PHOTOMASK DEFECT INSPECTION

Catch Sub-Micron Errors. Preserve Pattern Integrity. Enhance Yield at the First Step.

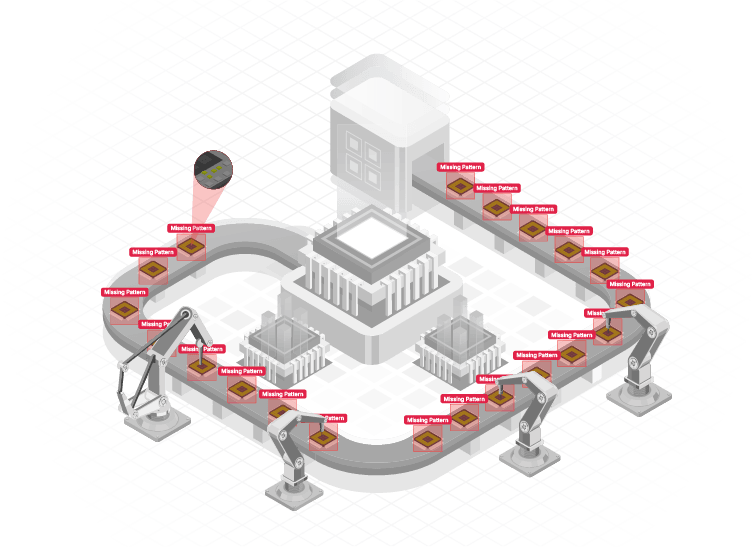

Photomasks are the blueprint of semiconductor manufacturing, and even the tiniest imperfection can lead to costly wafer defects across thousands of chips. Traditional manual and rule-based inspections are no longer viable for today’s advanced nodes. AI-powered Photomask Defect Inspection leverages ultra-high-resolution imaging combined with deep learning to detect sub-micron flaws like missing patterns, particles, scratches, or deformation, before they are replicated during lithography.

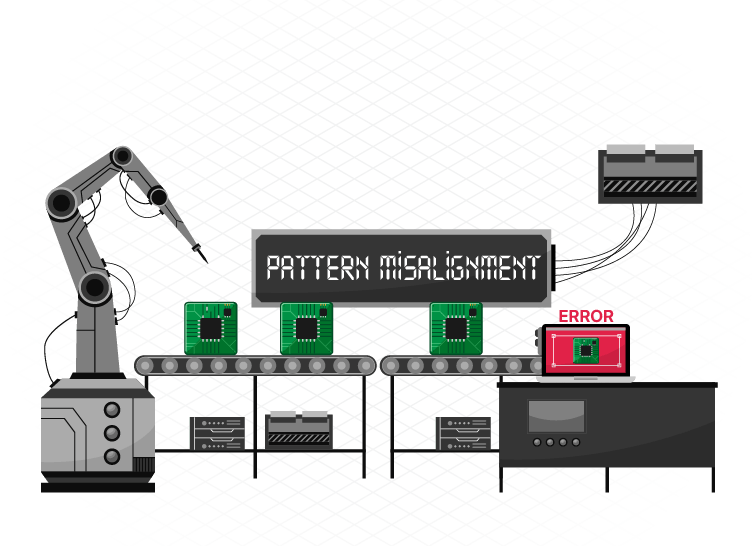

Human inspection or traditional rule-based systems struggle to catch nano-scale particles or structural flaws on masks.

High rejection rate of usable masks due to overly sensitive or static threshold systems.

Even when defects are detected, they are often not correctly categorized, slowing down root cause analysis.

Long inspection cycles and repeated mask validations delay exposure steps and increase cycle times.

