How Computer Vision Is Revolutionising Quality Control in Manufacturing

Ruchir Kakkad

CEO & Co-founder

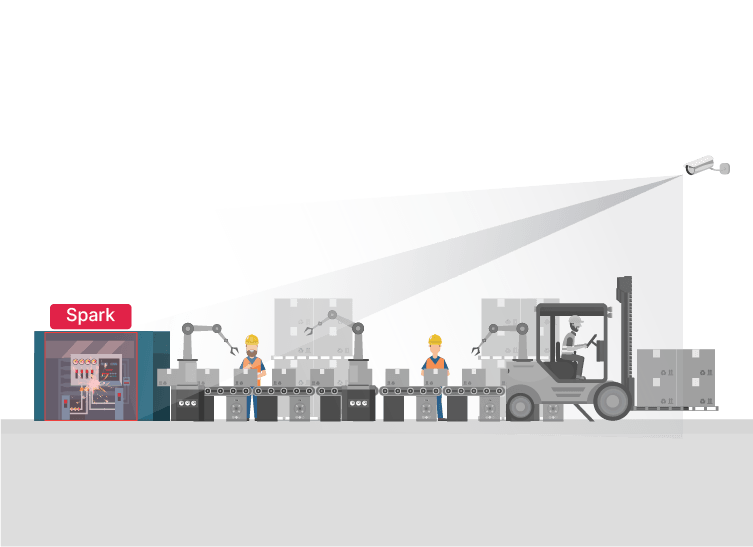

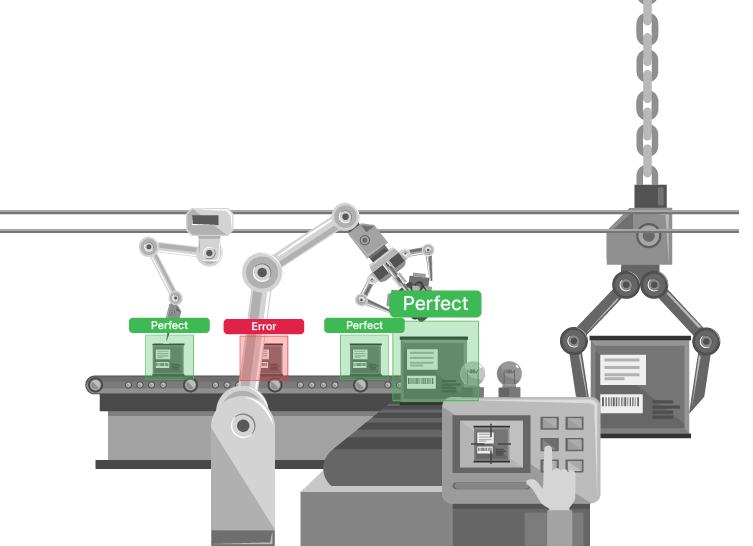

When we discuss the ways to improve quality in factories today, one solution that often comes up is Computer Vision in manufacturing. Supervising a production line makes it clear how easily small issues can go unnoticed. A small crack, a misplaced center label, or a missing screw may seem irrelevant, but these small problems can interrupt the flow of production. Even minor faults like these can cause delays or lead to a whole batch being rejected, resulting in waste of both time and money. This is where modern vision tools are changing the way factories operate. Think of them as extremely consistent “extra eyes” that never get tired and don’t miss the small stuff.

For years, quality checks were mostly manual. Someone looked at the part, judged whether it was good enough, and passed it along. That still happens today, but production speeds have increased so much that human checks alone can’t keep up. The newer shift toward Manufacturing AI quality control systems comes from a practical need: Factories want fewer surprises, fewer delays, and fewer defective products reaching customers. Vision tools help them see what’s happening on the line at every second instead of finding out about problems at the end of the shift.

