The Hidden Value of Visual Recordkeeping in Logistics and Manufacturing

Ruchir Kakkad

CEO & Co-founder

7:45AM at a busy automotive parts manufacturer.

A delivery truck arrived at the dock. Usually, supervisors would take 10 minutes to scan paperwork. They’d also be keying in data. Instead, a camera quietly recorded the container ID, logged upon its arrival. And it tagged the shipment to a specific production line. All without a single human keystroke

No queues. No guessing. No late logs. Just clear and visual evidence of what happened.

This moment highlights something most companies overlook. Visual recordkeeping in logistics and manufacturing is not just a “nice to have.” It is quickly becoming an important part of reliable operations.

For decades, industries have relied on manual logs for a long time. They have also depended on paper trails and spreadsheets. In logistics, a worker might check off every container movement by hand. In manufacturing, quality auditors might walk the line and record defects in clipboards.

But a truth no one likes to admit is:

Manual systems are built on memory and assumptions. They are reactive. And in fast‑paced environments, that gap between what happens and what’s recorded grows quickly. And it becomes a serious risk.

This is where AI vision recordkeeping systems change things.

Visual recordkeeping uses cameras and computer vision for logistics visibility and manufacturing oversight. Instead of relying on someone to write or type information… a system sees and records what happens directly. It records with timestamps, images and context. That data stays in the digital record forever.

This means:

And best of all is that it works in real time.

200,000 sq. ft. Warehouse. Think of that warehouse storing electronics components for a major manufacturer. In the old system, warehouse staff walked aisles to record stock levels. They updated the system at the end of each shift. By then, dozens of transactions were unrecorded. This led to errors.

With an AI vision recordkeeping system, cameras mounted at entry points and key aisles automatically track:

Nothing is manual. The system updates real‑time inventory tracking with AI. This gives managers clarity every second of the day.

There will be no more “we thought we had 50 units which turns out we had 30.” No more guessing. Only data you can trust.

In logistics, disputes are common. A container arrives. Damage is noticed later. Everyone blames someone else. Without proof, arguments increase and costs rise.

That is why visual audit trail logistics is not a record. It is accountability.

