How AI and Computer Vision Are Revolutionizing Quality Control in Manufacturing

Ruchir Kakkad

CEO & Co-founder

Artificial Intelligence (AI) and Computer Vision consist of algorithms, cameras, and computing hardware that allow machines to interpret visual information. In manufacturing, these technologies replace or augment human inspection by capturing images or video of products, then analyzing them with deep learning models to detect defects, measure dimensions, or verify assembly. Unlike simple image filters, AI-driven systems learn from data, adapting to new product lines and lighting conditions, enabling consistent, high-speed visual inspection across vast production volumes.

Today’s factories demand zero-defect outcomes, rapid throughput, and strict compliance. Manual inspections are slow, inconsistent, and error-prone; traditional rule-based vision systems lack the flexibility to handle variations in product appearance. AI and Computer Vision transform quality control into a proactive, data-driven process. By continuously monitoring every item, manufacturers minimize scrap, reduce rework costs, and accelerate production cycles. Ultimately, integrating these smart manufacturing technologies is critical for maintaining competitiveness and meeting increasingly stringent customer and regulatory demands.

Computer Vision in manufacturing refers to using cameras, imaging sensors, and AI algorithms to automatically inspect products, components, and processes. The foundation of this technology relies on high-resolution industrial cameras that provide detailed images under variable lighting conditions, ensuring consistent visual data capture regardless of environmental changes. Scanners and 3D sensors work alongside these cameras to enable depth perception for precise dimensional checks, allowing manufacturers to verify measurements with submillimeter accuracy.

Edge computing devices, including GPUs, Jetson, and Ambiq chips, run AI inference directly onsite with minimal latency, eliminating the need for cloud processing and enabling real-time decision making. Deep learning models form the intelligence layer, utilizing Convolutional Neural Networks (CNNs) for classification tasks, object detection algorithms like YOLOv5 and Faster R-CNN for locating defects, and segmentation networks such as U-Net and Mask R-CNN for pixel-level analysis. Optical Character Recognition (OCR) technology complements these systems by reading and verifying text on labels, codes, or serial numbers in real time, ensuring complete product traceability.

Rule-Based vs. Data-Driven- Traditional machine vision relies on static rules (thresholds, edge filters) that must be manually tuned for each product and lighting condition. In contrast, AI-driven computer vision learns from large datasets, adapting to product variations without manual reprogramming.

Scalability and Adaptability- Traditional systems often require significant downtime to retune when products or environments change. AI-based systems can retrain on new images quickly, scaling across multiple lines or locations.

Contextual Understanding- AI models can distinguish between benign variations (e.g., small color shifts) and true defects, reducing false positives and unnecessary rejects.

Deep Learning, specifically CNNs, enables machines to automatically learn hierarchical features from images. Early layers capture edges and textures, while deeper layers identify complex shapes. In quality control applications, classification models serve as the primary decision-making tool, determining if a product meets standards or contains defects that require attention. Object detection models, particularly YOLOv5 and Faster R-CNN architectures, excel at locating and labeling multiple defects or components within a single image, providing comprehensive analysis without missing critical issues. Segmentation models like U-Net and Mask R-CNN take this analysis further by providing pixel-level maps of defects, which proves crucial for measuring crack sizes, defect areas, and understanding the severity of quality issues.

WebOccult leverages these architectures to develop AI-powered manufacturing solutions that identify scratches, misalignments, or missing parts with over 9599% accuracy.

AI models deployed on edge computing devices (like NVIDIA Jetson AGX Orin or Ambiq microcontrollers) process images in milliseconds. The instant pass/fail capability represents a fundamental shift in quality control, where defective parts trigger immediate rejection signals that prevent flawed items from proceeding down the production line, eliminating the possibility of contaminating entire batches. Automated sorting and rework systems work seamlessly with these decisions, ensuring good units continue through the production process while flawed ones are automatically steered to designated rework bins for correction or disposal. Perhaps most importantly, these systems enable process adjustments in real-time, where emerging defect patterns such as welding anomalies trigger alerts to operators or automatically adjust machine parameters to prevent future defects.

