Reducing Lost Containers in Yards – The Role of Computer Vision

Ruchir Kakkad

CEO & Co-founder

Modern container ports handle immense volumes of cargo, moving millions of containers through their yards each year. Amid this scale, even a tiny fraction of misplaced containers can cause significant operational losses. A lost container in the yard, typically one put in the wrong slot or recorded incorrectly, can cause shipping delays, extra labor, and economic losses.

In this blog, we explore how computer vision technologies, especially AI-powered cameras mounted on container handling equipment like Kalmars, are reducing container misplacement in port yards.

In the fast-paced port yard, misplaced containers are more common than one might think. If inventory accuracy even slips by a tenth of a percent, the impact is huge at scale.

For instance, the worlds busiest port, Shanghai, handled about 47.3 million TEU in 2022, if just 0.1% of those containers were lost or mis-placed, that would mean over 47,000 containers missing in a year. Each misplaced container is not just a needle in a haystack, its like a domino that can disrupt operations.

When a container isnt where the manual system thinks it is, cranes and trucks are forced to wait, reducing productivity. In worst cases, a vessel may have to depart without loading a container that cant be located in time, a costly failure in customer service.

Misplaced containers trigger a snowball effect in the yard. It often starts with a simple logging error: a driver might place a container in the wrong slot and hit OK on the terminal operating system, unaware of the mistake. The TOS now has incorrect location data. When another container is later assigned to that same slot (unaware its already occupied), the driver finds it blocked and must improvise, perhaps putting the container in an alternate spot.

If they dont report this deviation, one misplaced container leads to others, as each subsequent move happens into further exceptions. Over time, such floating containers, present in the yard but not where theyre supposed to be, accumulate, decreasing yard inventory accuracy.

![]()

Why do containers get misplaced in the first place? Traditional yard management face several challenges that open the door to human error and chaos:

In summary, traditional yard management is a juggling act of people and machines with limited technology support.

When a container goes missing in the yard, the consequences reverberate through port operations and beyond:

Artificial intelligence (AI) and computer vision technologies are addressing the very root causes of container misplacement. By leveraging cameras, sensors, and smart algorithms, modern ports can automatically track container movements with minimal human input.

One breakthrough is mounting AI-powered cameras directly on container handling equipment, for example, on the spreaders of reach stackers, RTG cranes, or straddle carriers (including popular brands like Kalmar). These rugged cameras watch each container as it is lifted, moved, and stacked, enabling real-time identification and location tracking.

A prime example is Kalmars recently introduced smart system. Cameras on the spreader scan the containers external markings to read its unique ID number, and the system automatically relays this to the Terminal Operating System. The moment a driver picks up a container, the AI vision cameras confirm which container it is and, thanks to integration with yard geo-positioning systems, logs exactly where its being placed. This achieves two things: it eliminates manual data entry and it provides continuous, up-to-date inventory records in the TOS.

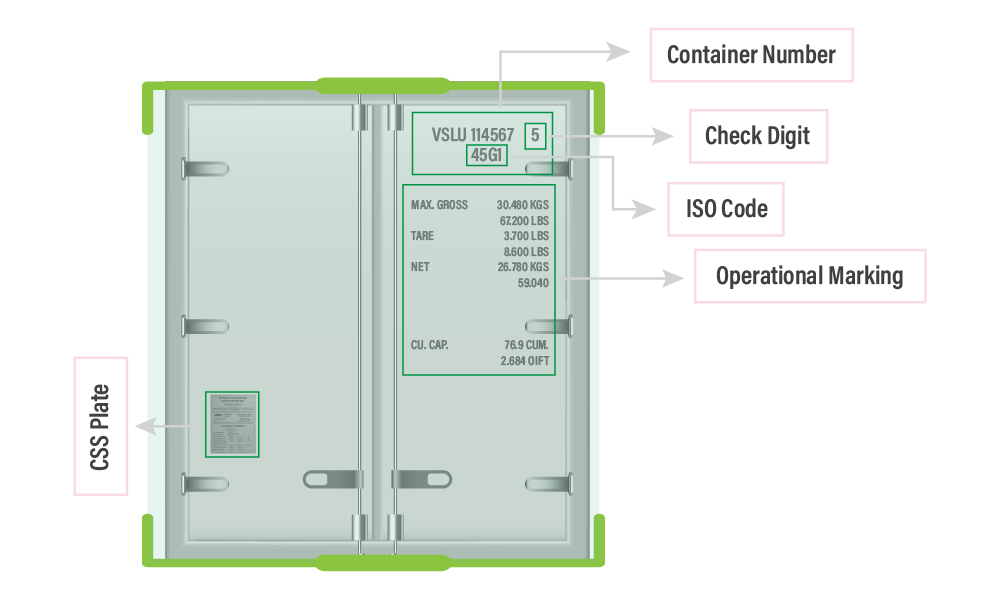

At the heart of these vision systems is Optical Character Recognition (OCR), which enables computers to read the alphanumeric codes on each container. Every shipping container has a unique identification code (four letters followed by seven numbers, e.g. ABCD1234567). Reading these correctly is vital to tracking containers.