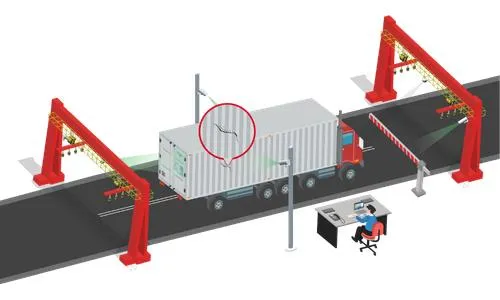

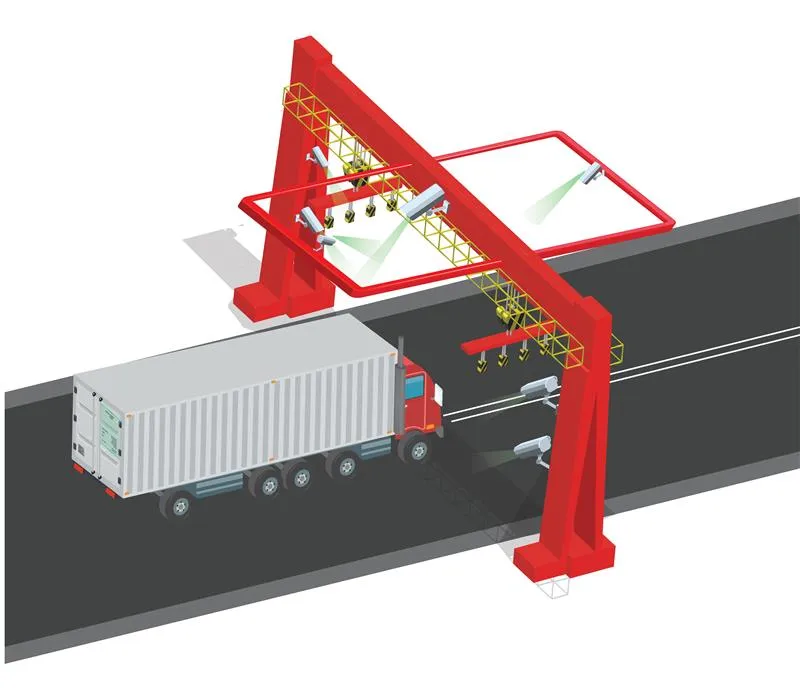

Instead of a worker saying, “I think the seal was fine.” Systems using AI container OCR recordkeeping capture:

This is not surveillance. It is visibility built on evidence. And it prevents hours wasted in debates or calls or reworks.

Now shift from logistics to the factory floor. In manufacturing, mistakes are expensive. One misaligned part can trigger a recall. One missed defect can cost a reputation. WebOccult’s smart manufacturing solutions bring precision, speed and real-time insights to your floor. Learn more about our manufacturing solutions here.

Here’s how visual recordkeeping helps:

Human inspectors are invaluable. But even the best can miss minute defects. WebOccult’s AI systems use computer vision for manufacturing quality control. They are to inspect parts at machine speed. They catch flaws that escape the human eye.

On an electronics board assembly line, as many as 500 units move through each hour. Traditional inspection methods catch roughly 85% of defects. Defect detection improves with AI vision. That means less rework and fewer warranty claims.

This is how factories meet rising customer expectations without increasing staff.

If a machine goes idle for 15 minutes. Or if a segment of the line slows down. The system detects it immediately. Cameras and sensors feed visual data into analytics. So, operations managers know exactly where delays happen.

Real‑world impact? A consumer appliances manufacturer reduced line downtime by 40% in 90 days. They achieved this after implementing vision‑based monitoring. The change meant they no longer waited for shift reports. Problems were visible at the moment they happened.

Safety incidents are not only tragic. They are costly. Vision systems can monitor hazards. They detect unsafe behavior and restricted areas. And they alert teams instantly. One site saw notifications for spill hazards and unauthorized machine access. Response times were cut almost in half.

Here, visual recordkeeping in manufacturing becomes a proactive partner in safety.

In many operations, logistics and manufacturing are separate silos. But both traditions struggle with the same core issues:

When systems record visual evidence instead of typed entries, the whole ecosystem becomes more reliable.

Consider a plant receiving components from multiple vendors. With visual recordkeeping:

From the yard to the factory line, the story of every part is clear.

![]()

In logistics hubs, manual logs track every container event. Gate‑in, gate‑out and movement entries can lag or go wrong. That means records may be late or incorrect. Instead, visual systems read container IDs and log them automatically.

This brings clarity to:

And because this visual record is tied to real timestamps and images, disputes over lost or damaged goods are easier to resolve. Operations become predictable instead of reactive.

You may be thinking that all this sounds valuable. But does it justify investment?

Here’s a reality check:

In aggregate, these benefits do not just save money. They create competitive advantages.

If followed you will be saying that “We stopped guessing what happened last Tuesday. For the first time, we knew.”

That’s the whole point of visual recordkeeping.

Industries everywhere are pushing for faster delivery. They also demand higher quality and better traceability. Customers expect zero defects. Logistics partners demand transparency. Regulators want compliance proof.

Traditional approaches cannot keep this up.

With tools like computer vision for logistics visibility and AI‑powered manufacturing monitoring, teams no longer chase problems. They prevent them.

And because these systems are learning and improving every day, the value you capture compounds over time.

In logistics and manufacturing, the difference between chaos and confidence is clarity. Visual recordkeeping gives you that clarity. Every container, every component, every step of your process is recorded. It is even verified and actionable. The goal is to stay in control, prevent mistakes before they happen and make smarter choices instantly.

Ready to transform your operations? WebOccult’s vision systems bring clarity you can trust. They make your operations more efficient. And keep every floor and yard free of surprises. See it in action. Start making every move count.