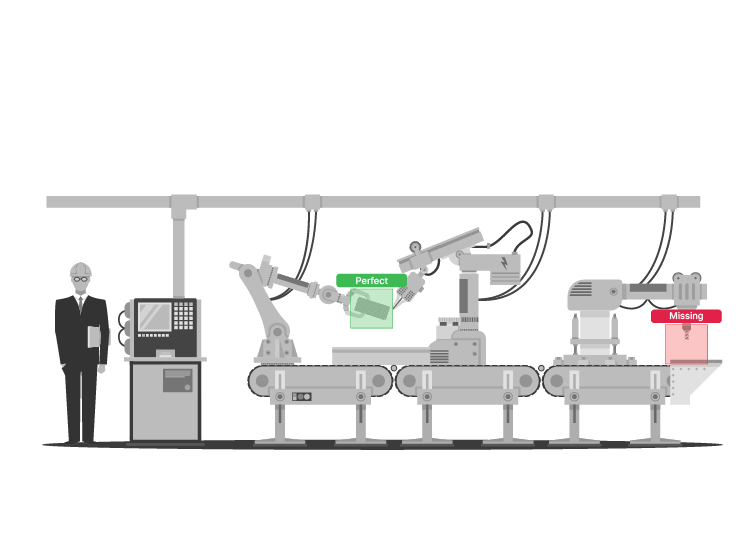

If you were explaining Control Automated Inspection to someone on your team, you would probably describe it like this: “It’s a setup that watches every product as it moves and flags anything that doesn’t look right.” That’s really all it is. The system checks things like:

These are usually helpful for tasks that are repetitive and a burden on the human eye. For instance, one can hire people to inspect solder joints in electronic items and identify metal parts, but it might be stressful and inconsistent. This is where Defect detection using AI comes in. The tool learns what a correct part looks like and alerts the team when something starts drifting from normal. That early warning often prevents a bigger issue later.

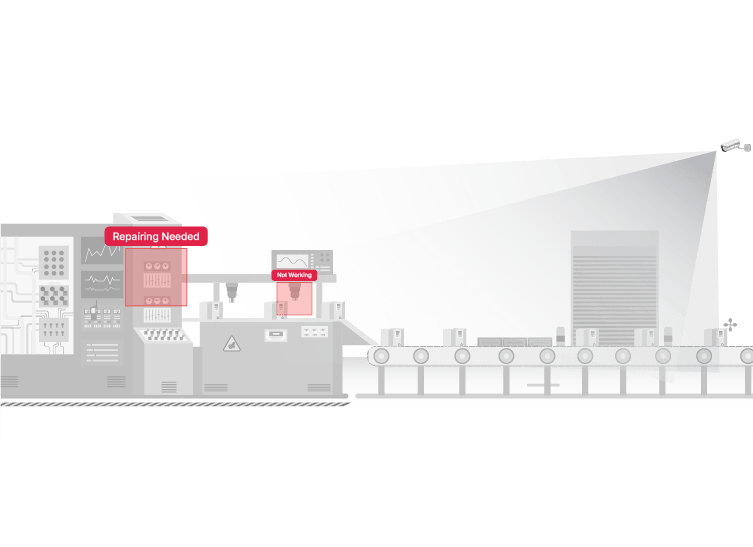

Another major benefit is how these tools help with Manufacturing automation. Once the vision system notices a pattern, say, a filler is dispensing too much product or a cutter is drifting, it can notify the machine or the operator right away. Some systems even adjust automatically. This kind of feedback loop means:

This is a big improvement compared to waiting for operators to spot problems manually. A lot of companies now combine vision checks with, so supervisors can see how the line is behaving moment by moment. It’s like having a dashboard that shows not just numbers, but real conditions on the shop floor. Production line monitoring

If you look at where factories are using Machine vision systems today, the list keeps growing. Some common uses include:

These tasks may sound simple, but they become powerful when done across thousands of items per hour with zero inconsistency. That’s where the value is.