Traditionally, a human clerk or driver might jot down or manually key in this code at various checkpoints, a process that tends to make mistakes. OCR technology automates this by using image analysis to instantly recognize the container code, even if its in tricky orientations or conditions.

Modern container OCR is remarkably accurate and fast. For example, solutions provided by firms like WebOccult achieve ISO container code recognition rates exceeding 99%. These systems are trained on thousands of container images, learning to handle different fonts, orientations, varying lighting, and even partially damaged numbers. The result is that, in real operational settings, manual container identification errors that could be as high as 2030% have dropped to less than 1% with automated OCR.

Beyond just tracking containers, AI is also tackling how and where containers should be stacked in the first place. One reason containers get lost or require extra moves is suboptimal stacking, for example, an import container that a truck will pick up tomorrow ends up buried under five others that wont move for a week. AI can help prevent such situations through intelligent yard planning and predictive stacking.

Imagine a system that knows, or can reliably predict, when each container in the yard will likely be picked up or needed. AI makes this possible by analyzing patterns and data such as trucking schedules, vessel ETAs, customs clearance statuses, and historical trends. Using this information, the AI can forecast which containers will be needed soon and ensure they are placed in more accessible positions.

The benefits of AI-powered stacking are significant:

Forward-looking ports around the world have started reaping the benefits of AI and computer vision in their yards. Lets look at a few real-world examples that highlight the impact:

Jawaharlal Nehru Port (JNPT), India

As Indias busiest container port (~6.35 million TEU in 2022), JNPT is also upgrading its yard management with modern tech. The port has implemented an RFID-based container tracking system and is now moving toward greater automation.

In 2025, JNPT invited bids to develop an automated empty container yard with an Automated Storage and Retrieval System (ASRS) and real-time container location mapping. This planned smart yard will incorporate OCR-based gate automation and a terminal operating system capable of pinpointing every empty containers position. The goal is to eliminate the prevalent issues of yard inventory mismatch and improve turnaround times for empties. Even before this, JNPTs use of RFID tags on containers has helped reduce dwell times by giving authorities better visibility into container movements. By investing in these solutions, JNPT aims to enhance efficiency and avoid the kind of chaotic yard scenarios that lead to lost containers.

Mundra Port, India

Mundra, Indias largest private port, provides a striking example of the benefits of AI-enabled operations. By integrating AI across its logistics, from berth scheduling to yard planning, Mundra achieved over 25% improvement in cargo handling efficiency and significantly shorter turnaround times.

One contributor to this is the use of AI-powered control towers and predictive analytics to synchronize every movement. While the headline here is overall speed, a big part of that is smoother yard workflow, containers are where they need to be when they need to be. Mundras adoption of AI-driven OCR and automation at gates and yard equipment (including likely collaborations with tech firms for smart camera systems) has reduced human errors and virtually done away with lost container incidents. The ports performance is now a case study in how smart infrastructure can transform operations in South Asia. Adani Ports (which operates Mundra) reported handling 8.6 million TEU across its ports in 202223, with Mundra alone contributing ~6.6 million TEU. Keeping track of such volumes is impossible with manual methods, but Mundras success shows it can be done with AI, securely and efficiently.

Adopting AI-powered computer vision in the container yard isnt just about technology for technologys sake, it directly addresses the long-standing pain points of yard management. By reducing lost containers and improving accuracy, ports unlock a cascade of positive effects: quicker ship turnarounds, lower operating costs, safer working conditions, and happier customers. In an industry where margins are thin and schedules tight, these gains are transformative.

Ready to Transform Your Container Yard? AI vision technology can dramatically improve yard management by reducing errors and boosting throughput. To learn how you can implement AI-powered camera systems and OCR in your port or terminal, consider reaching out to experts in the field. WebOccult, a provider of advanced AI vision solutions for smart yards, can help design and deploy a tailored system that brings these benefits to your operation.

By adopting the right technology today, ports can ensure that lost containers become a thing of the past, and that their yard stays efficient, secure, and ready for the future.