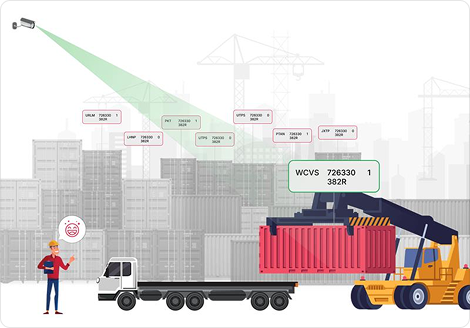

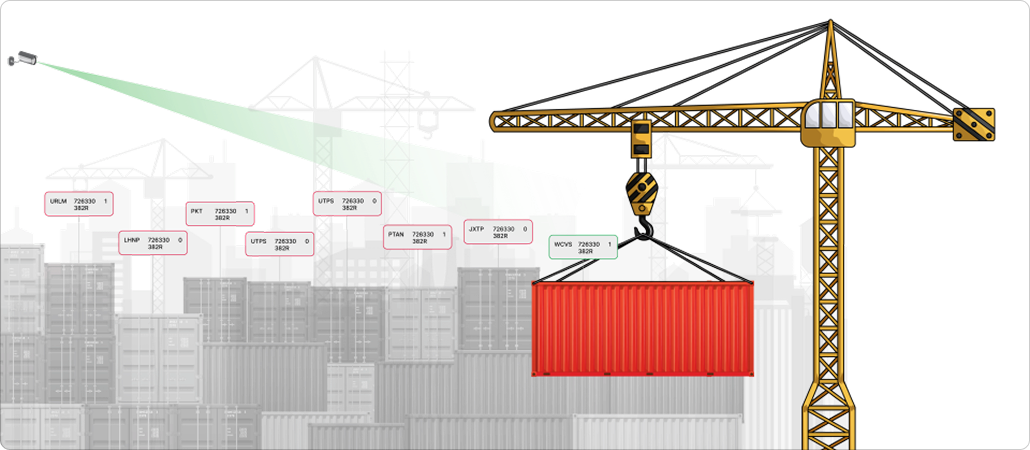

GOTILO CONTAINER

Reliable Logistics, Steady Control

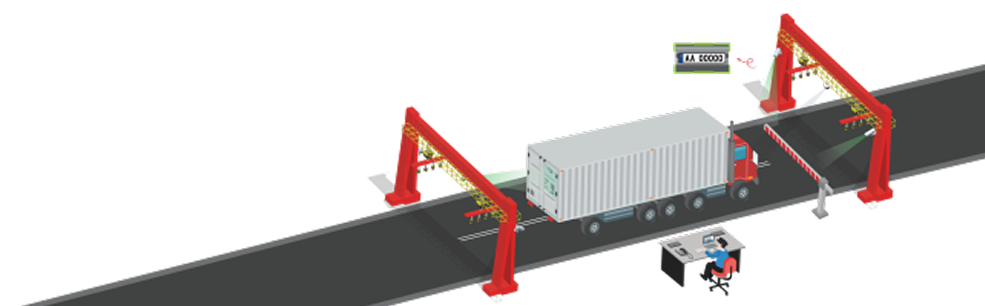

Manage containers with optical recognition through a Container OCR System, yard automation via a Container Yard Management System and real-time visibility using Container GeoLocation Tracking to reduce delays, lower costs and maintain smooth movement across the supply chain with a Container Gate Automation System.

Download Brochure