Traffic Flow Optimization

Improve mobility and reduce congestion with AI-supported traffic management.

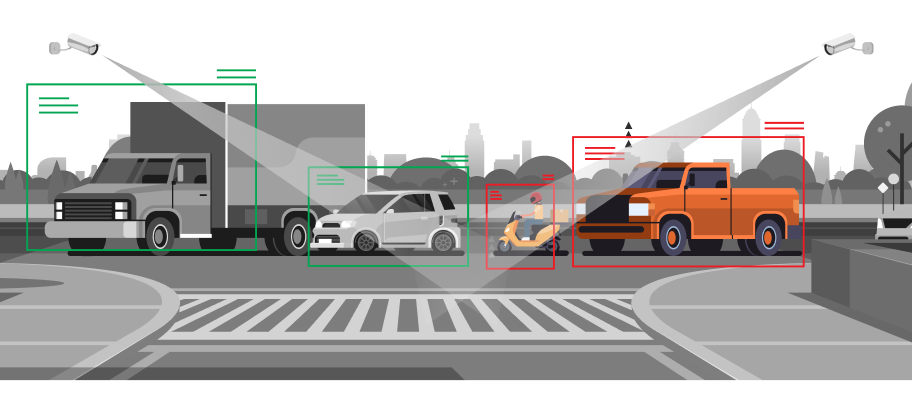

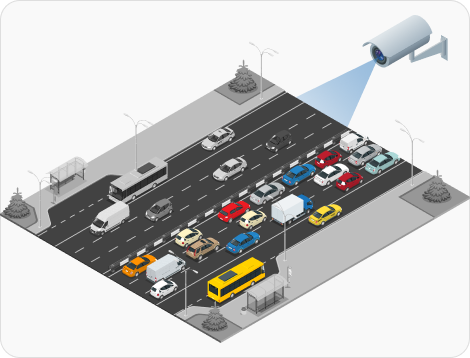

Industrial zones, ports and urban areas experience frequent congestion due to manual traffic management. It leads to delays which can cause financial losses. AI and computer vision can help optimize traffic by analyzing real-time data around vehicle movement to reduce wait times and enhance safety of the roads.

Heavy traffic at intersections causes bottlenecks which stop vehicle movements, causing inefficiencies.

AI can dynamically adjust traffic signals to balance vehicle flow and reduce congestion.

Traditional traffic management doesn’t do continuous tracking or predictive analytics.

AI processes real-time CCTV footage to understand traffic patterns and optimize management accordingly.

Manual scheduling and route planning can cause delays, congestions and increased fuel costs.

Real-time cargo flow analysis, dock availability and route conditions help ensure overall effective transportation.

Heavy machinery, largo cargo and blind spots increase the chances of accidents at docks and container yards.

Computer vision detects potential risks in real time and alerts the drivers and logistics coordinators.

High-volume transport environments that deal with large cargo can use AI to streamline operations, reduce delays and improve safety.

We analyze cargo movement, vehicle flow and dock operations to integrate AI optimization models.

The system learns traffic bottlenecks, loading/unloading patterns and optimal routing for smooth transport.

AI tracks the fleet movement in real time, identify congestion points and potential hazards for proactive management.

AI generated insights help minimize delays, optimize resource allocation and improve future logistics planning.

Stay updated with the trending and most impactful tech insights. Check out the expert analyses, real-world applications, and forward-thinking ideas that shape the future of AI Computer Vision and innovation.

7:45AM at a busy automotive parts manufacturer. A delivery truck arrived at the dock. Usually, supervisors would take 10 minutes to scan paperwork. They’d also be keying in data. Instead, a camera quietly recorded the container ID, logged upon its arrival. And it tagged the shipment to a specific production line. All without a single […]

CEO & Co-founder

It’s 2:14 PM at a busy CFS gate. A trailer rolls in. The container is old, dusty and sun faded. The number is readable, but only if you look closely. The driver wants to move fast. The queue behind him is growing. The gate operator does what they have always done. Reads the container number. […]

CEO & Co-founder

Modern logistics depend on speed. Accuracy and visibility keep logistics moving. Across container yards and CFS hubs… teams still face blind spots. They rely on manual checks and delayed data. This leads to missed damages and inefficient movement of assets. Logistics teams can see clearly by combining cameras with computer vision. They can understand and […]

CEO & Co-founder