Customer

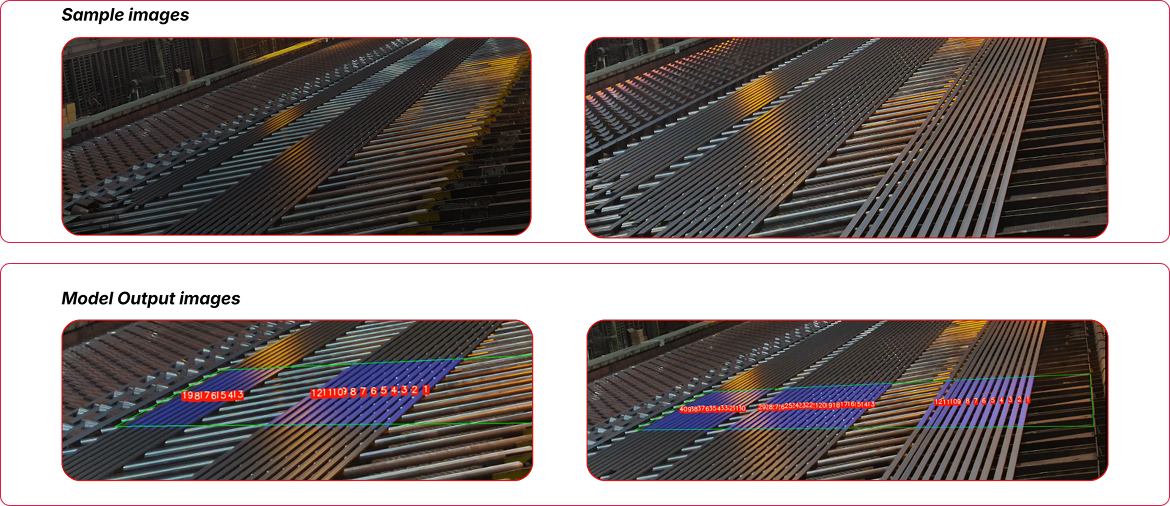

One of Japan’s leading steel manufacturing plants.

Project Details

- Duration: 1 Month +

Technologies:

- Deep Learning

- OpenCV

- Python

- PyQt

- Edge Computing devices

- SQLlite

One of Japan’s leading steel manufacturing plants.

Technologies:

Accuracy

Stay updated with the trending and most impactful tech insights. Check out the expert analyses, real-world applications, and forward-thinking ideas that shape the future of AI Computer Vision and innovation.

7:45AM at a busy automotive parts manufacturer. A delivery truck arrived at the dock. Usually, supervisors would take 10 minutes to scan paperwork. They’d also be keying in data. Instead, a camera quietly recorded the container ID, logged upon its arrival. And it tagged the shipment to a specific production line. All without a single […]

CEO & Co-founder

It’s 2:14 PM at a busy CFS gate. A trailer rolls in. The container is old, dusty and sun faded. The number is readable, but only if you look closely. The driver wants to move fast. The queue behind him is growing. The gate operator does what they have always done. Reads the container number. […]

CEO & Co-founder

Modern logistics depend on speed. Accuracy and visibility keep logistics moving. Across container yards and CFS hubs… teams still face blind spots. They rely on manual checks and delayed data. This leads to missed damages and inefficient movement of assets. Logistics teams can see clearly by combining cameras with computer vision. They can understand and […]

CEO & Co-founder