Worker Safety Monitoring

Prioritize safety with real-time alerts on safety practices.

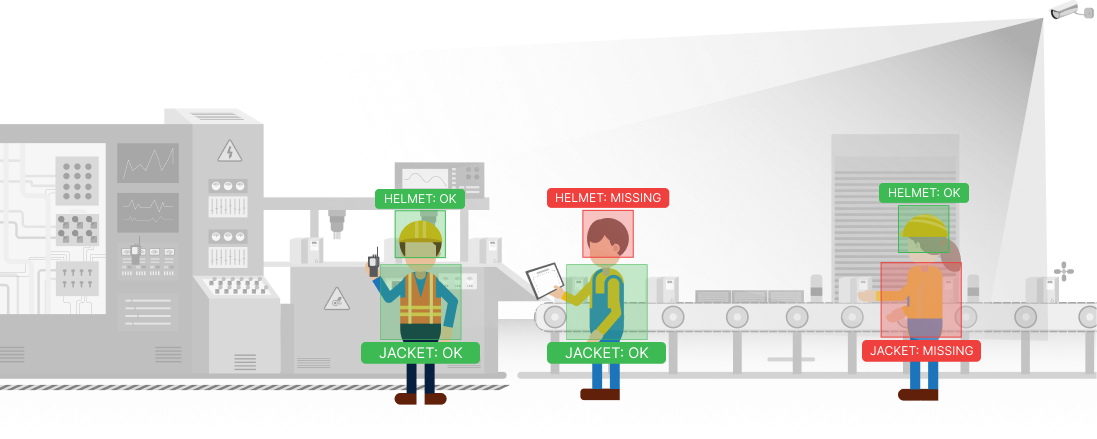

Our workforce monitoring solution uses AI-powered safety through computer vision to monitor compliance with safety protocols like wearing PPE kits. It helps workers avoid danger zones. It can be integrated with the existing CCTV setup to provide real-time insights. This helps in maintaining a safe industrial environment using automated safety monitoring techniques.

The workforce often fails to wear mandatory safety gear. This increases the risk of workplace injuries. This is where Workplace Safety Monitoring becomes important.

The workforce often fails to wear mandatory safety gear. This increases the risk of workplace injuries. This is where Workplace Safety Monitoring becomes important.

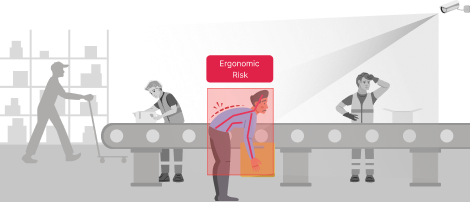

Unintentional entry into hazardous areas makes workers prone to accidents or injuries. A strong safety compliance mechanism is required. It is to prevent such occurrences.

Monitor restricted zones in real time and receive alerts when workers enter high-risk areas using workplace safety automation tools.

Difficult to enforce safety protocols by manually monitoring the workforce or risky zones. Workforce Compliance Monitoring helps automate and enforce these policies across facilities.

AI based monitoring promises consistent enforcement of safety protocols. That is without manual intervention.

Lack of real-time visibility and no data makes it impossible to identify and fix recurring safety issues.

Get detailed insights into what is happening and safety compliance trends to fix recurring issues proactively.

Safety of the workforce is important for industries. Thus, the use case is beneficial to many stakeholders:

We evaluate your existing camera infrastructure. It is to integrate the solution seamlessly.

AI model is trained to detect safety violations like missing PPE or unauthorized zone entry.

We enable continuous monitoring of the workforce. Along with instant alerts for safety breaches.

Our system provides safety analytics. Those are to refine protocols and address compliance challenges.

Stay updated with the trending and most impactful tech insights. Check out the expert analyses, real-world applications, and forward-thinking ideas that shape the future of AI Computer Vision and innovation.

7:45AM at a busy automotive parts manufacturer. A delivery truck arrived at the dock. Usually, supervisors would take 10 minutes to scan paperwork. They’d also be keying in data. Instead, a camera quietly recorded the container ID, logged upon its arrival. And it tagged the shipment to a specific production line. All without a single […]

CEO & Co-founder

It’s 2:14 PM at a busy CFS gate. A trailer rolls in. The container is old, dusty and sun faded. The number is readable, but only if you look closely. The driver wants to move fast. The queue behind him is growing. The gate operator does what they have always done. Reads the container number. […]

CEO & Co-founder

Modern logistics depend on speed. Accuracy and visibility keep logistics moving. Across container yards and CFS hubs… teams still face blind spots. They rely on manual checks and delayed data. This leads to missed damages and inefficient movement of assets. Logistics teams can see clearly by combining cameras with computer vision. They can understand and […]

CEO & Co-founder