WebOccult Insider | July 25

Ruchir Kakkad

CEO & Co-founder

Meet the mascots who will break down complex AI Vision into clear, simple stories.

There’s a new pair of minds at work inside WebOccult’s AI Vision ecosystem, and they don’t blink, miss, or guess. Say hello to nAItra & nAIna, the official mascots of WebOccult’s AI Vision division.

But don’t let their sharp design and clean lines fool you, these two are not just for show.

Built on a foundation of real-time analytics, deep learning, and computer vision, nAItra and nAIna represent the intelligence that powers every smart decision our systems make.

From tracking cargo at busy ports to detecting facial patterns in high-traffic areas, if your cameras see it, they understand it, accurately and instantly.

Whether it’s real-time object tracking, facial recognition, container OCR, or behavioural analytics, these two are here to explain how AI Vision is changing the way the world monitors, secures, and operates its environments. Through their voices, we’ll break down complex use cases into clear, simple insights, because vision tech should never feel like a black box.

This is just the beginning. Starting this month, nAItra & nAIna will be a regular presence across our channels, unpacking use cases, sharing behind-the-scenes tech, and helping you see AI through a smarter lens.

Stay tuned. The future of intelligent vision now has a face, actually, two.

A few months ago, in one of our internal brainstorms, someone casually said, “Our AI Vision systems are so sharp, they almost feel alive.” That sentence stuck with me. Not because of how smart the tech is but because it made me realize something important: people don’t connect with specs, they connect with stories.

That’s how nAItra & nAIna were born.

They aren’t just mascots. They’re here to represent the intelligence behind our systems, the way we think, and the way our technology helps businesses see, better and faster. Through them, we’re simplifying how we talk about complex things like real-time tracking, facial recognition, and container OCR. Because if the tech is powerful but no one understands how it works or helps, what’s the point?

As we move forward, our focus is sharper than ever.

We’re now doubling down our focus on two industries where every second, every scan, and every decision counts: Ports and the Steel Industry.

Ports deal with overwhelming cargo volumes, tight schedules, and zero room for manual errors. Our AI Vision is already helping streamline container movement, reduce idle time, and prevent unauthorized access, with precision and speed.

In the steel industry, the challenges are different but just as critical. Heat, heavy movement, safety risks, there’s no space for delay. Our AI Vision is now being trained to detect micro-defects, track ladle movement, and monitor safety conditions without disrupting operations.

This is what excites me, not just building tools, but building clarity. Giving industries a smarter way to operate.

A few weeks ago, I found myself at a railway station, waiting for my train to my native home. Between sips of coffee and glances at arrival boards, I watched a small team of platform staff manually checking tickets, scanning IDs, and jotting notes on paper.

It struck me- in an era where people move faster than paperwork, something as simple as boarding a train still follows old routines.

That afternoon, I sketched a vision. What if AI Vision could modernize this scene? Install cameras to automatically scan QR tickets, detect mismatches, and alert guards to safety or scheduling issues, all in real time. No more lines. No more errors. Just a powerful flow.

Can we apply touchless OCR technology to passengers? Can we train a model to understand crowd movement like we track cargo lanes? Turns out, yes.

By adapting our multi-angle OCR and behavioral-tracking pipelines, we can build a prototype that reads digital tickets at speed and flags irregularities, bright stations, quiet waiting rooms, and everything in between.

That evening, as the train rolled in, I realized the metaphor: just like a train departs precisely when it’s ready, so does progress.

Sometimes innovation comes not in labs but in transit, in fields, in everyday gaps waiting for smarter vision.

“People worry that computers will get too smart and take over the world, but the real problem is that they’re too stupid and they’ve already taken over the world.”

Melanie Mitchell, Artificial Intelligence: A Guide for Thinking Humans

This month’s reflection isn’t about the usual fear of AI becoming too powerful, it’s the quiet irony of how often it’s already steering our world with astonishing missteps. From algorithmic biases deciding who gets a loan to flawed image recognition tagging the wrong person, AI is everywhere, but not always wise.

At WebOccult, we see this clarity as a guiding principle. AI Vision isn’t about flashy tech, it’s about trust. Our models learn nuances like lighting, context, edge cases, so they make fewer mistakes, not just more decisions. We’re less interested in teaching machines to think like us, and more in making sure they don’t misunderstand us.

So when you next hear about the AI revolution, remember: the real breakthrough isn’t about intelligence that matches ours, it’s about intelligence that complements ours.

And in that space, there’s elegance in being deliberately less stupid.

Smit Khant, Sales Director, USA

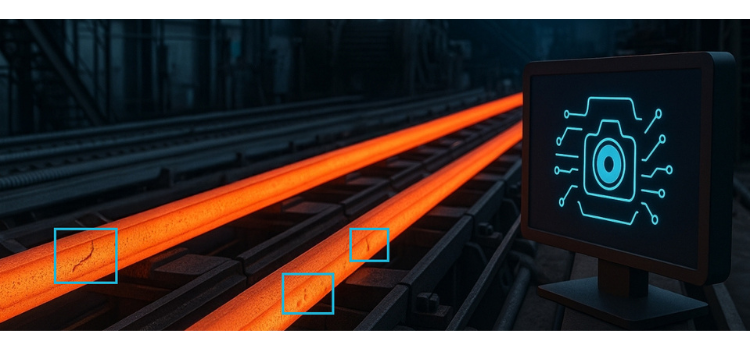

When I stepped into the hot, humming heart of a Midwest steel plant last spring, I expected loud machines and focused workers. What surprised me was the atmosphere of quiet precision, cameras strategically positioned, and AI models running silently in the background, inspecting each slab of steel with uncanny accuracy.

Our recent blog outlines a powerful shift in 2025’s steelmaking strategies. But seeing it in action drives the point home: traditional inspections, manual, inconsistent, prone to fatigue, are being replaced by AI Vision systems that never blink.

At that plant, high-resolution cameras trained by deep-learning models like Vision Transformers analyzed every slab for micro-cracks, rust patches, and surface anomalies. These cracks, nearly invisible to the human eye, were flagged instantly, reducing defect rates by over 20%. When issues arise, alerts go out immediately, ensuring no faulty steel leaves the mill.

But AI Vision isn’t just policing quality, it’s optimizing operations and boosting sustainability. Our systems monitor furnace heat distribution and chemical balances in real time, automatically adjusting parameters to improve output consistency while reducing energy use by 5–7%.

Across plants, this translates to significant fuel savings and lower emissions, a win for both the balance sheet and the environment.

AI Vision has also become a cornerstone of predictive maintenance at these facilities. Cameras paired with thermal sensors and vibration analysis spot potential equipment failures well before breakdowns occur. One recent deployment flagged an overheating turbine bearing that, if overlooked, would have cost over $500,000 in repairs. Instead, maintenance was scheduled proactively, and downtime was minimized.

In the USA, steel manufacturers are more than ever embracing this visual intelligence as a strategic asset. AI Vision isn’t simply a tool; it’s becoming the eyes of plants, detecting quality issues, ensuring smooth operations, preventing costly breakdowns, and helping reduce environmental footprint.

If you lead steel operations and haven’t yet considered integrating AI Vision into your quality, energy, or maintenance pipelines, now is the time. I’d be glad to walk you through pilot options and share outcomes we’ve already delivered in American plants.