We hear a lot that AI is the future of manufacturing. No, it’s not, not anymore. Some also say that AI will replace human labor. No, it won’t. You need not wait for the future; AI is the present now. It has already found its place in the factories in different ways. And it’s not replacing human labor, it’s making them smarter, faster and more productive.

One such AI based technology is Computer Vision which is implemented across the manufacturing facility, be it the entry points or assembly line. Computer Vision gives superpowers to the CCTVs and enables a real-time alert system that makes the factory floor safer, more productive and overall efficient.

In this blog, we’ll look at the 7 top use cases of AI-powered Computer Vision and see how it’s making the operations and workforce better.

1. Optimizing Labor for Productive Shift Hours

Idle time, disorganized workflows and worker fatigue are some real problems in manufacturing. Computer Vision helps in tracking such efficiencies by monitoring the worker movements, bottlenecks and productivity so you can make process improvements accordingly.

When implemented on the assembly lines, it gives insights on task completion times and worker movement patterns. It lets you identify the inefficient areas and improve the productivity of the workers.

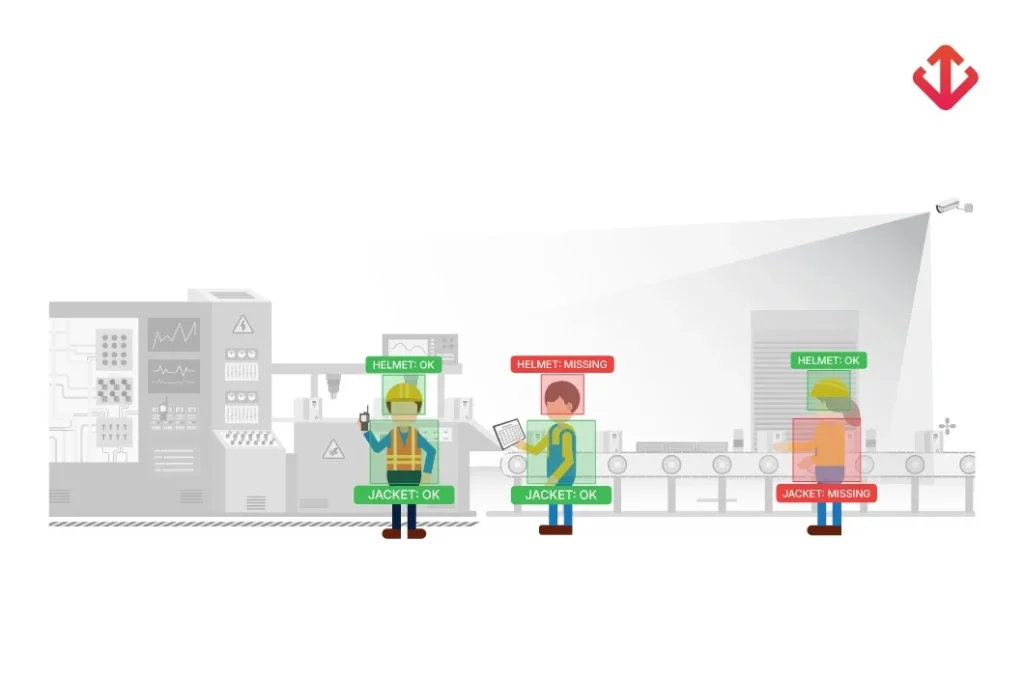

2. Worker Safety and Compliance

Safety of the workers is always the top priority in manufacturing. Often, multiple places in the facility are danger zones and workers have to be cautious. Computer Vision alerts you when a worker is in the zone or not following the safety protocols in general–not wearing the helmet, gloves, vests, etc.

It also monitors the worker postures to prevent ergonomic injuries, detects entry in restricted areas and improper use of machines. As this sends real-time alerts to the supervisors, workplace accidents can be greatly reduced by implementing a modern safety culture.

3. Quality Control for Defect-Free Production

Success of manufacturing depends solely on the product quality and manual inspection always has a scope for errors. Computer vision automates this process by identifying defects like scratches, misalignments, or material inconsistencies with pinpoint accuracy.

BMW uses AI-driven vision systems in its car manufacturing units. These systems scan every vehicle part, ensuring it meets predefined quality standards. BMW reported a significant reduction in defects after integrating computer vision, which has improved customer satisfaction and reduced rework costs.

By enabling consistent quality checks in real time, manufacturers can maintain their reputation while minimizing waste.

4. Hazard Detection for Safer Workplaces

Fire, chemical spills, or even unauthorized access to certain areas not only disrupt the routine operations but also compromise safety. Computer Vision systems are utilized to detect such situations and send real-time alerts to the authorities for faster responses.

The AI system can reduce the response times by up to 60% and helps minimize damage and ensure worker safety.

5. Real-Time Occupancy Monitoring

Real-time occupancy tracking through Computer Vision creates a digital twin of the workspace for monitor and manage space usage. This helps run the operations smoothly and eliminates inefficiencies.

Manufacturers can employ real-time occupancy monitoring in factories to balance workforce distribution. This ensures optimal space utilization, prevents overcrowding, and maintains safety regulations.

6. Batch and Inventory Monitoring

Traceability and inventory management are very important for large-scale manufacturers for tracing defective products back to their source and optimizing inventory levels. Computer Vision systems, you can easily track production batches in real time, ensuring complete visibility throughout the supply chain.

In case of recalls, tracing the defective products can preserve brand reputation and save significant resources too.

7. Enhancing Predictive Maintenance

Another transformative use case is predictive maintenance. Computer Vision systems analyze machine behavior to detect early signs of wear and tear, preventing sudden breakdowns. Predictive maintenance is well known to have helped manufacturers save costs and avoid production delays.

Real-World Impact of Computer Vision

Companies like Airbus are already using AI-powered Computer Vision in their operations. Let’s see how:

Problem

Airbus faced a time-consuming and error-prone final assembly process. Their process heavily relied on manual inspection and data entry. Of course, it was inefficient and susceptible to human error.

Solution

They started utilizing Computer Vision for analyzing their video feeds from the assembly line. It automatically detected and logged major assembly steps. The AI system eliminated the need for manual intervention and reduced the risk of human error.

Outcome

The implementation of this AI-powered solution has led to:

- Hire efficiency as automated inspection process saved time and reduced labor costs.

- Improved accuracy as AI system accurately identified and minimized errors.

- Enhanced quality control with early detection of potential issues.

- Data-driven insights that helped optimize future manufacturing processes.

The Future

With AI and IoT technologies evolving, manufacturers expect even greater efficiencies and insights. Advanced systems can integrate seamlessly with IIoT data and add value by analyzing human activities between automated processes. This leads to significant increases in output, especially when responding to changing demands or resource constraints.

Are you ready to leverage computer vision to transform your manufacturing processes? Get in touch with us to know more.