CMP Quality Monitoring

Perfect the Planarity. Catch Surface Irregularities Before They Cost You Yield.

Chemical Mechanical Planarization (CMP) is critical for achieving flat surfaces before lithography and metalization layers, but it’s also one of the most defect-prone processes in semiconductor fabrication. Microscopic erosion, dishing, scratches, and thickness variations can easily go undetected until later stages, causing metal bridging, poor pattern fidelity, and electrical faults.

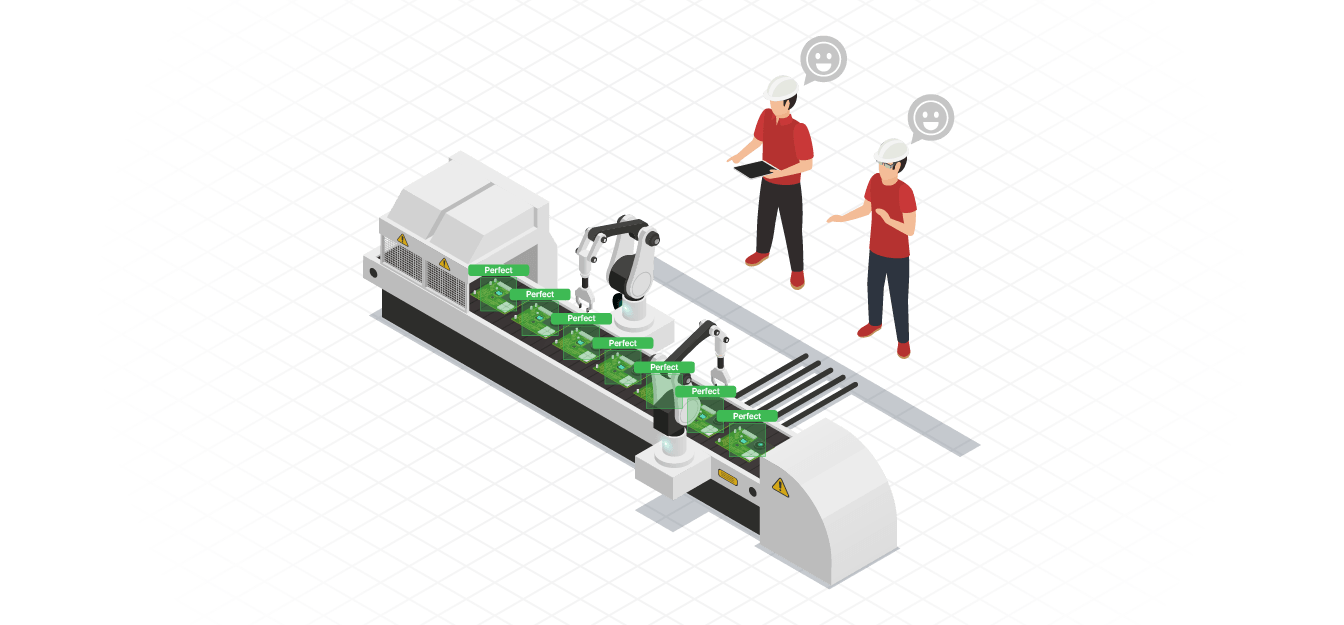

AI-powered CMP Quality Monitoring systems use real-time computer vision and surface profiling to inspect wafers for planarity issues, pattern distortions, and mechanical damage, before wafers exit the CMP tool.

Surface depressions or raised areas often escape detection using static metrology tools.

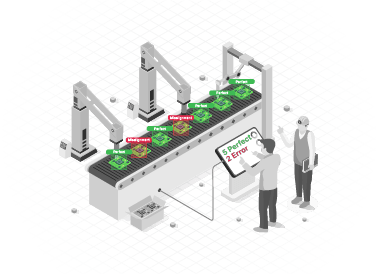

By the time defects are caught, wafers have already moved forward, resulting in batch-level loss.

Traditional CMP lacks intelligent automation for adjusting pad pressure or slurry flow in real time.

Edge vs. center planarity variations often go undiagnosed without full-field visual inspection.

Vision systems detect topography variations like dishing, erosion, and micro-scratches as wafers exit the platen.

Full-wafer visual analysis to ensure uniform thickness across all regions.

AI detects and classifies CMP-related defects using training data, reducing false positives.

Detects trends in pad wear or slurry issues and feeds data back to adjust process settings.

We begin by auditing your specific CMP tools, single or double platen, and defining inspection points for incoming and outgoing wafers.

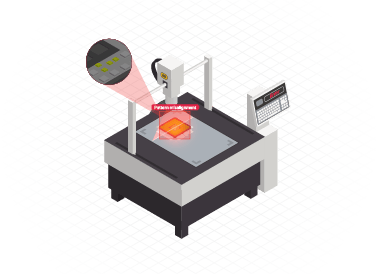

High-speed line-scan or area-scan cameras are calibrated for low reflectivity surfaces, mounted above wafer exit conveyors with optical flattening filters to reduce glare.

AI models are trained using thousands of annotated wafer images to recognize surface artifacts like microscratches, pad marks, and planar deviations with high accuracy.

The system is integrated directly into the CMP tool’s output lane or post-clean module, providing instant alerts for abnormal surface profiles and enabling dynamic process correction without production delay.

Stay updated with the trending and most impactful tech insights. Check out the expert analyses, real-world applications, and forward-thinking ideas that shape the future of AI Computer Vision and innovation.

7:45AM at a busy automotive parts manufacturer. A delivery truck arrived at the dock. Usually, supervisors would take 10 minutes to scan paperwork. They’d also be keying in data. Instead, a camera quietly recorded the container ID, logged upon its arrival. And it tagged the shipment to a specific production line. All without a single […]

CEO & Co-founder

It’s 2:14 PM at a busy CFS gate. A trailer rolls in. The container is old, dusty and sun faded. The number is readable, but only if you look closely. The driver wants to move fast. The queue behind him is growing. The gate operator does what they have always done. Reads the container number. […]

CEO & Co-founder

Modern logistics depend on speed. Accuracy and visibility keep logistics moving. Across container yards and CFS hubs… teams still face blind spots. They rely on manual checks and delayed data. This leads to missed damages and inefficient movement of assets. Logistics teams can see clearly by combining cameras with computer vision. They can understand and […]

CEO & Co-founder