Over time, computer vision systems do more than just spot defects. They help the whole production process run more smoothly. As these systems get better, they start working alongside other parts of the factory. For example, they help manage materials and keep track of machine performance. This allows factories to see the bigger picture. With all the information in front of them, they can make smarter decisions. This results in a process that’s not just faster but more efficient. And that means less wasted time and energy.

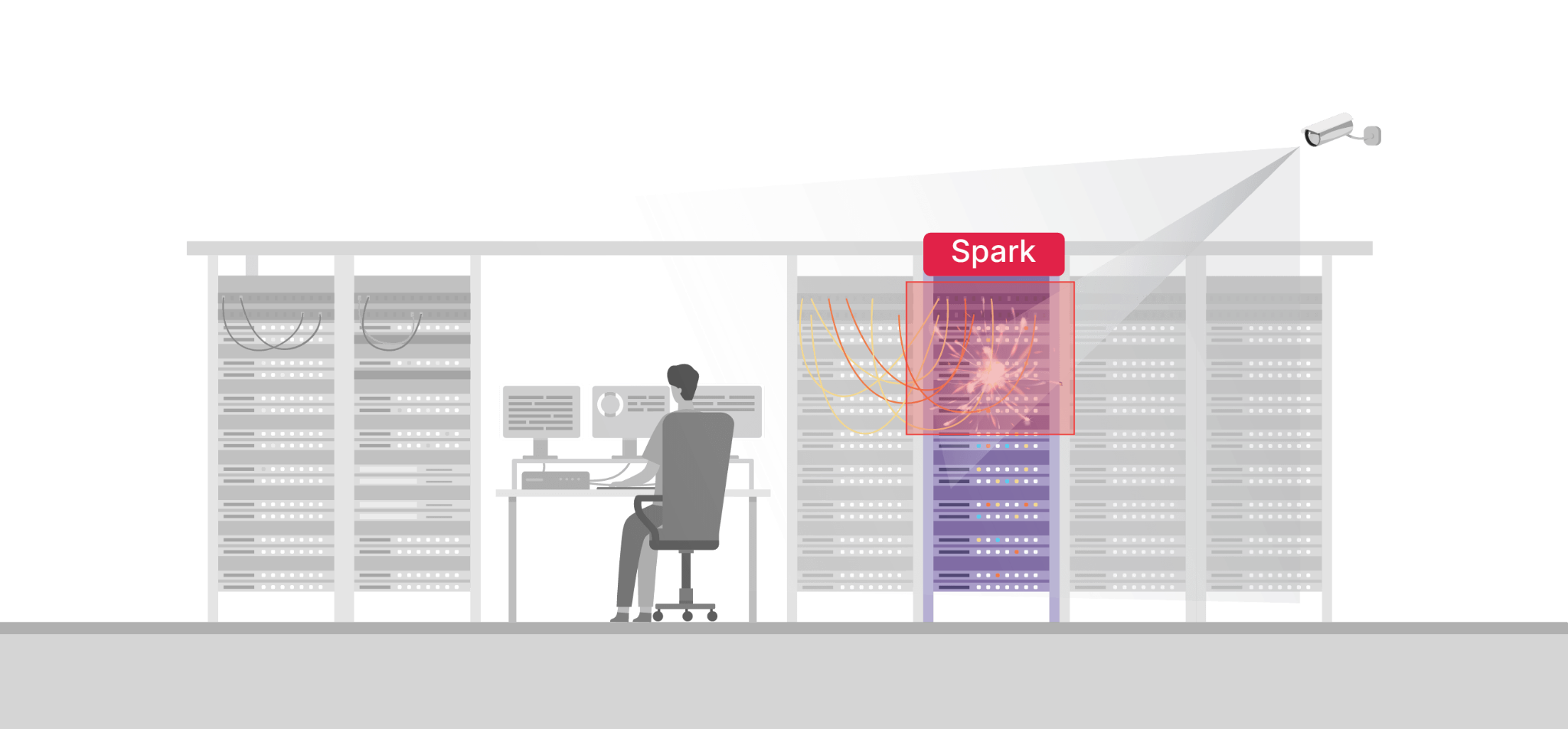

One point many people don’t realize is that vision tools also improve worker safety, like detecting machine malfunctions, or monitoring if everyone is wearing gloves, glasses, and a helmet, etc. This level of visibility prevents accidents and downtime. Many factories already treat these safety checks as part of their Industrial AI solutions rather than a separate system.

