PHOTOMASK DEFECT INSPECTION

Catch Sub-Micron Errors. Preserve Pattern Integrity. Enhance Yield at the First Step.

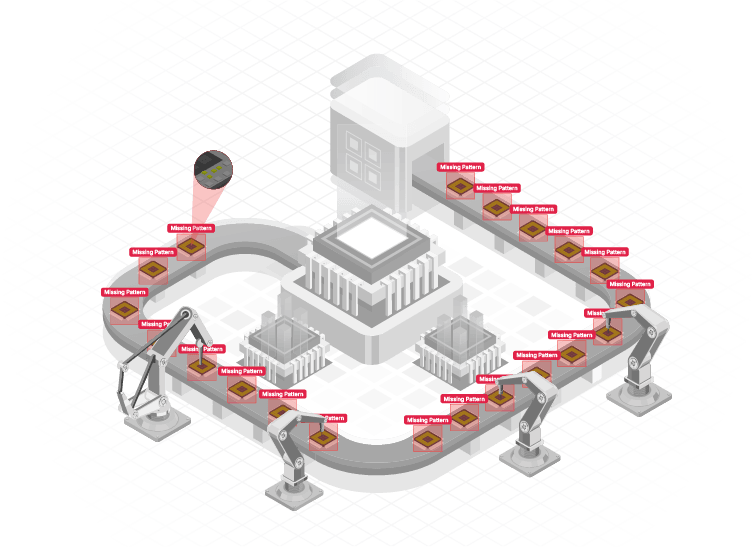

Photomasks are the blueprint of semiconductor manufacturing, and even the tiniest imperfection can lead to costly wafer defects across thousands of chips. Traditional manual and rule-based inspections are no longer viable for today’s advanced nodes. AI-powered Photomask Defect Inspection leverages ultra-high-resolution imaging combined with deep learning to detect sub-micron flaws like missing patterns, particles, scratches, or deformation, before they are replicated during lithography.

Human inspection or traditional rule-based systems struggle to catch nano-scale particles or structural flaws on masks.

High rejection rate of usable masks due to overly sensitive or static threshold systems.

Even when defects are detected, they are often not correctly categorized, slowing down root cause analysis.

Long inspection cycles and repeated mask validations delay exposure steps and increase cycle times.

