Ladle Movement Tracking

Track molten metal movement with precision. Prevent spills, reduce risk, and enhance casting control.

In steel plants, ladles carry molten metal at extreme temperatures. Any delay, misalignment, or deviation during transfer can result in accidents, production loss, or structural damage. AI-powered Ladle Movement Tracking ensures real-time visual tracking of ladles from furnace to caster, monitoring position, speed, alignment, and stoppage. It reduces manual dependency and boosts safety during the most hazardous phase of steelmaking.

Human oversight during ladle movement is inconsistent, especially in high-heat, low-visibility areas.

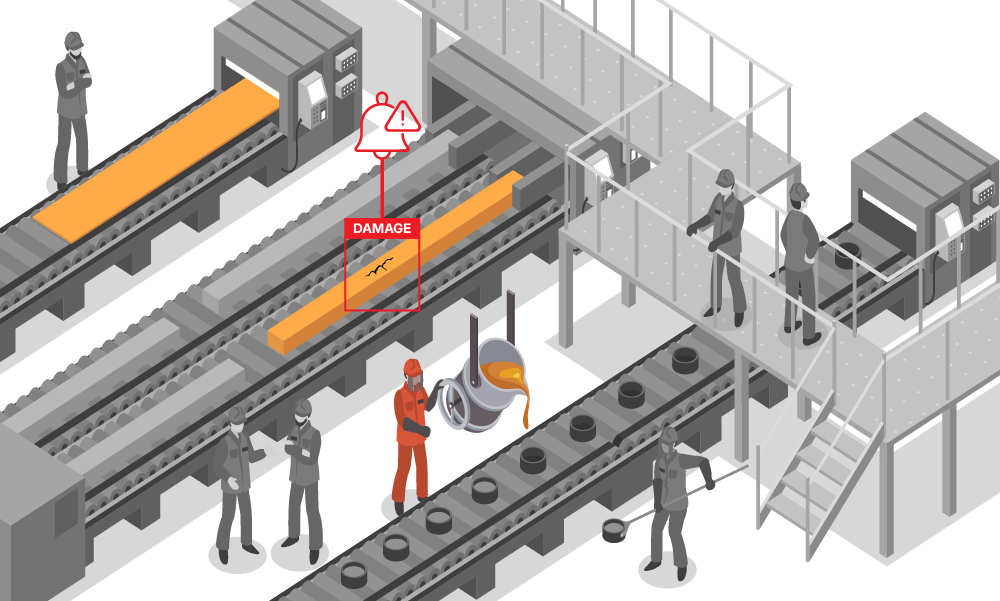

Improper ladle alignment or delay can lead to defective casting or spillage.

The area around ladle transfer is among the most dangerous, errors can be catastrophic.

No centralized way to track ladle movement from furnace to pouring station.

Constant location visibility of each ladle along transfer paths using AI-based vision.

The system notifies operators when ladles deviate from preset alignment zones.

Detects unusual speed variations that indicate mechanical issues or operator error.

Designed to function accurately under low lighting, glare, and smoky environments.

Every steel plant has unique ladle paths, from furnace, through transfer bays, to casting points. We start by mapping your ladle track layouts, transfer intervals, and critical zones (e.g., turning points, elevation changes).

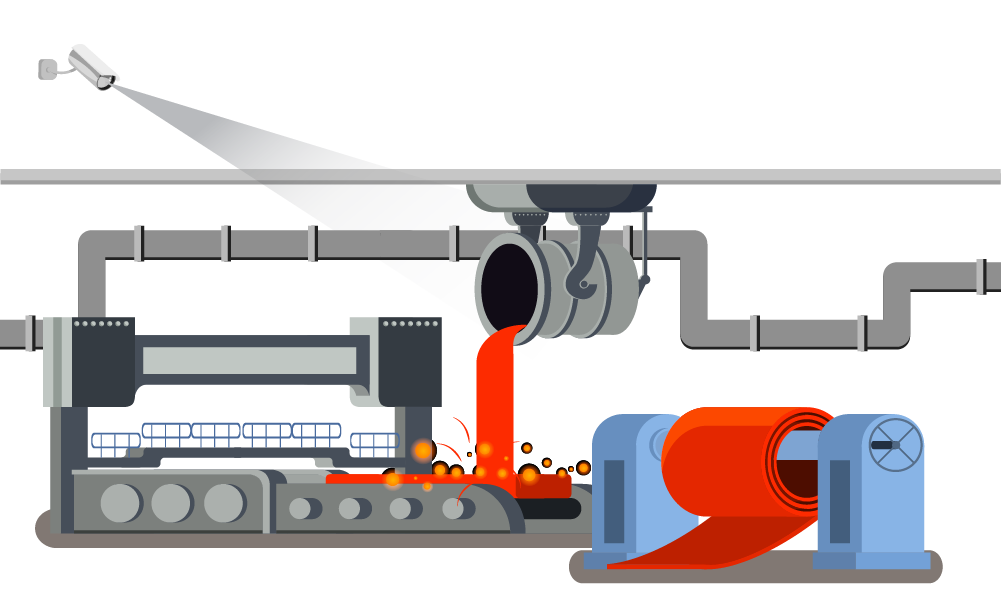

Specialized thermal-resistant cameras are placed along the route to cover overhead cranes, rail paths, and pouring bays, ensuring no blind spots in motion tracking.

We collect video data of standard vs. abnormal ladle movements (e.g., misaligned pour, idle time, speed spikes). This is used to train a motion-pattern AI model specifically for your plants environment.

The AI model is connected with your SCADA or DCS system. When unusual ladle behavior is detected (e.g., excessive vibration, drift, or delay), alerts are triggered on operator screens, with optional auto-shutdown triggers.

Stay updated with the trending and most impactful tech insights. Check out the expert analyses, real-world applications, and forward-thinking ideas that shape the future of AI Computer Vision and innovation.

7:45AM at a busy automotive parts manufacturer. A delivery truck arrived at the dock. Usually, supervisors would take 10 minutes to scan paperwork. They’d also be keying in data. Instead, a camera quietly recorded the container ID, logged upon its arrival. And it tagged the shipment to a specific production line. All without a single […]

CEO & Co-founder

It’s 2:14 PM at a busy CFS gate. A trailer rolls in. The container is old, dusty and sun faded. The number is readable, but only if you look closely. The driver wants to move fast. The queue behind him is growing. The gate operator does what they have always done. Reads the container number. […]

CEO & Co-founder

Modern logistics depend on speed. Accuracy and visibility keep logistics moving. Across container yards and CFS hubs… teams still face blind spots. They rely on manual checks and delayed data. This leads to missed damages and inefficient movement of assets. Logistics teams can see clearly by combining cameras with computer vision. They can understand and […]

CEO & Co-founder