How Computer Vision AI is Impacting the Steel Manufacturing Industry in 2025

Ruchir Kakkad

CEO & Co-founder

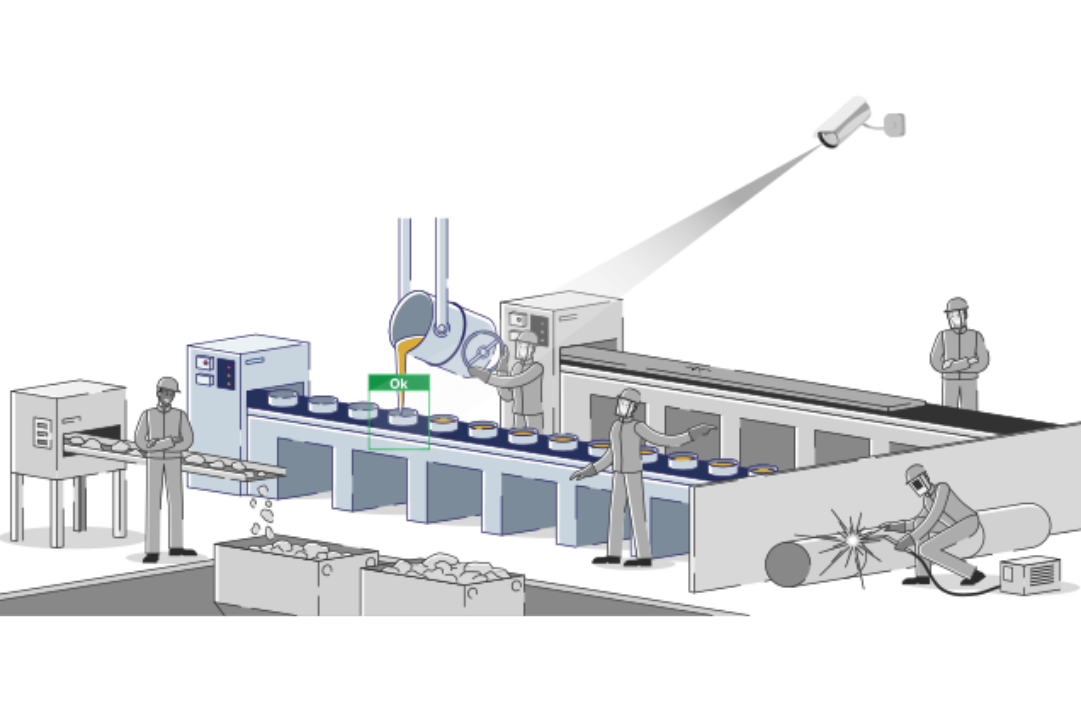

Artificial intelligence (AI), especially computer vision-based AI, has become a cornerstone of modern industrial innovation. Computer vision AI refers to algorithms, cameras, and computing hardware that allow machines to interpret visual information and make intelligent decisions. In manufacturing, these industrial AI applications augment or replace manual observation and inspection, enabling faster and more consistent analysis of products and processes. From assembly lines to warehouses, AI applications are delivering new efficiencies by automating visual tasks like quality inspection, inventory tracking, and safety monitoring. This trend is a key part of Artificial Intelligence in Industry 4.0, the broader digital transformation toward data-driven, connected, and autonomous operations.

While many sectors have enthusiastically embraced AI and automation, AI in steel manufacturing is only recently gaining momentum. Heavy industries like steel production have traditionally relied on manual processes and century-old legacy equipment. However, the potential gains from computer vision AI in steel are massive. AI can monitor high-temperature processes that humans cannot safely observe, detect product defects invisible to the naked eye, and optimize complex production parameters in real time.

As a cornerstone of global infrastructure, the steel industry faces intense pressure to modernize. The sector is grappling with fluctuating demand, rising production costs, and the need for more sustainable practices. These challenges make steel an ideal candidate for digital disruption. Steel Industry Digital Transformation is now a strategic priority for many producers seeking to stay competitive. By integrating AI technologies, companies are not only addressing chronic issues but also unlocking new efficiencies and capabilities.

Yet until recently, steel manufacturing has been slower to adopt advanced automation than other industries. Many mills have been operating for decades with deeply entrenched processes and cultures. Forward-looking steelmakers now recognize that embracing AI and automation is critical to remain efficient and profitable. The industry is “ripe for transformation” because the gap between current practices and what’s technologically possible is so wide. Automation in steel manufacturing is poised to accelerate rapidly in 2025 and beyond, driven by clear ROI demonstrated in pilot projects.

Steel production is extremely energy-intensive, with the industry responsible for roughly 7% of global carbon emissions. Running blast furnaces, smelters, and rolling mills around the clock consumes vast amounts of electricity and fuel. High energy usage drives up production costs and raises sustainability concerns amid stricter environmental regulations. Many steel plants operate at suboptimal energy efficiency, using fixed recipes that don’t adapt to real-time conditions. Reducing energy use without sacrificing output is a core challenge where AI-driven analysis can make a significant difference.