By embedding AI inference at the edge, WebOccult ensures every production anomaly is detected and addressed instantly, fulfilling the promise of AI-driven quality control.

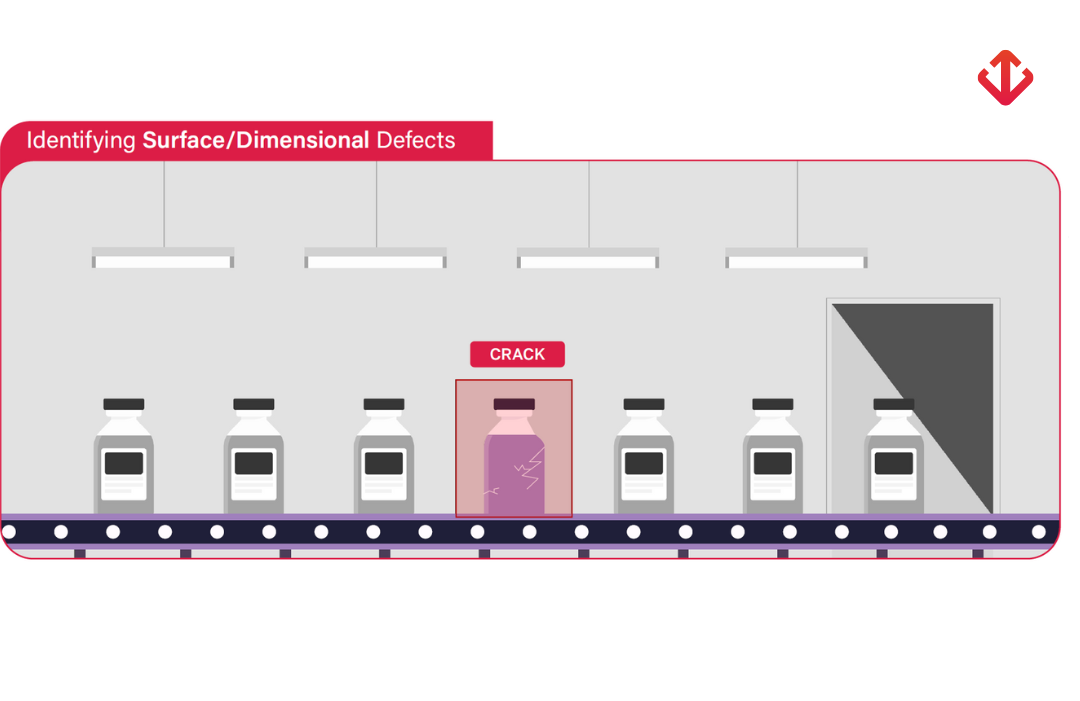

AI-powered vision systems identify a broad spectrum of defects with remarkable precision and consistency. Surface scratches and dents that might be invisible to the human eye are detected with microscopic accuracy on metals, plastics, or composite materials, ensuring that even the smallest imperfections don’t compromise product quality. The systems excel at identifying cracks and fractures through pixel-level segmentation that can locate micro-cracks in ceramics, glass, or welds before they propagate into catastrophic failures. Textural inconsistencies present another area where AI vision systems demonstrate superior capability, identifying weave irregularities in textiles or grain errors in veneers that could affect both aesthetics and functionality. Perhaps most critically, these systems confirm that every component is present and correctly positioned, whether it’s resistors and capacitors on PCBs or mechanical parts in complex assemblies, preventing costly functional failures downstream.

WebOccult’s defect classification solutions categorize each anomaly, e.g., “scratch,” “dent,” “crack,” “missing component”, facilitating targeted root-cause analysis and continuous improvement.

Maintaining surface quality is essential for brand reputation, and AI vision systems provide comprehensive inspection capabilities across various surface types and conditions. Paint and coating uniformity analysis identifies subtle variations in sheen, color, or thickness on automotive panels, consumer electronics, or coated pipelines that could indicate process problems or material defects. Reflective material analysis presents unique challenges that these systems overcome through multi-angle imaging and polarization filters that mitigate glare, enabling accurate inspection of glossy surfaces that traditional systems struggle with. Texture continuity verification ensures consistent weave patterns in fabrics or grain structures in wood products, catching tears, misalignments, or inconsistencies early in the production process before they reach customers.

