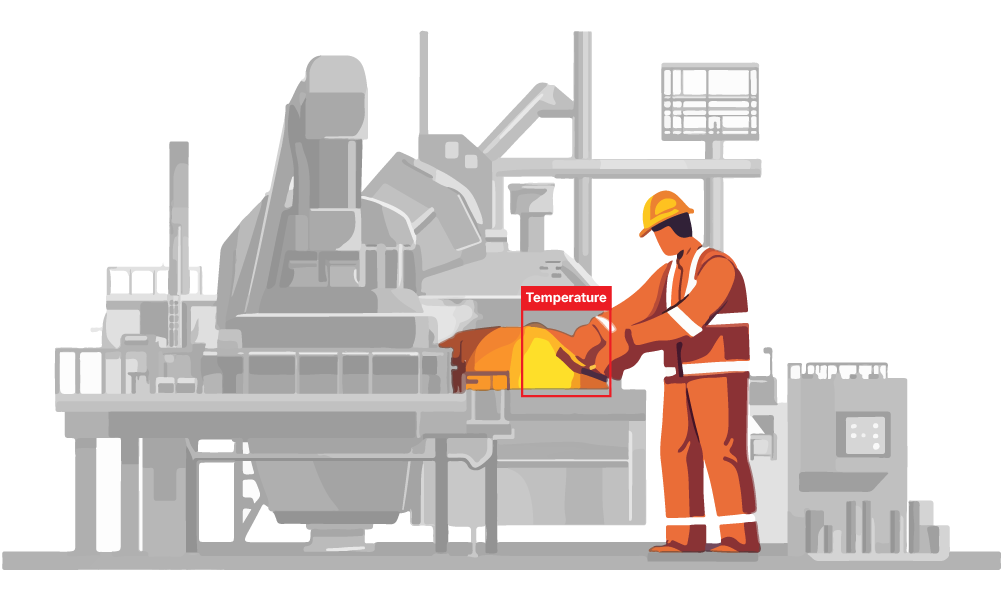

HOT METAL TEMPERATURE VALIDATION

Ensure thermal accuracy. Prevent overheating. Maintain metallurgical precision in every pour.

In the steel industry, even a few degrees can determine the success or failure of casting, rolling, or quenching. Manual temperature checks using handheld pyrometers or spot sensors are often delayed, inaccurate, or dangerously close to molten zones.Hot Metal Temperature Validation uses non-contact thermal imaging and AI analysis to provide continuous, real-time monitoring of molten metal and hot surfaces, ensuring exact thermal thresholds are maintained at each critical step, from ladle to line.

Handheld devices offer point readings that dont reflect true thermal spread or gradient.

Close-proximity measurements expose workers to extreme heat and radiant zones.

Failure to maintain optimal temperatures leads to poor grain structure or unwanted defects.

Temperature anomalies are often detected too late, after casting or forming errors have occurred.

Monitors temperature across entire metal surfaces using AI-enabled thermal cameras.

Alerts operators instantly when metal temperatures move beyond safe ranges.

Provides heat distribution maps to detect hotspots, cold zones, and uneven thermal flows.

Syncs with casting or rolling controls to auto-adjust feed rates or cooling cycles.

We begin by identifying key stages where temperature accuracy is essential, such as ladle pouring, tundish levels, rolling exit, or pre-quench zones.

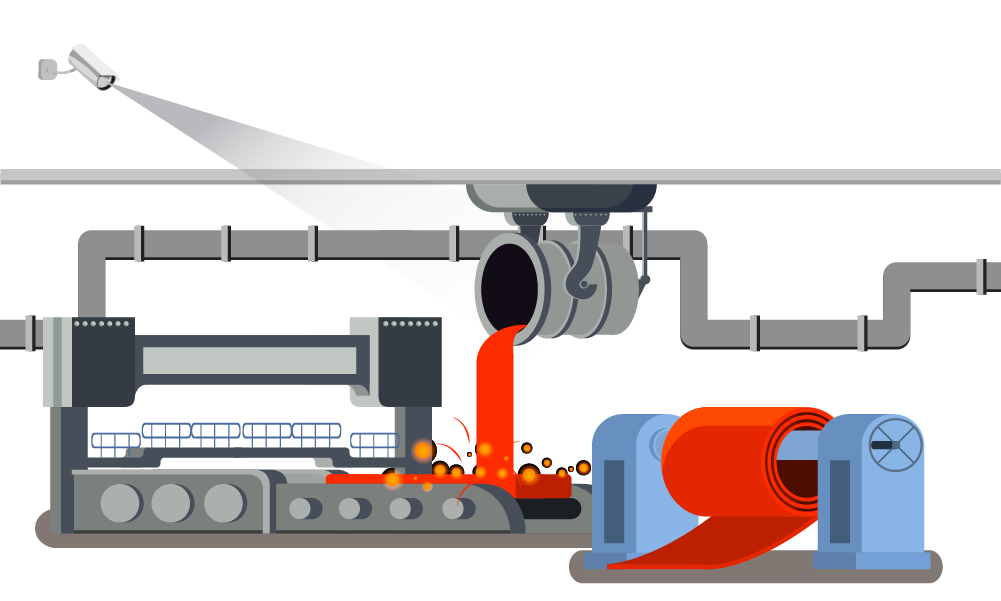

Thermal cameras are selected and calibrated for extreme heat ranges (800°C 1650°C) and placed at safe, shielded observation points using industrial-grade enclosures.

AI models are trained on visual + thermal data to correlate metal color, glow, and behavior with accurate temperature bands across steel grades and process variations.

Live thermal maps and status alerts are integrated with the control room interface. Auto-alerts are triggered for overheating, heat loss, or uneven flow, enabling timely intervention.

Stay updated with the trending and most impactful tech insights. Check out the expert analyses, real-world applications, and forward-thinking ideas that shape the future of AI Computer Vision and innovation.

7:45AM at a busy automotive parts manufacturer. A delivery truck arrived at the dock. Usually, supervisors would take 10 minutes to scan paperwork. They’d also be keying in data. Instead, a camera quietly recorded the container ID, logged upon its arrival. And it tagged the shipment to a specific production line. All without a single […]

CEO & Co-founder

It’s 2:14 PM at a busy CFS gate. A trailer rolls in. The container is old, dusty and sun faded. The number is readable, but only if you look closely. The driver wants to move fast. The queue behind him is growing. The gate operator does what they have always done. Reads the container number. […]

CEO & Co-founder

Modern logistics depend on speed. Accuracy and visibility keep logistics moving. Across container yards and CFS hubs… teams still face blind spots. They rely on manual checks and delayed data. This leads to missed damages and inefficient movement of assets. Logistics teams can see clearly by combining cameras with computer vision. They can understand and […]

CEO & Co-founder