Steel mills rely on massive industrial equipment operating under harsh conditions. High temperatures, mechanical stress, and continuous operation take a toll on machinery. Unplanned equipment failures are especially costly, as a single breakdown can halt 24/7 production lines. Traditionally, mills have depended on periodic inspections and scheduled maintenance, but unexpected failures can still occur with catastrophic consequences.

Consistently producing high-quality steel is non-negotiable, as the material often ends up in critical structures, automobiles, and appliances. Yet maintaining strict quality control can be difficult in a fast-paced mill environment. Minute defects such as micro-cracks, surface blemishes, or dimensional deviations can arise at various stages of production. Human inspectors stationed at checkpoints have limitations – small flaws can escape detection, and checking every inch of steel is impractical. Quality escapes lead to rework and scrap, wasting energy and materials while undermining efficiency.

Steel producers operate within complex, global supply chains, managing raw materials, in-process inventory, and finished steel delivery. Demand can be highly volatile, influenced by economic cycles and downstream sectors. Traditional planning tools often struggle with this variability, resulting in overproduction (excess inventory) or underproduction (missed sales). Coordinating production schedules with demand forecasts and optimizing inventory levels is challenging with legacy systems, often leading to mismatches between production and market needs.

One of the most promising AI applications for steelmakers is predictive maintenance, which uses AI-driven analytics to predict when equipment is likely to fail. AI systems ingest data from sensors (vibration, temperature, pressure) and visual feeds to assess machine health. By recognizing patterns that precede failures, AI can alert engineers days or weeks in advance, allowing maintenance to be scheduled optimally and avoiding catastrophic breakdowns.

For example, machine learning can continuously monitor critical assets like blast furnace refractory linings or continuous caster rollers. Thermal imaging cameras monitor steel ladles for hotspots indicating thinning refractory or impending leaks. Early warning enables crews to take ladles out of service for repair before spills occur, improving safety and avoiding costly interruptions. Tata Steel implemented AI monitoring on rolling mills and reduced unplanned downtime by 15%, translating to significant cost savings and higher output.

Quality control is being revolutionized by computer vision AI. Instead of relying solely on human inspectors, steel manufacturers are installing high-resolution cameras and machine vision systems at critical production points to automatically inspect products for defects. These AI-driven systems analyze images of steel surfaces to catch imperfections such as cracks, scratches, dents, or coating issues. They operate at high speed with consistent accuracy, scanning every piece rather than just samples.

Austrian steelmaker Voestalpine uses AI vision systems and reportedly reduced defect rates in final products by over 20%. Another example involves optical character recognition (OCR) for verifying identification markings stamped on steel plates, achieving 100% accuracy in reading codes compared to manual checks. Computer vision enables automation in quality assurance by finding tiny defects, ensuring product traceability, and greatly speeding up inspection processes.

AI is being harnessed for process optimization – automatically controlling and refining the steelmaking process itself. Steel production involves numerous stages with complex parameters that need precise control. AI systems can analyze real-time data from modern steel plants to find optimal settings that humans might not easily discern. Machine learning models correlate furnace sensor readings with steel quality outcomes and autonomously adjust parameters like airflow or fuel rates.

ArcelorMittal uses AI to monitor blast furnaces and adjust parameters such as temperature and raw material mix on the fly, resulting in more consistent steel quality and notable energy consumption reduction. Process automation driven by AI also helps reduce human error and variability, creating Smart steel factories where systems self-correct to keep outputs within specifications.

AI application to improve energy efficiency is high-impact for steel producers seeking cost reduction and sustainability gains. Machine learning models analyze production data to pinpoint where energy is being used inefficiently and recommend optimal temperature profiles or timings. Swedish steelmaker SSAB employs AI to optimize electric arc furnaces, adjusting energy input in real time based on melting progress, resulting in 7% energy consumption reduction and significantly lower carbon emissions.

Smart energy management within plants uses IoT sensors and AI to coordinate energy use, scheduling energy-intensive tasks for times when electricity is cheaper or renewable energy supply is high. Computer vision assists sustainability by monitoring environmental parameters, detecting smoke opacity or slag foam levels to help control emissions in real time.

AI applications extend beyond the factory floor to planning and supply chain management. Traditional forecasting methods often yield imprecise results in volatile steel markets. AI analyzes large, diverse datasets – historical sales, economic indicators, customer patterns, market sentiment – to predict future demand more accurately. AI-powered demand forecasting continuously adjusts predictions as new data comes in, allowing steel producers to better match production to market needs.

Nippon Steel implemented an AI-based system analyzing market trends and past order data to forecast demand, optimizing inventory and logistics while reducing excess stock and delivery times. AI also streamlines supply chain operations through route optimization, computer vision for inventory tracking, and automated ordering systems based on predicted needs.

Leading steel manufacturers worldwide have implemented AI and computer vision projects with impressive results:

Tata Steel implemented AI-driven predictive maintenance on rolling mills, analyzing sensor data to identify potential failures before they occurred, leading to 15% reduction in unplanned downtime and substantial maintenance cost savings.

