teams still face blind spots. They rely on manual checks and delayed data. This leads to missed damages and inefficient movement of assets. Logistics teams can see clearly by combining cameras with computer vision. They can understand and […]

CEO & Co-founder