Precision is vital when parts must fit with micron-level tolerances, and AI vision systems achieve this through sophisticated measurement techniques. 3D profiling with stereo and structured light cameras captures comprehensive depth data to measure height, width, and alignment with submillimeter accuracy, ensuring that even the most demanding aerospace and medical device applications meet their stringent requirements. 2D dimensional verification complements this capability by using high-resolution imaging to confirm hole spacing, edge alignment, and angular tolerances instantaneously, eliminating the time-consuming manual measurement processes that can bottleneck production. Real-time tolerance checking represents the pinnacle of this technology, enabling inspection of up to 500 units per minute while validating every critical dimension as parts move through inspection stations without slowing the production line.

As product complexity grows, verifying correct assembly becomes increasingly crucial, and WebOccult’s assembly verification tools provide comprehensive confirmation of each build step. Wire harness and connector checks ensure proper routing and fully seated connections in automotive or industrial equipment, preventing electrical failures that could compromise safety or functionality. Screw presence and torque validation represents a sophisticated application where AI analyzes visual cues such as screw head depth to ensure each fastener is not only present but also properly tightened without being over-torqued, which could damage threads or components. Component orientation checks provide the final layer of verification, confirming that integrated circuits, sensors, or mechanical parts are oriented according to CAD specifications, preventing functional failures that might not be discovered until final testing or field deployment.

Detection rates consistently exceed 95.99% accuracy levels, with WebOccult’s deep learning models identifying microscopic defects or subtle color variances that human inspectors routinely miss due to fatigue, distraction, or the limitations of human vision. The elimination of human variability represents a fundamental advantage, as AI systems apply identical criteria consistently across every shift, every day, removing errors caused by subjective judgment, fatigue, or inconsistent training between different operators, ensuring a uniform quality standard throughout production.

High throughput capabilities enable AI vision cameras to inspect 200 & 500 items per minute, compared to the 2030 items that human inspectors can reasonably handle, dramatically reducing inspection bottlenecks that often constrain production capacity. This automation optimizes labor allocation by freeing skilled quality control personnel from repetitive inspection tasks, allowing them to focus on higher-value activities like root cause analysis and continuous improvement initiatives that drive long-term operational excellence. The uninterrupted production capability ensures that manufacturing lines maintain peak speed without pausing for manual batch inspections, as AI systems make instant pass/fail decisions that keep products flowing seamlessly through the production process.

Rich defect analytics capabilities ensure that every defect is automatically logged with precise timestamp, location, and severity data, creating a comprehensive database that transforms quality issues from isolated incidents into valuable insights for process improvement. Trend monitoring analyzes defect patterns by shift, machine, or material lot to uncover systematic process flaws, enabling proactive maintenance and process adjustments rather than reactive responses to quality problems. Continuous model retraining represents the self-improving nature of these systems, where AI pipelines automatically incorporate new defect imagery into retraining cycles, continuously refining accuracy and reducing false positives as operations evolve and new challenges emerge.

Rapid deployment across multiple production lines becomes possible once AI models are trained on a specific product, as these systems can be rolled out to additional lines or global facilities with minimal additional data collection or configuration time. Adaptation to product changes demonstrates remarkable flexibility, where new product variants or design updates require only minor retraining rather than the lengthy reprogramming cycles that traditional rule-based systems demand, significantly reducing downtime during product transitions. Modular expansion capabilities allow factories to start with a single AI inspection station and gradually scale to dozens of cameras and edge devices as needs grow, with WebOccult’s scalable vision solutions ensuring seamless integration and expansion without disrupting existing operations.

![]()

Modern manufacturing needs more than manpower, it needs machine vision. Our AI vision systems bring speed, precision, and consistency to your shop floor. They cut down human error, ensure product quality, and streamline decision-making, so every process runs smarter, faster, and more reliably.

