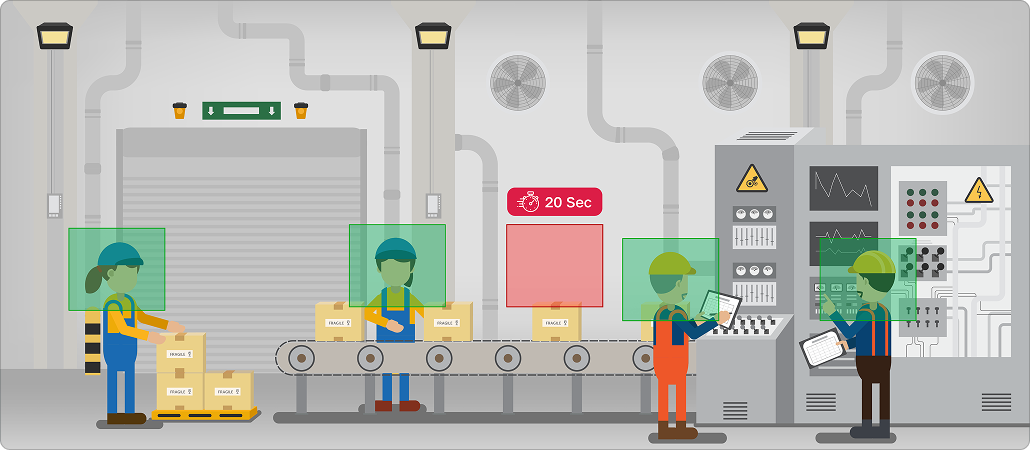

GOTILO INSPECT

Precise Inspection, Consistent Quality

Gotilo Inspect is an AI Inspection System that brings accuracy to manufacturing lines by detecting defects through Automated Defect Detection, verifying product standards and supporting quality control in real time. With structured analysis and automated checks using a Visual Inspection System, it helps reduce rework, ensure consistency and maintain stable production outcomes as a reliable Manufacturing Quality Control System.

Download Brochure