Container OCR

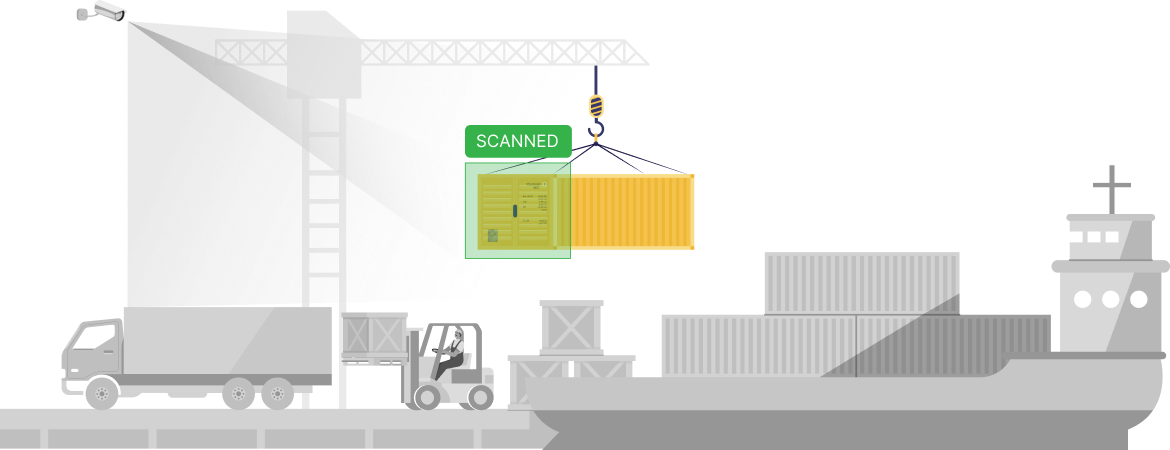

Streamline container movement, reduce idle times and boost security.

Container Code Recognition simplifies, expedites, and automates container tracking and management. Thus, making it error-free. It accurately captures and registers container codes along with the time and data. It helps manage stacked containers. It makes entry/exit faster and contributes to the safety of the depot by denying unauthorized entry to vehicles. This reinforces Port security configuration.

Manual processes often result in missed or incorrect container codes. This leads to delays and errors in the Container Tracking System.

Standard systems struggle with varied container sizes and orientations. It requires manual intervention. This limits scalability in Smart Container Management environments.

Slow identification and registration processes create bottlenecks in cargo movement by undermining the potential of container terminal automation.

Damaged surfaces, poor lighting and movement reduce scanning accuracy. This is a challenge solved with OCR-driven Container Automation.

AI OCR for Logistics ensures precise ISO code recognition by reducing human error and increasing reliability.

Seamlessly reads horizontal and vertical text. It enhances Container Identification performance across container types.

High-speed image and video analysis allows scanning of even moving containers by ensuring optimized Container Tracking System operations.

Reliable barcode reading in low-light and high-motion conditions. These ensure uninterrupted cargo flow and better inventory control.

Container OCR is beneficial for a wide range of stakeholders within the global supply chain as it transforms how goods are handled by them.

High-resolution cameras are strategically placed to capture container codes across a wide variety of entry/exit scenarios.

A diverse data set of container images is gathered and labeled to train models capable of adapting to real world variation.

Using deep learning techniques like CNN. It is a model that is trained and optimized for high precision in Container Code Recognition.

The system is deployed and integrated with existing terminal systems. That is for real-time inference and process acceleration.

Stay updated with the trending and most impactful tech insights. Check out the expert analyses, real-world applications, and forward-thinking ideas that shape the future of AI Computer Vision and innovation.

7:45AM at a busy automotive parts manufacturer. A delivery truck arrived at the dock. Usually, supervisors would take 10 minutes to scan paperwork. They’d also be keying in data. Instead, a camera quietly recorded the container ID, logged upon its arrival. And it tagged the shipment to a specific production line. All without a single […]

CEO & Co-founder

It’s 2:14 PM at a busy CFS gate. A trailer rolls in. The container is old, dusty and sun faded. The number is readable, but only if you look closely. The driver wants to move fast. The queue behind him is growing. The gate operator does what they have always done. Reads the container number. […]

CEO & Co-founder

Modern logistics depend on speed. Accuracy and visibility keep logistics moving. Across container yards and CFS hubs… teams still face blind spots. They rely on manual checks and delayed data. This leads to missed damages and inefficient movement of assets. Logistics teams can see clearly by combining cameras with computer vision. They can understand and […]

CEO & Co-founder