Common Manufacturing Challenges:

Manual errors in traditional processes lead to significant inaccuracies that cost both time and resources, creating cascading effects throughout the production line that can impact delivery schedules and customer satisfaction. Operational inefficiencies often go undetected in complex manufacturing environments, but identifying and addressing these inefficiencies can significantly impact productivity and output, making the difference between profitable and unprofitable operations. Safety risks present an ongoing concern in manufacturing environments, where ensuring the protection of workers and compliance with increasingly stringent safety regulations requires constant vigilance and sophisticated monitoring systems. Poor quality control remains a persistent challenge, as maintaining high product quality while minimizing defects is essential for customer satisfaction and brand reputation in competitive markets.

Quality/Quantity/Time Control

AI-powered Machine Vision quality control systems are very helpful in maintaining high product quality. Catch defects that escape human eyes, reduce them by up to 50%, and deliver flawless products.

Applications:

Additional Solutions:

WebOccult differentiates itself as a strategic partner for manufacturers embedding AI in manufacturing. Our comprehensive approach includes:

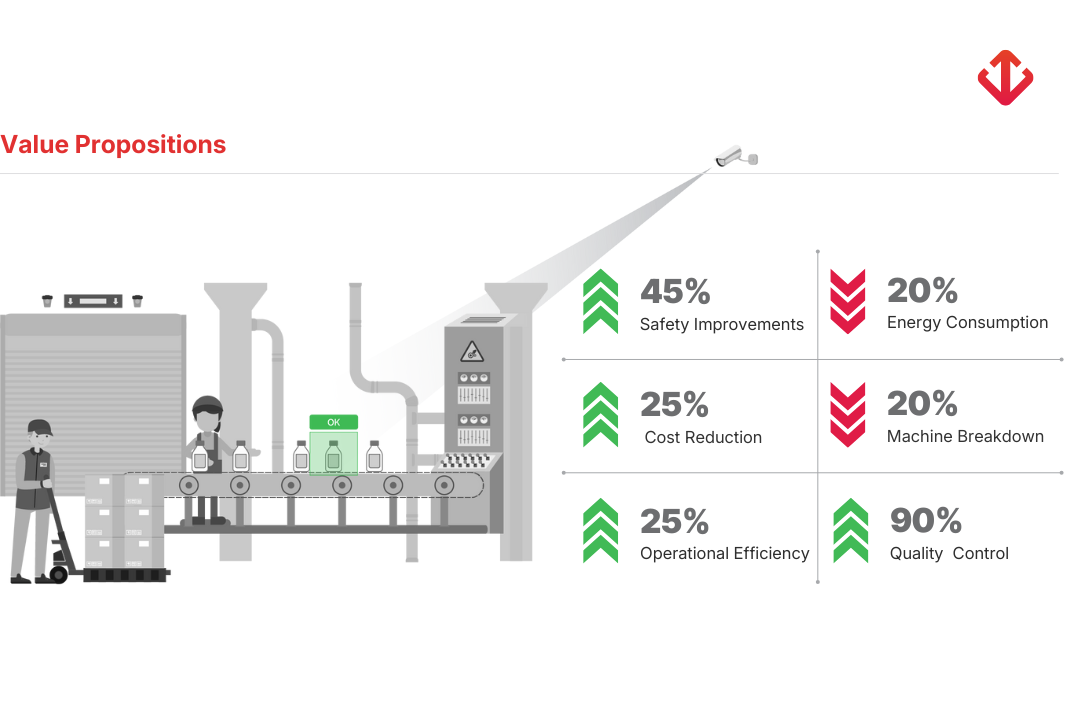

Quality control has evolved into a front-line competitive advantage for smart factories. By integrating AI and computer vision in manufacturing, companies unlock:

As quality expectations rise and product architectures become more complex, manufacturers adopting these smart manufacturing technologies will outperform those relying on legacy methods. Implementing AI for quality control is not just an enhancement, it’s a strategic imperative.

With WebOccult’s expertise in custom deep learning models, edge-based deployments, and seamless system integration, your production lines can transform into self-healing, self-optimizing engines of excellence.

Schedule a consultation or demo. Let us show you how our AI-powered manufacturing solutions can elevate your QC to unprecedented levels, ensuring every part, every product, and every batch meets the highest standards of precision and reliability.