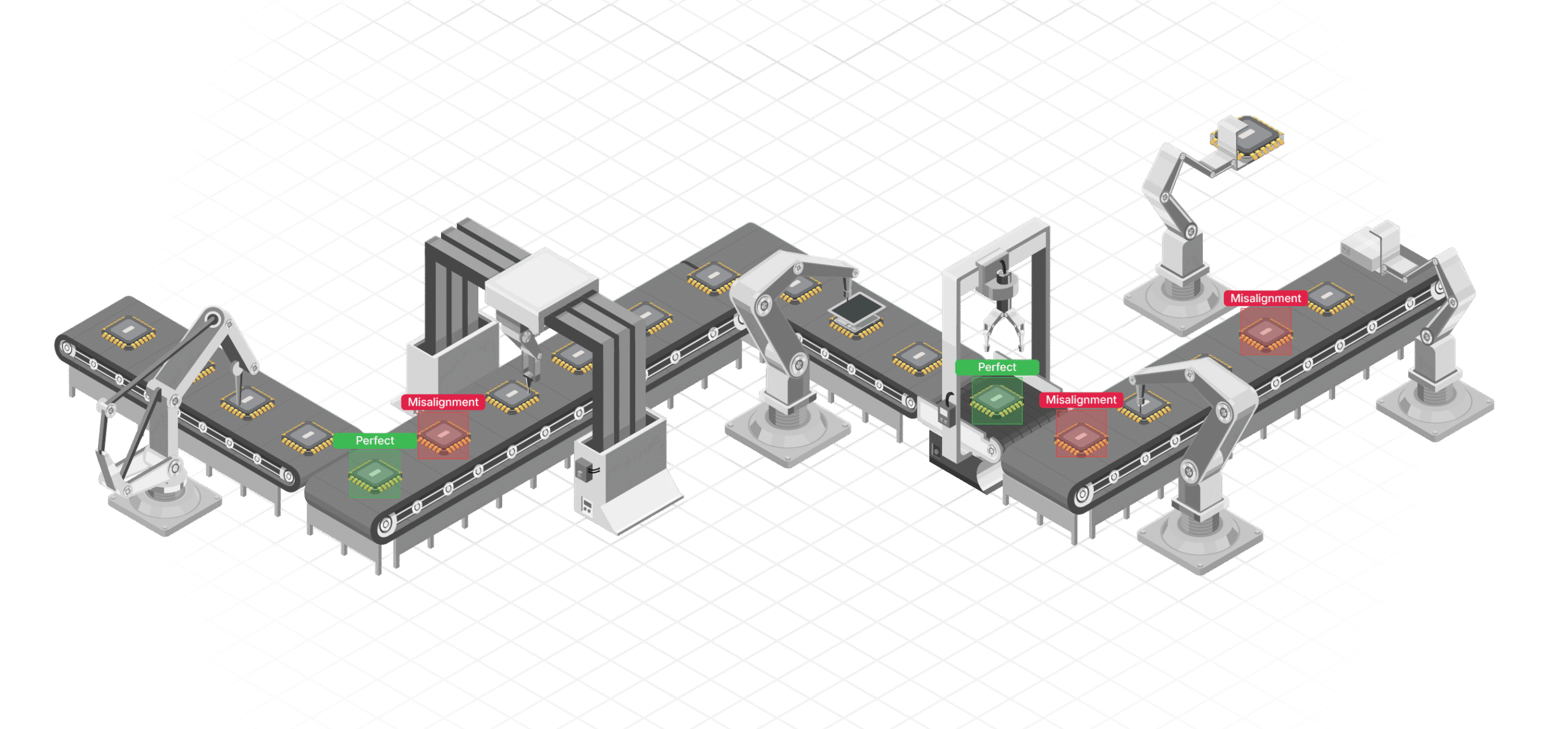

AI models trained on vast defect datasets to detect and differentiate critical vs. non-critical anomalies.

Micron and sub-micron precision imaging using specialized optics to catch the smallest pattern inconsistencies.

Classifies defect types (particles, scratches, edge defects, missing lines) and ranks them by severity and location.

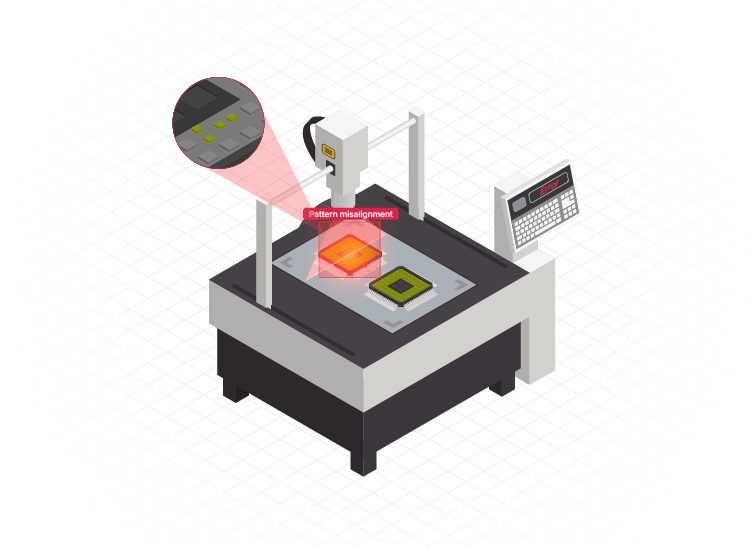

Compares actual mask pattern with design files (GDSII) for pixel-level mismatch detection.

The system begins by ingesting GDSII design files of the intended mask layout. These files are used to create pixel-level reference patterns for comparison.

Specialized imaging systems are calibrated to achieve ultra-high resolution (sub-100nm) and correct for lens distortion, lighting uniformity, and reflectivity of mask surfaces.

Historical mask defect data, including particle types, line breaks, and haze, is used to train a defect classification model that distinguishes real issues from noise or permissible variations.

Captured images are analyzed frame-by-frame using AI models, and inspection results are displayed on an intuitive dashboard. Critical defects are flagged for review, while acceptable ones are auto-classified, reducing manual load.

Stay updated with the trending and most impactful tech insights. Check out the expert analyses, real-world applications, and forward-thinking ideas that shape the future of AI Computer Vision and innovation.

Steel is required in construction, transport, and numerous other fields, whereas heavy machineries are required in fields like construction, mining, and many more activities; These two industries play a very crucial part for others as well, but both sectors come with their own challenges and concerns regarding safety, inefficiency, and high costs. Where AI vision […]

CEO & Co-founder

Some achievements do not arrive with loud announcements or dramatic celebrations. They arrive quietly, almost gently, carrying a kind of weight that only people close to the work fully understand. WebOccult’s Best Paper recognition at the IEEE was one such moment. Out of more than 450 research papers submitted from across the world, only five […]

CEO & Co-founder

People usually don’t think about logistics until there’s a delay in order delivery. On the other hand, there are millions of products that move across borders every single day, as their journey includes going through different ports, warehouses and distribution centres before the product reaches its respective owner. So there’s a lot that happens behind […]

CEO & Co-founder