Production Line Health Monitoring

Predict faults. Prevent downtime. Maintain flow across every stage of steel production.

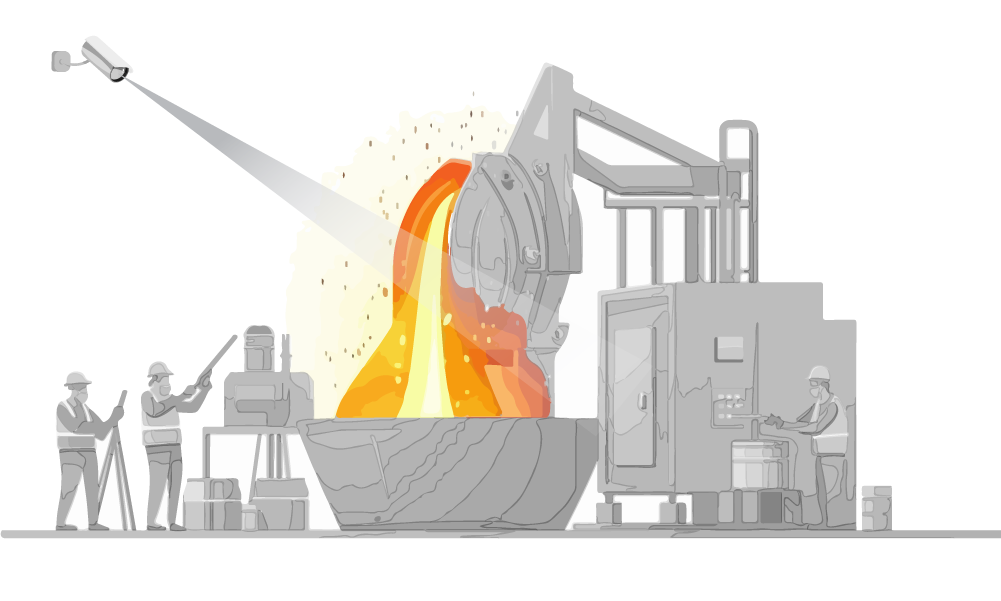

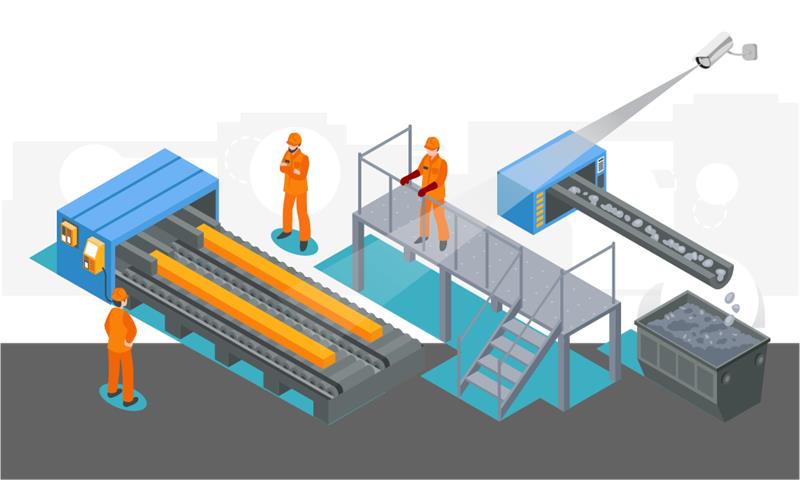

Steel plants run on tight schedules and continuous operations. Unexpected machine halts, roller jams, or misaligned components can halt the entire line, causing delays, losses, and unsafe conditions. Production Line Health Monitoring uses computer vision to track the physical and functional condition of moving components in real time, rollers, conveyors, cooling beds, tension arms, and more.

A single fault in conveyors or rollers can halt the entire line, causing cascading delays.

Most steel lines depend on fixed maintenance schedules, missing early signs of wear or damage.

