How Computer Vision Makes Factories Safer

Ruchir Kakkad

CEO & Co-founder

The manufacturing industry has been utilizing technologies for digitalization. Yet, even with the different technologies at play, the manufacturing industry has been one of the largest contributors of workplace injuries. With the UN claiming 2.78 million deaths every year due to workplace-related accidents and sicknesses, safety is a major issue.

So, what can be done to address the risk of operating heavy machinery and handling hazardous material? Do they have to change the industrial practices? Is it going to be another technology?

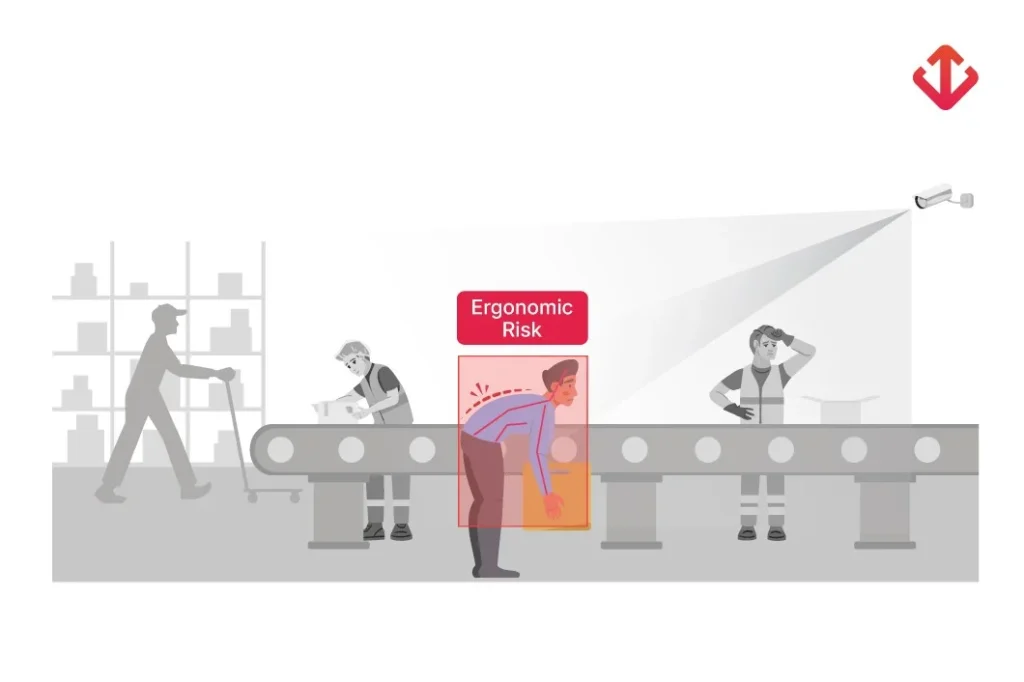

Computer Vision helps industries keep a close eye on the happenings in their facility and help the authorities successfully implement the set guidelines. It also provides real-time alerts to the authorities when something goes wrong. Thus, they are in a better position to act swiftly and mitigate the same.

Lets talk in detail about the role of Computer Vision in helping manufacturers mitigate risks, promote safety and protect their workforce.

Computer Vision uses advanced cameras and AI systems to analyze visual data. Its like a continuous monitoring system that gives intelligent alerts and helps enforcing the safety protocols.

Heres how computer vision is shaping a safer manufacturing landscape:

Unintentional entry into hazardous zones is one of the leading causes of workplace injuries in manufacturing. Workers may accidentally step into areas where heavy machinery is in operation or approach zones with harmful chemicals.

How It Helps:

Computer vision systems track the precise location and movement of workers on the factory floor. They create virtual boundaries around dangerous areas, ensuring employees stay within safe zones. These systems can identify risky movements, such as walking into the path of a moving conveyor crane or nearing a high-temperature furnace, and trigger alerts to warn the worker or halt machinery to prevent accidents.

Additionally, these systems can adapt to dynamic environments by:

Enforcing the safety measures and continuous monitoring of the adherence is made easy by Computer Vision. It checks for protective measures like wearing helmets, gloves, goggles and protective suits.

How It Helps:

Computer vision automates the enforcement of safety rules by monitoring compliance with protective gear requirements. Cameras equipped with AI can:

For example, in chemical plants, workers entering mixing units without full protective suits can be flagged immediately, reducing the risk of exposure. By removing human bias and fatigue, computer vision ensures consistent enforcement, even during peak production hours.

Malfunctioning machinery and unsafe environmental conditions can lead to dangerous accidents. Continuous surveillance of equipment breakdowns, leaks, or fires is much needed.

How It Helps:

Computer vision-powered sensors continuously monitor factory environments to ensure operational safety. These systems can:

For instance, sensors in a paint shop can detect harmful fumes and activate ventilation systems automatically. In factories handling flammable substances, cameras can spot sparks or overheating components, preventing fires before they ignite.

Manufacturing plants are generally of large sizes, due to which they are vulnerable to trespassing by intruders or even wildlife. This is a risk to the workforce, property and operations.

How It Helps:

Computer vision systems can monitor vast perimeters 24/7, identifying and analyzing suspicious activities. They can:

For example, the system alerts the authorities if an unauthorized person tries to enter a restricted zone or if there is an animal in the way or the premises.

Improper handling of machinery or ignoring safety signs most likely leads to workplace injuries. However, workers often skip steps in safety protocols to save time, leading to increased risks.

How It Helps:

Computer vision analyzes behavior patterns and flags unsafe actions in real time. It can:

For instance, suppose a working is manually adjusting a working robotic arm in an automotive assembly plant, the system might right away notify the supervisor. The swift action can prevent potential injury.

When accidents occur, finding out the causes is important to prevent it from happening again. But if the data is not enough, it is not possible to identify the actions that led to the accident.

How It Helps:

Computer vision systems provide detailed video logs of incidents, enabling faster, more accurate investigations. They can:

This approach helps in resolving incidents and provides opportunities to refine safety strategies.

Timely response means everything during an emergency. If there is a delay in acting to fires, gas leaks, or medical emergencies, the consequences are severe.

How It Helps:

Computer vision systems are designed to recognize emergencies instantly. They can:

For example, in a factory handling flammable materials, the system can detect smoke and automatically trigger sprinklers while notifying the fire department, reducing response times and potential damage.

Computer Vision has introduced a paradigm shift in safety for industries. By continuously checking the safety of the workers and the workplace, it acts like a supervisor who works 24/7, totally dedicated to ensuring safety.

Want to understand how AI Computer Vision can make your plant safer? Get in touch with us for a free consultation.