ArcelorMittal uses AI for process optimization in smelting operations, with real-time analysis of blast furnace data. AI autonomously adjusts temperature and chemical mix parameters, reducing energy consumption by about 5% while improving production output.

Voestalpine deployed AI-driven computer vision for quality control, with high-resolution cameras inspecting steel surfaces for micro-cracks and anomalies. This reduced defect rates in final products by over 20%.

POSCO integrated AI into workplace safety and maintenance, using cameras and computer vision to monitor for safety hazards and equipment malfunctions, reducing workplace accidents by approximately 12%.

SSAB leverages AI to improve sustainability, with machine learning analyzing electric arc furnace operations and dynamically adjusting energy input, resulting in 7% energy usage reduction and significantly lower CO emissions.

These cases demonstrate measurable improvements: cost reductions through reduced downtime and energy savings, improved quality with lower defect rates, and enhanced safety with fewer workplace incidents.

AI-driven optimizations directly translate into cost reductions. Predictive maintenance prevents expensive equipment failures, while process control reduces raw material and energy costs. BCG found that steel companies can reduce raw material costs by more than 5% through smarter process control and yield improvement. Inventory optimization via AI forecasting can cut carrying costs, with some pilots reporting 15% reduction in inventory costs.

Automated vision inspection systems act as tireless quality control inspectors, catching defects humans might overlook. This ensures substandard products are detected before shipping, increasing customer satisfaction and trust. AI doesn’t just catch defects; it helps prevent them by enabling better process control. Real-time feedback loops mean processes yield higher quality output continuously, with consistent standards applied to every piece.

Through predictive maintenance, AI significantly cuts unplanned equipment downtime by forewarning issues. Smart scheduling algorithms minimize needless line stoppages by sequencing production orders to reduce machine setting changes. AI-based quality control prevents scenarios where quality problems force line shutdowns by keeping quality in check continuously.

Computer vision actively monitors for unsafe situations, detecting workers entering restricted zones or not wearing proper safety gear, with instant alerts issued. Robotics and automation remove humans from dangerous tasks, while predictive maintenance reduces catastrophic equipment failures that could injure staff. Steel companies embracing AI safety programs have seen concrete results in fewer injuries and stronger safety cultures.

Many steel companies face data integration as the primary hurdle. Older mills often have legacy equipment never designed to collect or share data digitally. Much process information resides in isolated control systems or paper logs. Without comprehensive, clean datasets covering whole production lines, training effective AI models is difficult. Companies must invest in modernizing equipment with IoT sensors and adopting data standards before AI can be deployed effectively.

Deploying AI involves significant capital and operational expenditures, including new hardware like cameras and industrial computers, software licenses, network infrastructure upgrades, and specialist hiring. These costs can be barriers, especially for smaller companies. However, phased implementation starting with smaller-scale projects that demonstrate value can help justify broader rollouts.

Steel companies need to bridge skills gaps between traditional mechanical expertise and modern AI/data science capabilities. Major investments in training programs are required to equip existing staff with working knowledge of AI tools. Companies like POSCO have launched internal “Smart Factory” training academies to instill digital skills and change organizational mindsets toward data-driven approaches.

The future envisions fully smart, autonomous factories where every production stage is instrumented with sensors and vision systems, with AI algorithms coordinating entire operations. Linked production assets and AI software could autonomously adjust process variables to maintain optimal output with minimal human intervention. Future AI-enabled steel manufacturing could integrate with supplier and customer systems, creating seamless demand-triggered production adjustments.

A new generation of collaborative robots designed to work safely alongside humans will play bigger roles in steel production. Cobots excel at tasks like machine tending, material handling, inspection, and packing. They bring precision and endurance while humans provide judgment and flexibility. Early adopters in metals have reported significant productivity gains, with some seeing 60% efficiency increases and ROI under two years.

Digital twins – virtual replicas of physical assets fed by real-time data – enable truly smart, data-driven factories. Examples include Purdue University’s Integrated Virtual Blast Furnace, which mirrors physical furnaces in real time, allowing engineers to understand internal states and test scenarios virtually before applying them. Digital twins provide live dashboards of operations and testbeds for AI-driven optimization in risk-free environments.

The steel industry, often seen as a symbol of heavy industrys past, is rapidly embracing an AI-driven future. As weve explored, computer vision AI is impacting steel manufacturing in 2025 in profound ways: boosting efficiency through predictive maintenance and process automation, ensuring top-notch quality with automated visual inspection, optimizing energy use for sustainability, and streamlining supply chains with intelligent forecasting. Early adopters have demonstrated substantial gains, from lower costs and higher quality to safer workplaces proving that AI is not just a buzzword but a practical tool for Steel Industry Digital Transformation.

Technologies once confined to research labs are now deployed on the mill floor, with companies like WebOccult providing tailored computer vision solutions to tackle steelmakers toughest challenges.