Package-On-Package (PoP) Assembly Validation

Verify Every Layer. Validate Every Connection. Stack with Confidence.

Package-on-Package (PoP) is central to high-density mobile and consumer electronics, allowing multiple dies to be vertically integrated. But even the slightest vertical misalignment, offset solder balls, or warpage can lead to latent electrical failures that are hard to catch during final testing.

AI-powered PoP Assembly Validation uses advanced computer vision systems to inspect stacked die alignment, verify solder ball contact, and confirm Z-axis symmetry before the final reflow step. These inspections ensure mechanical integrity, electrical continuity, and proper height uniformity across units.

Even a slight X-Y or rotational offset between the top and bottom packages can compromise interconnects.

Incomplete, tilted, or shifted ball contacts often go undetected until after reflow or in final test.

Mechanical stress during stacking can deform the top die, leading to contact failure or packaging instability.

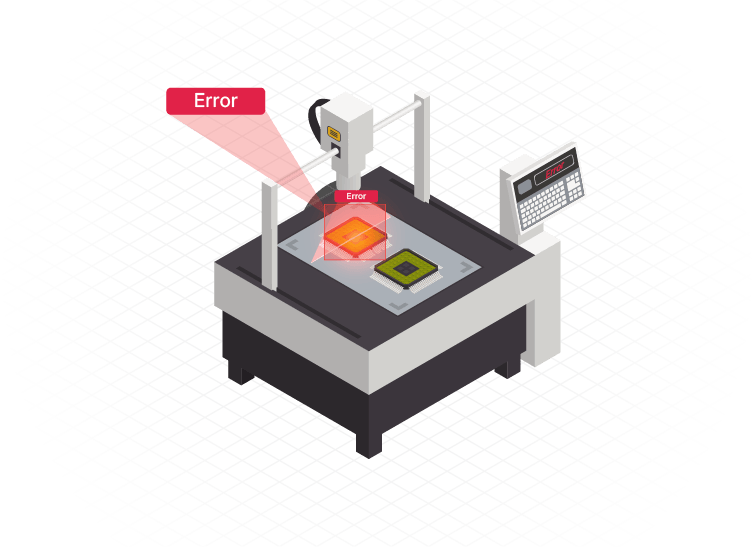

Manual or 2D inspection can’t detect vertical skew or stack height irregularities, which are critical in PoP.

Captures vertical alignment, height, and planarity using stereo or laser triangulation imaging.

AI verifies the concentricity and location of each solder ball against landing pads across layers.

Detects bowing, tilt, or sagging in the top die pre-reflow, reducing latent defect risks.

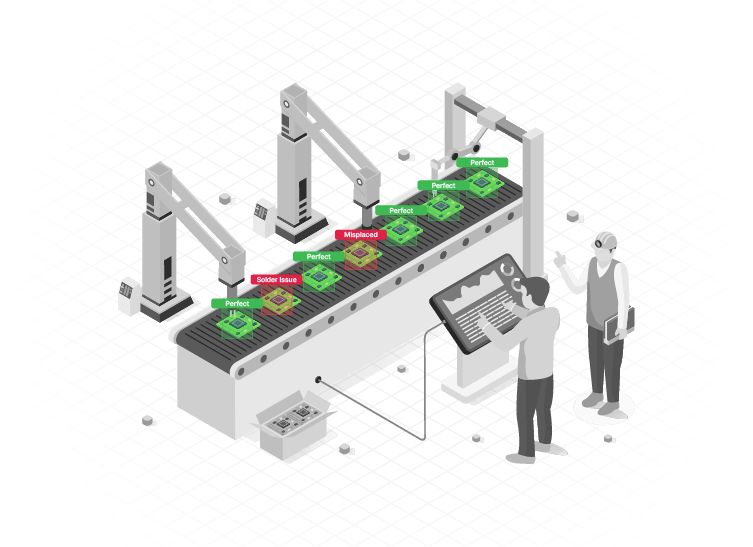

Assigns assembly units into pass/fail/rework bins based on deviation from set tolerances.

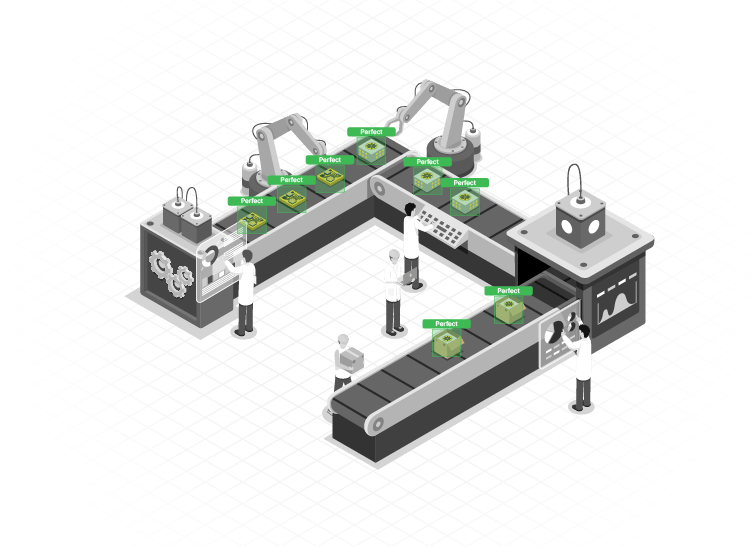

We begin by identifying the optimal point for PoP validation, usually after top package placement but before reflow. Fixture mapping includes robotic arm paths and hold time.

Combining top-down visual inspection with structured light or laser triangulation systems, we capture full X-Y-Z data of the stacked unit in motion.

Training includes past examples of vertical tilt, side-shift, solder ball misalignment, and package deformation, enabling the model to distinguish between acceptable and critical faults.

Each inspected unit is tagged with height maps and alignment metrics. Results are pushed into the MES for traceability, and robotic sorters are triggered to route the unit based on tolerance bins (pass/rework/fail).

Stay updated with the trending and most impactful tech insights. Check out the expert analyses, real-world applications, and forward-thinking ideas that shape the future of AI Computer Vision and innovation.

7:45AM at a busy automotive parts manufacturer. A delivery truck arrived at the dock. Usually, supervisors would take 10 minutes to scan paperwork. They’d also be keying in data. Instead, a camera quietly recorded the container ID, logged upon its arrival. And it tagged the shipment to a specific production line. All without a single […]

CEO & Co-founder

It’s 2:14 PM at a busy CFS gate. A trailer rolls in. The container is old, dusty and sun faded. The number is readable, but only if you look closely. The driver wants to move fast. The queue behind him is growing. The gate operator does what they have always done. Reads the container number. […]

CEO & Co-founder

Modern logistics depend on speed. Accuracy and visibility keep logistics moving. Across container yards and CFS hubs… teams still face blind spots. They rely on manual checks and delayed data. This leads to missed damages and inefficient movement of assets. Logistics teams can see clearly by combining cameras with computer vision. They can understand and […]

CEO & Co-founder