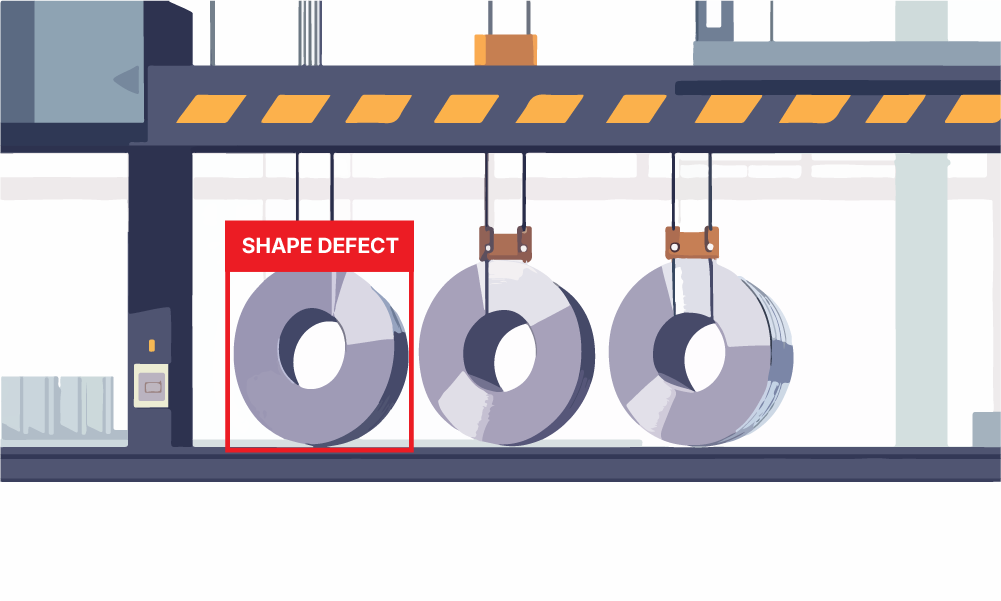

Without continuous vision, misalignments or heat-induced warping often go unnoticed.

Operators typically detect issues only after they affect the finished product or cause stoppages.

AI models detect wear on rollers, chains, and belts based on visua degradation.

Detects off-center movement, skewed alignment, or unusual material buildup.

Integrates thermal vision to track heat-induced component distortion.

Live condition monitoring with auto-alerts and maintenance request initiation.

We begin by auditing your rolling and conveyor lines, identifying high-friction, high-failure, or heat-sensitive sections.

Cameras are paired with thermal and vibration sensors at key points, like tension zones, curved conveyors, and cooling beds, for a complete mechanical picture.

Our models are trained on live data from your plant to distinguish between normal operational variations and early-stage degradation, belt slack, or roller wobble.

When anomalies are detected, the system auto-generates fault logs and routes them to maintenance teams. This allows for scheduled interventions without shutting down entire sections.

Stay updated with the trending and most impactful tech insights. Check out the expert analyses, real-world applications, and forward-thinking ideas that shape the future of AI Computer Vision and innovation.

7:45AM at a busy automotive parts manufacturer. A delivery truck arrived at the dock. Usually, supervisors would take 10 minutes to scan paperwork. They’d also be keying in data. Instead, a camera quietly recorded the container ID, logged upon its arrival. And it tagged the shipment to a specific production line. All without a single […]

CEO & Co-founder

It’s 2:14 PM at a busy CFS gate. A trailer rolls in. The container is old, dusty and sun faded. The number is readable, but only if you look closely. The driver wants to move fast. The queue behind him is growing. The gate operator does what they have always done. Reads the container number. […]

CEO & Co-founder

Modern logistics depend on speed. Accuracy and visibility keep logistics moving. Across container yards and CFS hubs… teams still face blind spots. They rely on manual checks and delayed data. This leads to missed damages and inefficient movement of assets. Logistics teams can see clearly by combining cameras with computer vision. They can understand and […]

CEO & Co-founder