AI Vision in Steel & Heavy Machinery: Improving Safety and Efficiency

Ruchir Kakkad

CEO & Co-founder

Steel is required in construction, transport, and numerous other fields, whereas heavy machineries are required in fields like construction, mining, and many more activities; These two industries play a very crucial part for others as well, but both sectors come with their own challenges and concerns regarding safety, inefficiency, and high costs. Where AI vision can really benefit both these industries. They use cameras and sensors to monitor a process in real-time, keeping it much safer, more efficient, and even reducing costs. Together, they are transforming what we call Industrial Safety AI, making workplaces smarter and more secure.

AI Vision in the Steel Industry

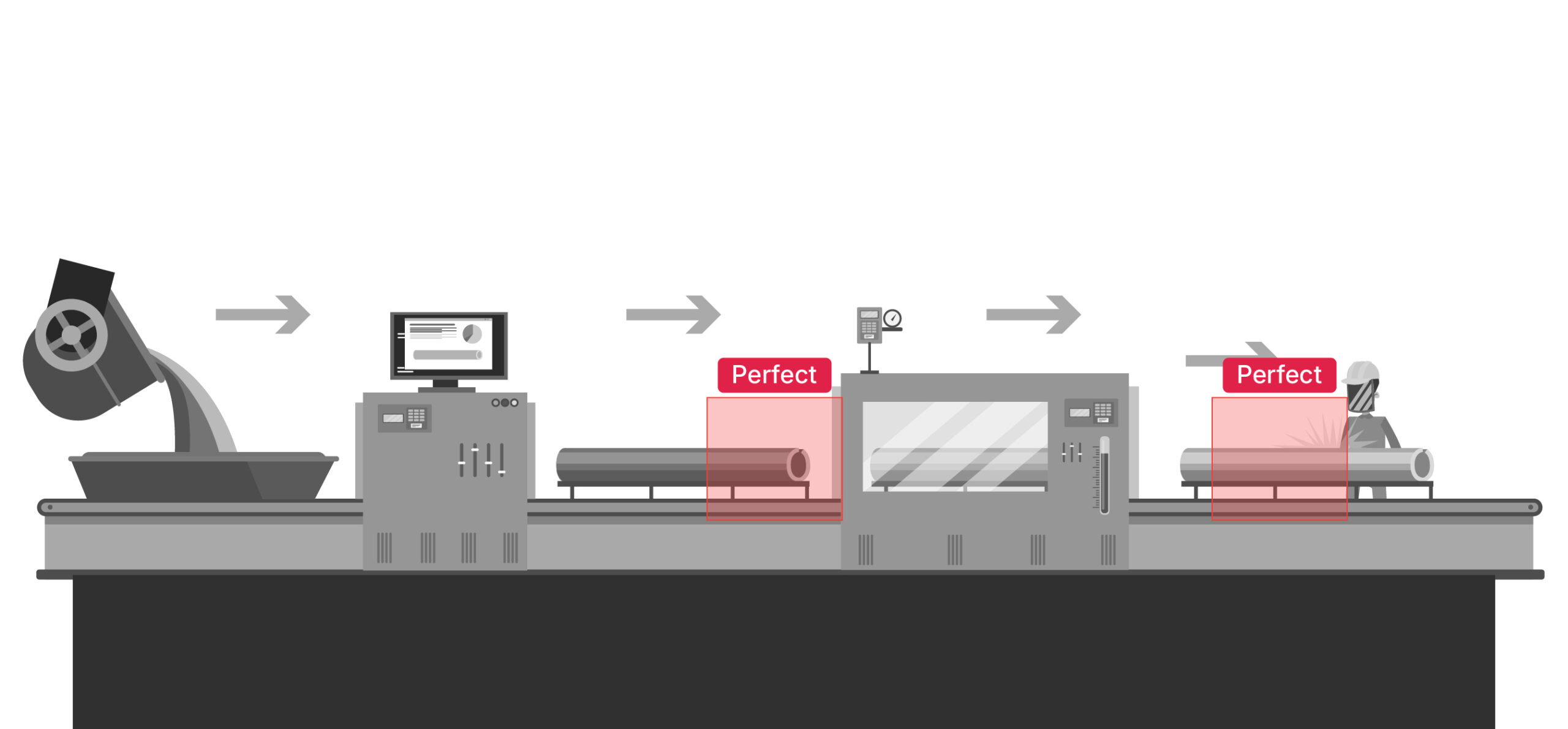

This has many complex steps in making steel, and it might go wrong at any time, increasing costs and delaying the whole thing. AI Vision has lately been a huge help in tracking these processes on a consistent basis. Here’s how it works:

AI Vision in the Steel Industry keeps a tab on everything as materials move along a production line. The moment something goes awry, it catches the issue at its inception before it develops into a big problem.

Maintenance schedules are based on time, though that might not be in parallel with the actual cases when machines need repair. AI Vision can help track small signs of wear or other issues, such as rising temperatures can be detected early with the help of the predictive maintenance suggested through AI; this can help in taking steps and repairing before anything breaks down, which will help in saving time and reducing downtime.

Steel needs to be maintained at high standards. When it comes to the steel industry, AI vision captures abnormalities and defects that are usually ignored by the human eye and makes sure that the quality stays intact, which will help in reducing wastage and gaining customers’ trust and satisfaction.

Steel production uses a great quantity of energy, while any kind of wasting of the same results in fast-growing costs. AI Vision in the Steel Industry tracks all energy consumption throughout the plant and enables the owners to identify where energy is being wasted. This leads to more environmentally friendly practices and efficiency improvement in steel plants.

