Gotilo Vision

See Beyond Vision. Act Faster. Safer.

Practical AI vision in that spots risks, ensures quality, and streamlines container flow through the Gotilo Platform, keeping your operations sharp and future-proof.

Explore Demo

Even with digital adoption on the rise, many industries still struggle with workplace safety, quality consistency, and container management due to outdated manual checks without a unified Gotilo AI Platform. Frontline teams lack real-time tools to prevent incidents, catch defects early and streamline tracking across a Computer Vision Logistics Platform by exposing businesses to costly risks and downtime.

Of workers report that a safety incident occurred in their workplace in the past 12 months.

Of all workplace injury and illness cases involved employees who had been on the job for a year or less

Of manufacturers report that their production, quality control, and supply chain systems don’t fully integrate.

Gotilo products support frontline teams by providing clear, real-time information on safety, quality, and logistics through a centralized Logistics Automation Platform. This allows workplaces to remain secure, consistent and efficient.

With Gotilo Spot, supervisors can observe worker activity in real time, confirm protective equipment use, identify risks promptly, and maintain a safer environment.

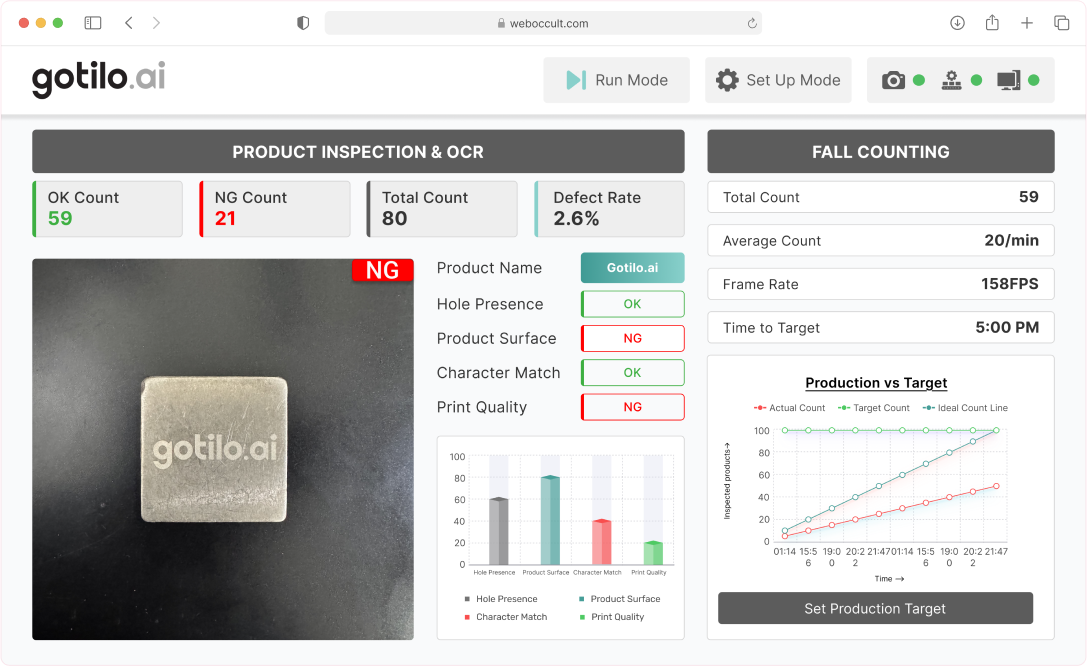

Gotilo Inspect automates inspection tasks, identifies faults at an early stage, reduces the need for rework, and helps sustain product standards.

Gotilo Container applies optical recognition and tracking to simplify yard management, prevent delays, and improve the flow of goods.

Gotilo products bring together worker protection, defect monitoring, and container management as part of a unified Container, Inspection & Yard Automation approach to support efficient and reliable industrial operations.

Observe workforce activity in real time using the Gotilo Platform. Identify unsafe practices, confirm compliance with safety rule, and lessen risks through informed oversight.

Reduce manual error through automated checks powered by the Gotilo AI Platform. Detect faults early, maintain consistent quality and uphold standards of assurance.

Use optical recognition and yard automation within a Computer Vision Logistics Platform to follow containers, reduce paperwork and improve the flow of goods.

Combine data sources in one view through a single Logistics Automation Platform. Gain clear reports, make timely decisions and strengthen control of industrial processes.

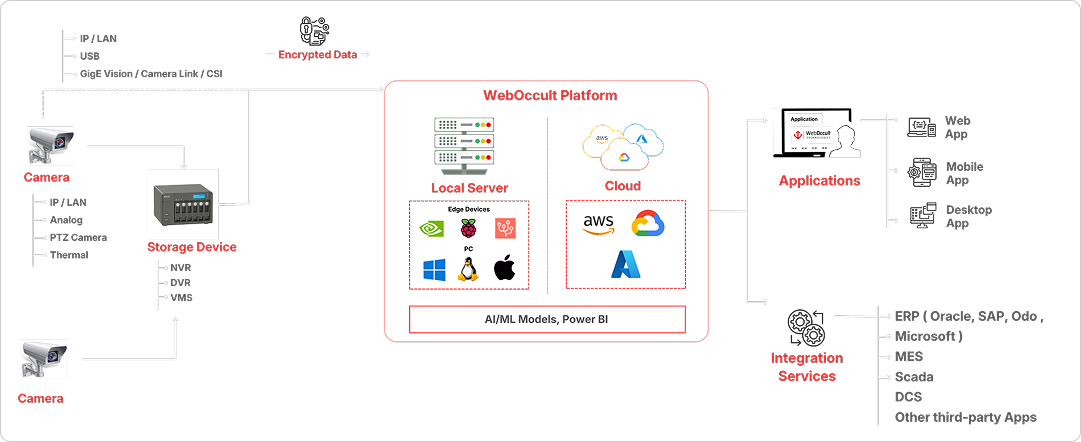

WebOccult converts video streams into practical intelligence by linking on-site servers, cloud systems, and trained models with straightforward application and integration.

The Gotilo Platform is an AI-powered vision platform that brings together safety monitoring, quality inspection and container intelligence in a single system to help industrial operations run more efficiently and reliably.

Gotilo offers solutions for worker safety and compliance, automated defect detection and quality inspection, and container tracking and yard automation to support end-to-end industrial operations.

The Gotilo Platform is designed for manufacturing units, logistics hubs, warehouses, ports, industrial yards and enterprises that require real-time visibility, automation and operational control.

Yes. Gotilo is built to support both logistics and manufacturing environments by improving safety. This ensures consistent quality and streamlining container and yard operations.

Gotilo improves operational efficiency by replacing manual checks with real-time monitoring, early issue detection and unified insights. This is possible by helping teams reduce downtime, prevent errors and make faster, data-driven decisions.