Lead Frame And Substrate Inspection

Inspect Before You Bond. Prevent Failure Before Assembly.

Lead frames and substrates form the physical base for semiconductor packages, any warpage, contamination, or dimensional fault at this level can cause bonding issues, electrical shorts, or total package failure. Manual inspection is inconsistent, and traditional 2D tools often miss warpage or multilayer misalignment. AI-powered Lead Frame and Substrate Inspection uses advanced 2D/3D computer vision to detect surface defects, warpage, and structural misalignment before die attach or wire bonding. With micron-level resolution and intelligent classification, the system ensures only flawless frames proceed to the next stage.

Scratches, dents, or oxidation on the lead frame surface may go undetected in visual checks, leading to bonding failure.

Substrate thickness, paddle depth, or pad spacing variations cause die misplacement or electrical mismatch.

Mechanical warpage due to improper storage or handling can cause poor die attach, especially in multi-layer substrates.

Human error and subjective judgment reduce reliability and throughput under high-volume demands.

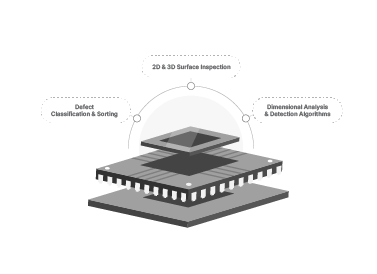

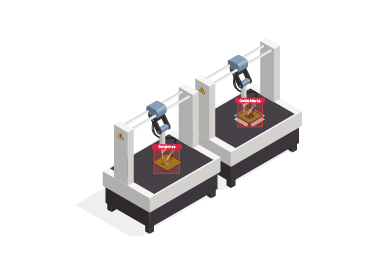

Captures surface irregularities, corrosion, scratches, and dents using high-resolution visual and depth scanning.

Measures pad pitch, bond fingers, paddle flatness, and outline dimensions against golden specs.

Uses machine vision with 3D reconstruction to detect bending or structural warpage in substrates and frames.

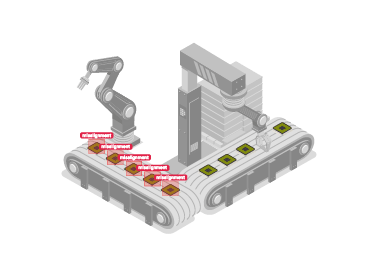

Automatically classifies defects and routes defective units to rework bins or rejects them, no operator input needed.

We begin by mapping the inspection point between cleaning and die attach stages, integrating the system with your substrate loader/unloader and frame handler.

Combining area-scan cameras and laser triangulation sensors, we enable full-surface and height-map acquisition for each lead frame or substrate in motion.

Our AI model is trained on real-world defect libraries from your past rejects, scratches, oxide marks, pad shifts, to achieve context-specific classification.

Inspection outcomes are sent to the MES (Manufacturing Execution System) in real time, triggering robotic sorters or binning logic to separate units by defect class or reworkability.

Stay updated with the trending and most impactful tech insights. Check out the expert analyses, real-world applications, and forward-thinking ideas that shape the future of AI Computer Vision and innovation.

Steel is required in construction, transport, and numerous other fields, whereas heavy machineries are required in fields like construction, mining, and many more activities; These two industries play a very crucial part for others as well, but both sectors come with their own challenges and concerns regarding safety, inefficiency, and high costs. Where AI vision […]

CEO & Co-founder

Some achievements do not arrive with loud announcements or dramatic celebrations. They arrive quietly, almost gently, carrying a kind of weight that only people close to the work fully understand. WebOccult’s Best Paper recognition at the IEEE was one such moment. Out of more than 450 research papers submitted from across the world, only five […]

CEO & Co-founder

People usually don’t think about logistics until there’s a delay in order delivery. On the other hand, there are millions of products that move across borders every single day, as their journey includes going through different ports, warehouses and distribution centres before the product reaches its respective owner. So there’s a lot that happens behind […]

CEO & Co-founder