Customer

One of the Top 5 Steel Manufacturing Company in Japan

Project Details

- Duration: 3 Months+

Technologies:

- Deep Learning

- OpenCV

- PyQt

- Matplotlib

- SQLite

One of the Top 5 Steel Manufacturing Company in Japan

Technologies:

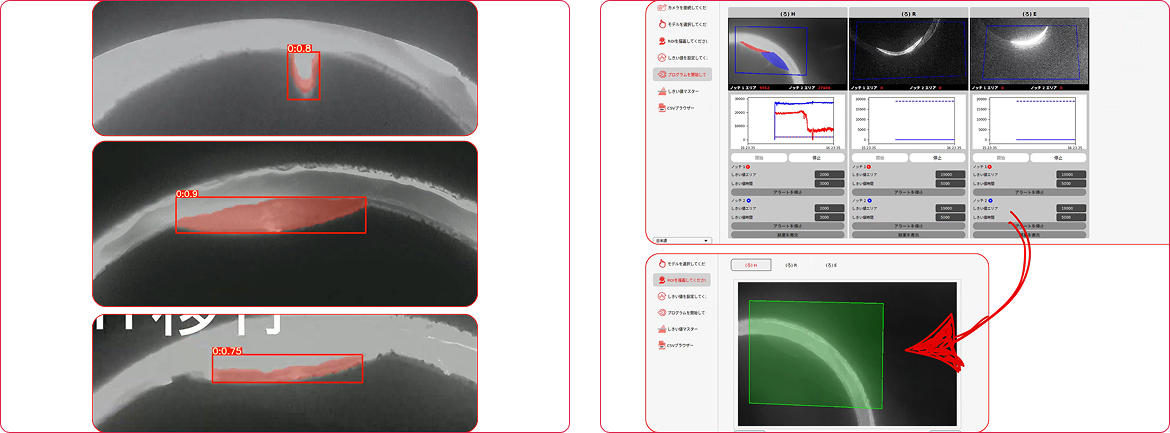

As the load cells are not installed in some furnaces, visual monitoring is performed by the operator.

We have designed a Desktop Application that performs the detection on the depleting area (Notch).

The Outcome: It is working with high accuracy, giving precise results and timely alerts.

Stay updated with the trending and most impactful tech insights. Check out the expert analyses, real-world applications, and forward-thinking ideas that shape the future of AI Computer Vision and innovation.

Walk into a semiconductor fabrication plant in 2025 and you’ll see something that looks more like a science fiction set than a factory. Robots glide across spotless cleanrooms, wafers are carried through vacuum-sealed chambers, and machines whisper in precision rhythms. Each wafer that enters the fab is a canvas on which billions of transistors will […]

CEO & Co-founder

Semiconductor fabrication plants, commonly called fabs, are some of the most complex and expensive factories ever built. Inside cleanrooms that are thousands of times cleaner than a hospital operating room, wafers of silicon are transformed into chips that power the world’s smartphones, cars, medical devices, and satellites. Every wafer goes through hundreds of steps, lithography, […]

CEO & Co-founder

Every chip in your phone, your laptop, or even in a satellite, begins as a plain slice of silicon. But before that slice can become the heart of advanced electronics, it has to go through a series of complex processes. One of the least understood, yet most critical of these, is called Chemical Mechanical Planarization, […]

CEO & Co-founder