Plasma Etching Endpoint Detection

Stop at the Right Moment. Control Every Nanometer.

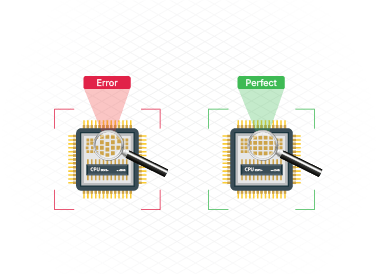

In plasma etching, precision is everything. Etching for too long or stopping too early can compromise critical dimensions, reduce layer selectivity, and ruin yield. Traditional endpoint detection methods, like time-based controls or optical emission spectroscopy (OES), are often reactive, not predictive. AI-powered Plasma Etching Endpoint Detection leverages real-time camera feeds to visually monitor plasma characteristics. By analyzing glow patterns, intensity shifts, and arc behavior using machine learning, it predicts when to stop the etch, improving accuracy and protecting underlying layers.

Static timers don’t account for batch variation, chamber condition, or etch rate drift.

Emission-based or pressure-based systems often detect endpoint after it’s already passed.

Subtle anomalies in plasma arcs or intensity gradients can signal defects, if you can see them.

Operators lack real-time visual understanding of chamber dynamics during critical steps.

Tracks changes in plasma color, intensity, and pattern using high-contrast vision feeds.

Learns typical endpoint behavior across recipes and alerts for deviation or completion.

Adapts to different gases, pressures, and materials (e.g., Si, GaN, III-V) with retrainable models.

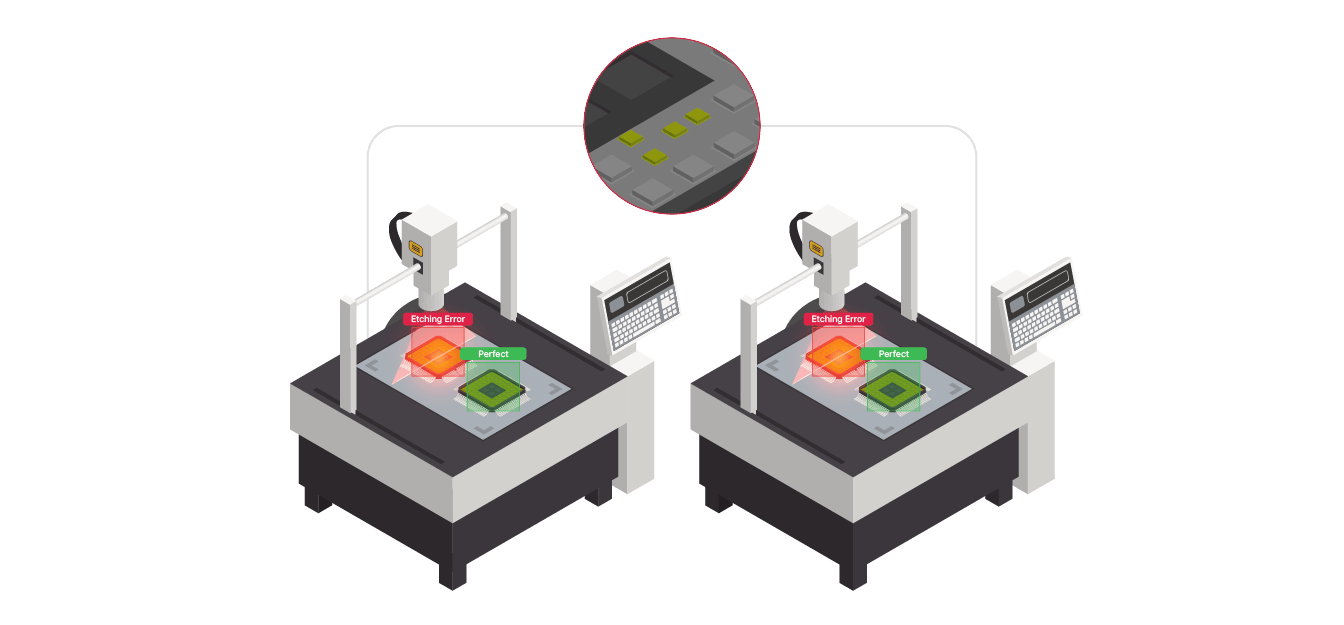

Triggers system alerts and interacts with tool PLC to suggest or automate etch stop action.

We collaborate with your tool vendor or internal automation team to identify optimal camera mount points within or outside the plasma chamber viewport, ensuring thermal safety and visibility.

Each etch recipe is captured and analyzed to build a baseline library of endpoint glow patterns, pressure shifts, and color transitions under different gases and process parameters.

The model is trained on known endpoint glow profiles across Si, SiN, SiO₂, and other layers, helping detect subtle shifts that indicate true endpoint vs. noise.

Once the AI model predicts an endpoint, it sends real-time flags to the tool controller, triggering a suggestive or automatic stop action. All endpoint data is logged for traceability and process audits.

Stay updated with the trending and most impactful tech insights. Check out the expert analyses, real-world applications, and forward-thinking ideas that shape the future of AI Computer Vision and innovation.

7:45AM at a busy automotive parts manufacturer. A delivery truck arrived at the dock. Usually, supervisors would take 10 minutes to scan paperwork. They’d also be keying in data. Instead, a camera quietly recorded the container ID, logged upon its arrival. And it tagged the shipment to a specific production line. All without a single […]

CEO & Co-founder

It’s 2:14 PM at a busy CFS gate. A trailer rolls in. The container is old, dusty and sun faded. The number is readable, but only if you look closely. The driver wants to move fast. The queue behind him is growing. The gate operator does what they have always done. Reads the container number. […]

CEO & Co-founder

Modern logistics depend on speed. Accuracy and visibility keep logistics moving. Across container yards and CFS hubs… teams still face blind spots. They rely on manual checks and delayed data. This leads to missed damages and inefficient movement of assets. Logistics teams can see clearly by combining cameras with computer vision. They can understand and […]

CEO & Co-founder