Today’s customers expect more than ever. They want products that look good, work properly, and arrive quickly. Because of that, companies don’t get much room for error. In a global market where every brand is trying to stand out, even one defective product can hurt sales and damage trust.

This pressure is even higher in industries like automotive, electronics, and food. In these areas, a small defect isn’t just an inconvenience; it can be unsafe.

For a long time, factories depended on people checking items by hand. That worked when production was slower, but it simply isn’t enough anymore. With the speed and volume of modern manufacturing, manual checks can’t keep up.

This is where computer vision helps. It makes sure every item meets the same standard, no matter how fast the line is moving. That consistency keeps companies competitive and helps them maintain customer confidence.

With these tools in place, manufacturers can keep quality high, cut down on mistakes, and move faster without lowering their standards.

One of the most useful things about modern vision systems is that they improve over time. The more they’re used, the better they get at spotting issues.

When new kinds of defects start appearing on the line, as they often do, the system can learn to recognize them. It adjusts its understanding and becomes more accurate as it goes. That means fewer problems slipping through and fewer surprises later in production.

Unlike human inspectors, who can get tired or distracted after a long shift, these systems stay sharp. And with each batch they inspect, they grow more reliable. Over time, this makes the whole production process more stable and efficient.

As helpful as vision systems are, they still need skilled people to run them. Many companies are now realizing that their teams must be ready to work with this technology, not just stand beside it.

Workers need to understand how to monitor the system, adjust it when something looks off, and make sure it’s identifying defects correctly. The tools behind these systems have to be trained, fine-tuned, and updated regularly.

There will also be moments when the system flags something that isn’t really a defect. Those false positives need a human decision. Someone has to check the product, confirm what’s going on, and keep the process moving.

This means workers aren’t being replaced; they’re taking on more technical responsibilities.

Troubleshooting, regular maintenance, and knowing when to step in all become part of the job. Because of this, many manufacturers are investing heavily in upskilling their workforce. It’s becoming a key part of how the industry prepares for the future.

Vision systems also help manufacturers improve their environmental impact. When a defect is caught early, you don’t waste time and materials producing items that will only be thrown away. Catching problems sooner means less scrap and fewer reworks.

This directly reduces the amount of raw material a company uses, which supports long-term sustainability goals. It also cuts down on energy consumption. When production lines run smoothly without sudden stoppages or repeated fixes, they use less power overall.

All these improvements support greener operations. And in today’s market, that matters. Customers, investors, and regulators are increasingly focused on sustainability. Companies that reduce waste and use resources more responsibly get a real competitive advantage.

When you look at why companies invest in Computer Vision in production, the reasons are usually practical. Here are a few long-term gains:

It’s about making everyday work smoother. These aspects help in maintaining the stability and competition of factories.

The next step is deeper integration. Instead of individual inspection stations, factories will build entire processes with vision woven in from start to finish. Here’s what we expect to see more of:

And as these systems get easier to set up, even smaller factories will start adopting them.

“Factories want to make good products consistently, without surprises. Vision systems help them do that by giving them better visibility and faster feedback.” That’s really the core idea. With tools like Control Automated Inspection, Machine vision systems, and real-time Production line monitoring, manufacturers can catch problems early, reduce waste, and keep lines running smoothly. And as more companies adopt these technologies, the ones that don’t may find it hard to keep up.