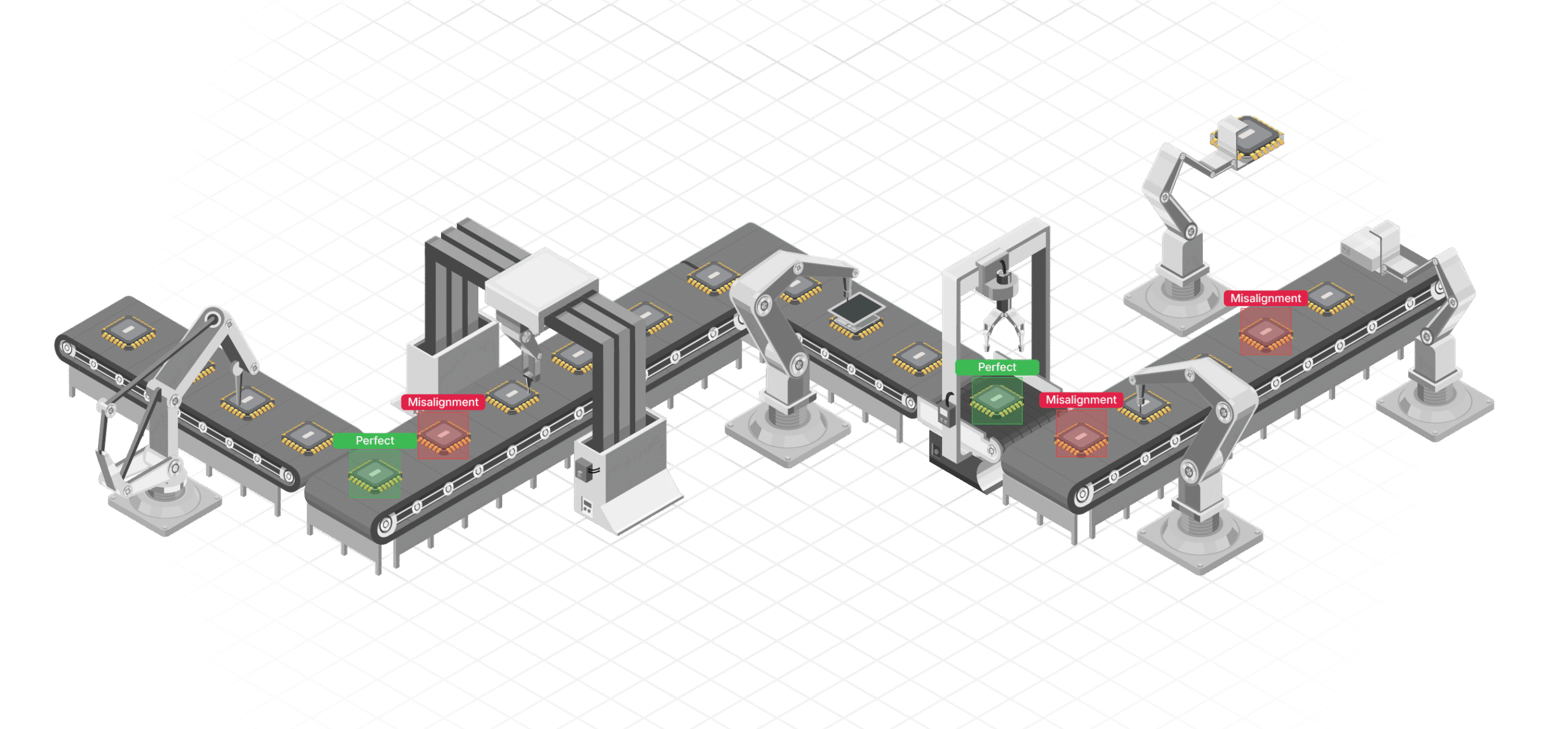

AI models trained on vast defect datasets to detect and differentiate critical vs. non-critical anomalies.

Micron and sub-micron precision imaging using specialized optics to catch the smallest pattern inconsistencies.

Classifies defect types (particles, scratches, edge defects, missing lines) and ranks them by severity and location.

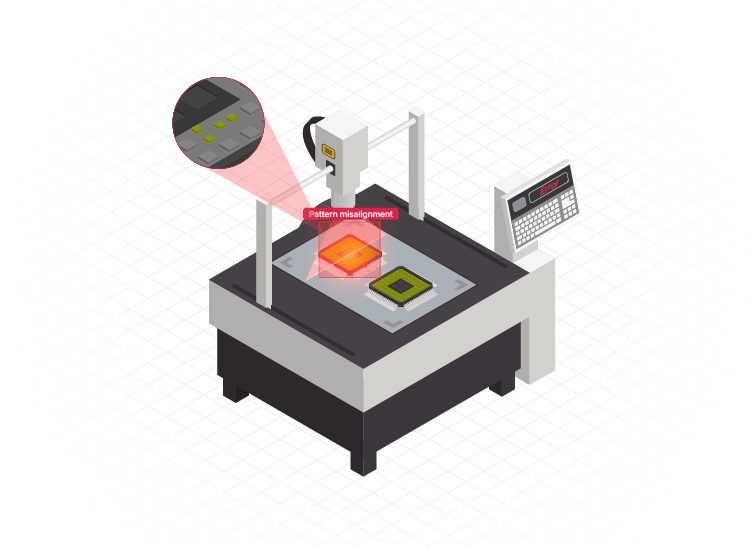

Compares actual mask pattern with design files (GDSII) for pixel-level mismatch detection.

The system begins by ingesting GDSII design files of the intended mask layout. These files are used to create pixel-level reference patterns for comparison.

Specialized imaging systems are calibrated to achieve ultra-high resolution (sub-100nm) and correct for lens distortion, lighting uniformity, and reflectivity of mask surfaces.

Historical mask defect data, including particle types, line breaks, and haze, is used to train a defect classification model that distinguishes real issues from noise or permissible variations.

Captured images are analyzed frame-by-frame using AI models, and inspection results are displayed on an intuitive dashboard. Critical defects are flagged for review, while acceptable ones are auto-classified, reducing manual load.

Stay updated with the trending and most impactful tech insights. Check out the expert analyses, real-world applications, and forward-thinking ideas that shape the future of AI Computer Vision and innovation.

7:45AM at a busy automotive parts manufacturer. A delivery truck arrived at the dock. Usually, supervisors would take 10 minutes to scan paperwork. They’d also be keying in data. Instead, a camera quietly recorded the container ID, logged upon its arrival. And it tagged the shipment to a specific production line. All without a single […]

CEO & Co-founder

It’s 2:14 PM at a busy CFS gate. A trailer rolls in. The container is old, dusty and sun faded. The number is readable, but only if you look closely. The driver wants to move fast. The queue behind him is growing. The gate operator does what they have always done. Reads the container number. […]

CEO & Co-founder

Modern logistics depend on speed. Accuracy and visibility keep logistics moving. Across container yards and CFS hubs… teams still face blind spots. They rely on manual checks and delayed data. This leads to missed damages and inefficient movement of assets. Logistics teams can see clearly by combining cameras with computer vision. They can understand and […]

CEO & Co-founder