Lead Frame And Substrate Inspection

Inspect Before You Bond. Prevent Failure Before Assembly.

Lead frames and substrates form the physical base for semiconductor packages, any warpage, contamination, or dimensional fault at this level can cause bonding issues, electrical shorts, or total package failure. Manual inspection is inconsistent, and traditional 2D tools often miss warpage or multilayer misalignment. AI-powered Lead Frame and Substrate Inspection uses advanced 2D/3D computer vision to detect surface defects, warpage, and structural misalignment before die attach or wire bonding. With micron-level resolution and intelligent classification, the system ensures only flawless frames proceed to the next stage.

Scratches, dents, or oxidation on the lead frame surface may go undetected in visual checks, leading to bonding failure.

Substrate thickness, paddle depth, or pad spacing variations cause die misplacement or electrical mismatch.

Mechanical warpage due to improper storage or handling can cause poor die attach, especially in multi-layer substrates.

Human error and subjective judgment reduce reliability and throughput under high-volume demands.

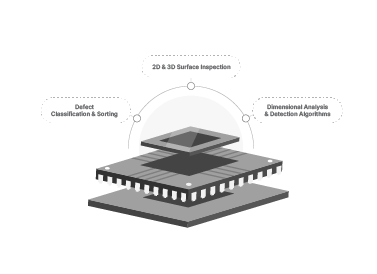

Captures surface irregularities, corrosion, scratches, and dents using high-resolution visual and depth scanning.

Measures pad pitch, bond fingers, paddle flatness, and outline dimensions against golden specs.

Uses machine vision with 3D reconstruction to detect bending or structural warpage in substrates and frames.

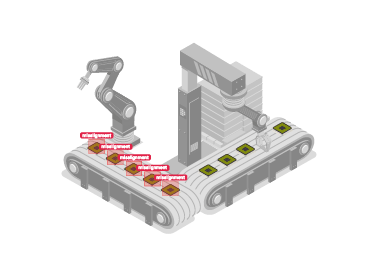

Automatically classifies defects and routes defective units to rework bins or rejects them, no operator input needed.

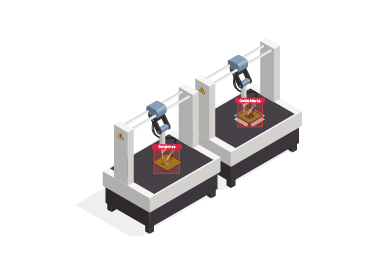

We begin by mapping the inspection point between cleaning and die attach stages, integrating the system with your substrate loader/unloader and frame handler.

Combining area-scan cameras and laser triangulation sensors, we enable full-surface and height-map acquisition for each lead frame or substrate in motion.

Our AI model is trained on real-world defect libraries from your past rejects, scratches, oxide marks, pad shifts, to achieve context-specific classification.

Inspection outcomes are sent to the MES (Manufacturing Execution System) in real time, triggering robotic sorters or binning logic to separate units by defect class or reworkability.

Stay updated with the trending and most impactful tech insights. Check out the expert analyses, real-world applications, and forward-thinking ideas that shape the future of AI Computer Vision and innovation.

7:45AM at a busy automotive parts manufacturer. A delivery truck arrived at the dock. Usually, supervisors would take 10 minutes to scan paperwork. They’d also be keying in data. Instead, a camera quietly recorded the container ID, logged upon its arrival. And it tagged the shipment to a specific production line. All without a single […]

CEO & Co-founder

It’s 2:14 PM at a busy CFS gate. A trailer rolls in. The container is old, dusty and sun faded. The number is readable, but only if you look closely. The driver wants to move fast. The queue behind him is growing. The gate operator does what they have always done. Reads the container number. […]

CEO & Co-founder

Modern logistics depend on speed. Accuracy and visibility keep logistics moving. Across container yards and CFS hubs… teams still face blind spots. They rely on manual checks and delayed data. This leads to missed damages and inefficient movement of assets. Logistics teams can see clearly by combining cameras with computer vision. They can understand and […]

CEO & Co-founder