SLAB DIMENSION & ALIGNMENT CHECK

Measure accurately. Align precisely. Eliminate waste before it rolls forward.

Slight misalignments or dimensional inaccuracies in steel slabs during early stages can snowball into major product defects downstream. Manual caliper checks or edge-based sensors are limited in both accuracy and coverage, leading to off-spec output, wastage, and line slowdowns. AI-powered Slab Dimension & Alignment Check uses real-time computer vision to measure slab width, thickness, edge straightness, and alignment during rolling. It continuously validates dimensions against set tolerances and flags deviations, ensuring the process stays precise from the start.

Inaccurate width, thickness, or shape leads to product rejection or trimming loss.

Crooked entry into rollers or downstream units causes uneven rolling or jams.

Spot checks dont capture continuous variation across slabs, especially under high speed.

Thermal expansion, inconsistent feed rate, or load fluctuations distort slab consistency.

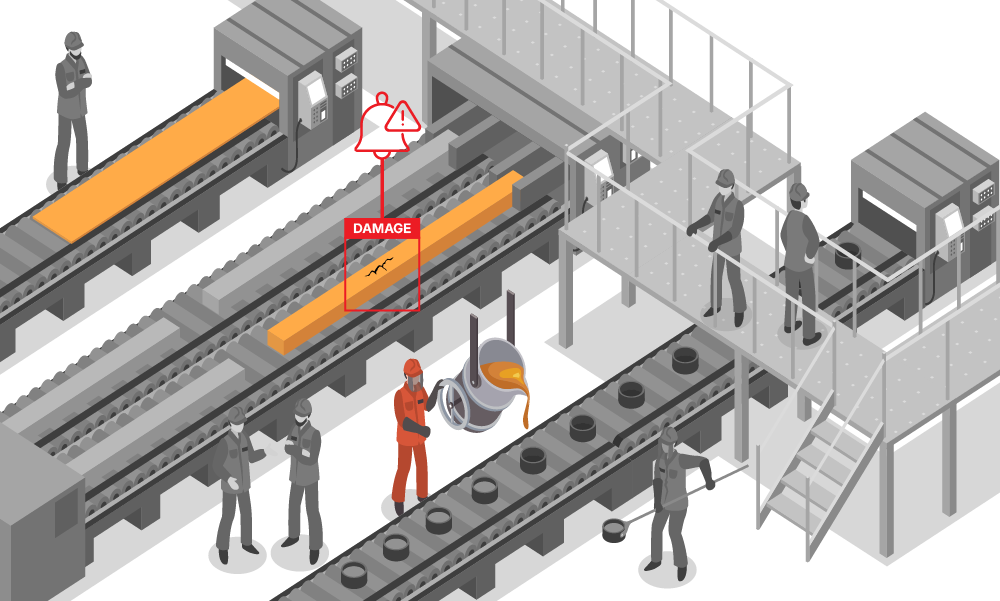

Captures continuous width, thickness, and tapering across slab length in millimeters.

Tracks deviation from centerline and detects lateral shifts during rolling.

Operators are notified when slabs fall outside configured dimensional thresholds.

Can auto-adjust cutters or side guides based on alignment feedback.

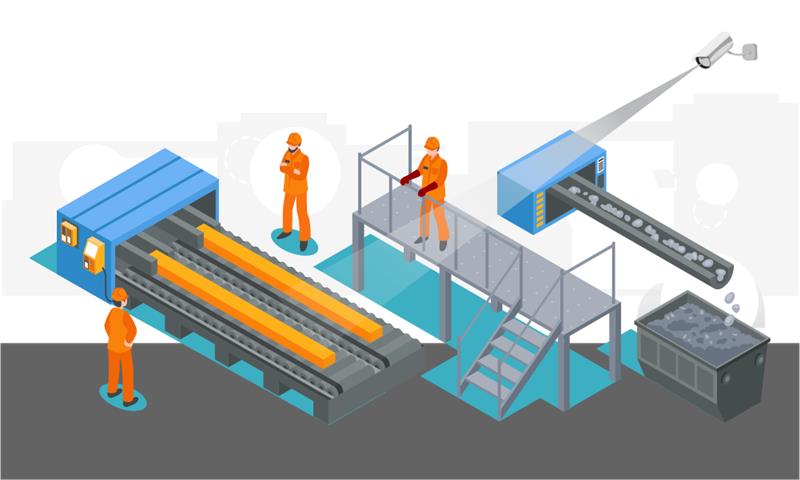

We work with your production and QA teams to identify the most dimension-sensitive sections, typically between caster exit, descaler zone, and initial roughing stands.

High-speed, high-res cameras are mounted at 3+ angles (top + both edges) to capture slab shape and line position. Each setup is calibrated for steel grades and light conditions.

We use past QC logs to train models that identify when and how slabs deviate, whether due to uneven cooling, feeder irregularity, or guide misalignment.

Deviation triggers are integrated with hydraulic rollers, guide controllers, or cutters, either for manual override or automatic micro-adjustments. Logs are archived for post-shift quality reviews.

Stay updated with the trending and most impactful tech insights. Check out the expert analyses, real-world applications, and forward-thinking ideas that shape the future of AI Computer Vision and innovation.

7:45AM at a busy automotive parts manufacturer. A delivery truck arrived at the dock. Usually, supervisors would take 10 minutes to scan paperwork. They’d also be keying in data. Instead, a camera quietly recorded the container ID, logged upon its arrival. And it tagged the shipment to a specific production line. All without a single […]

CEO & Co-founder

It’s 2:14 PM at a busy CFS gate. A trailer rolls in. The container is old, dusty and sun faded. The number is readable, but only if you look closely. The driver wants to move fast. The queue behind him is growing. The gate operator does what they have always done. Reads the container number. […]

CEO & Co-founder

Modern logistics depend on speed. Accuracy and visibility keep logistics moving. Across container yards and CFS hubs… teams still face blind spots. They rely on manual checks and delayed data. This leads to missed damages and inefficient movement of assets. Logistics teams can see clearly by combining cameras with computer vision. They can understand and […]

CEO & Co-founder