AI Vision plays an important role in improving safety on a constant basis by monitoring the environment; as there is the presence of molten metal, heavy machinery, and immense heat levels which raises the concerns regarding safety as steel plants are hazardous places to work, so AI vision helps in few aspects to make sure of safety concerns.Here’s how:

Hazard Detection

AI Vision in the Steel Industry tracks the movement of workers and equipment. In the case of a restricted area entrance or problem machinery, an alert is sent to supervisors via the system. This form of workplace safety monitoring helps prevent accidents from occurring in the first place.

Immediate Alerts

Industrial safety AI actively monitors and alerts operators in case of an accident, may it is about overheating of any equipment or if anyone is in a hazardous area; which helps workers to take immediate action at the workplace, and this helps in keeping everyone safe.

There are machineries that are really important, like cranes, bulldozers, and excavators are in action every day on building and mining sites; but these are quite dangerous at the same time if not operated carefully. AI for Heavy Machinery can help improve both safety and efficiency within machinery operations. How?

AI Vision constantly monitors the work area around the placement of heavy machinery, which can detect hazards such as obstacles or workers getting too close. And this sort of detection helps the operating personnel to take the best steps to avoid any sort of accidents with immediate effect. This kind of workplace safety monitoring has been a huge leap forward in accident prevention.

AI for Heavy Machinery also watches how the machines are performing. This gives the operator an advanced idea to fix the problem before it causes an issue, as it might save time and repair expenses, as AI vision might monitor if the machine is taking more fuel than it should be, or if any part is malfunctioning, then the system will send a warning in advance.

One of the most common reasons for machinery breakdown is overloading; AI for heavy machinery monitors the load carried to stay within safe limits by these machines. This constant monitoring helps in preventing accidents and also ensures life safety. This form of machine vision for heavy machinery allows a safe, smooth, and efficient work environment.

Safety is a major concern with operations in steel plants and heavy machinery. Industrial Safety AI helps to identify threats the moment they appear with the help of Real-time hazard detection, which reduces the likelihood of accidents. Here’s how it works:

AI Vision in the Steel Industry monitors the movement of molten metals and worker positions. So it sends an immediate alert when a spill or accident happens, or when any worker goes closer to a dangerous place, which helps in preventing accidents before they occur through real-time hazard detection.

AI for Heavy Machinery continues to monitor its surroundings. When an obstacle or a person is too close to the machine, the system sends a warning to the operator, with enough time to stop the machine and avoid an accident. This blend of machine vision for heavy equipment and workplace safety monitoring has drastically reduced risks across many industries.

Efficiency will always play an important role in manufacturing, especially in the production of steel. Steel is quite costly to produce, and even small, ineffective procedures can add to greater costs. AI Vision in the Steel Industry increases efficiency, lowering costs by tracking everything in real time.

AI Vision in the Steel Industry monitors all stages involved in the production of steel. Whatever is delayed or goes awry, the system detects that in no time. This prevents bottlenecks from happening and contributes to efficiency improvement in steel plants.

AI Vision in the Steel Industry provides quality control by improving the quality of goods in production, locating mistakes early in order to avoid extensive problems. Either lower-grade products are removed, reducing waste, or higher-quality products are produced consistently.

A lot of energy is required to produce steel. AI Vision in the Steel Industry identifies where energy is going to waste and identifies ways to reduce consumption. Energy savings assist plants in cutting costs and becoming more environmentally friendly.

One of the most significant advantages of this technology is predictive maintenance with AI. It does not wait for the machines to break down. Instead, it predicts when they will fail based on real-time data. This gives maintenance teams enough time to fix problems before they happen, reducing downtime and costs.

AI Vision in the Steel Industry monitors critical equipment, including furnaces, engines, and more. It sends a warning if it detects early signs of trouble, such as temperature changes or unusual vibrations, so maintenance teams can act before a failure occurs.

AI for Heavy Machinery monitors the health of engines and hydraulic systems. It can detect if a part is wearing down and trigger an alert system. This enables operators to prevent breakdowns and reduces any time wasted while waiting for repairs.

AI Vision in the Steel Industry and AI for Heavy Machinery work hand in hand with automation systems to make industrial operations more efficient. Certain tasks, when automated, reduce the need for manual work and speed up the overall process.

In factories, many visual inspections that were once done by hand can now be automated. The machine vision for heavy equipment checks each product for defects, which increases speed and reduces human error.

Heavy machinery load checks and performance monitoring are automated by AI for Heavy Machinery. This reduces the chances of human error and helps to keep machines operating at their best.

Looking at how far the industry has come, it’s clear that AI Vision in the Steel Industry and AI for Heavy Machinery are changing the way people work. These tools are not just about adding technology to the job; they’re about creating safer and smarter workplaces. With Industrial Safety AI, teams can now spot problems early, avoid costly delays, and keep both workers and machines in better shape. It takes a lot of the guesswork out of daily operations, which helps everyone focus more on doing the job right.

When we combine things like predictive maintenance with AI, machine vision for heavy equipment, and real-time hazard detection, companies can prevent issues instead of reacting to them. This approach saves time, money, and even lives in some cases. The efficiency improvement in steel plants also means less waste, lower energy use, and smoother production overall.

At the end of the day, it’s not just about machines getting smarter. It’s about people working in safer environments and businesses running with more confidence. The connection between technology and human effort is what truly drives progress in these industries.